Water distributing device of wastewater treatment and pulse type water distributing method thereof

A water distribution device and wastewater treatment technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, anaerobic digestion treatment, etc. Increase the mixing effect of mud and water and the effect of sufficient anaerobic reaction of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

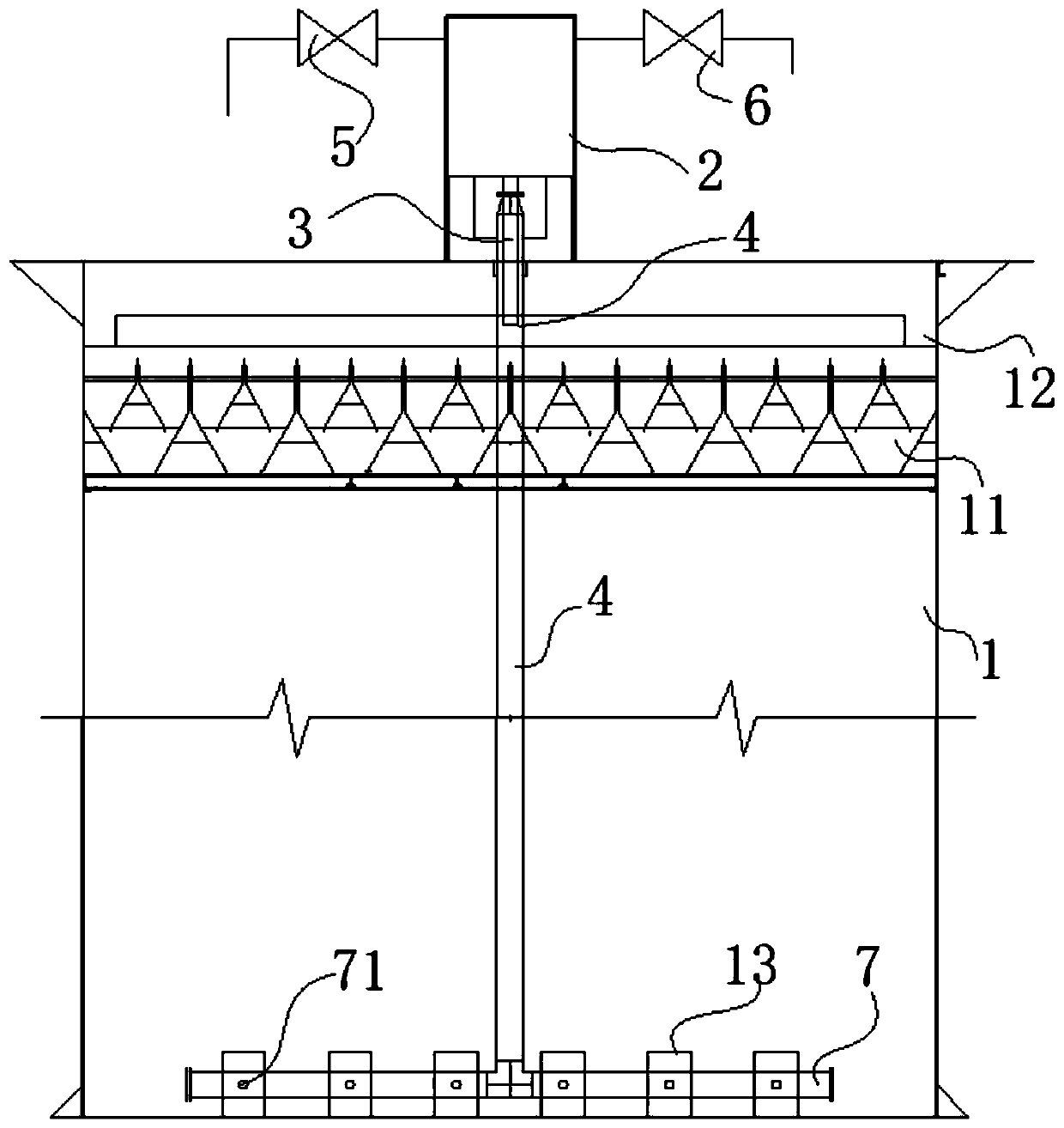

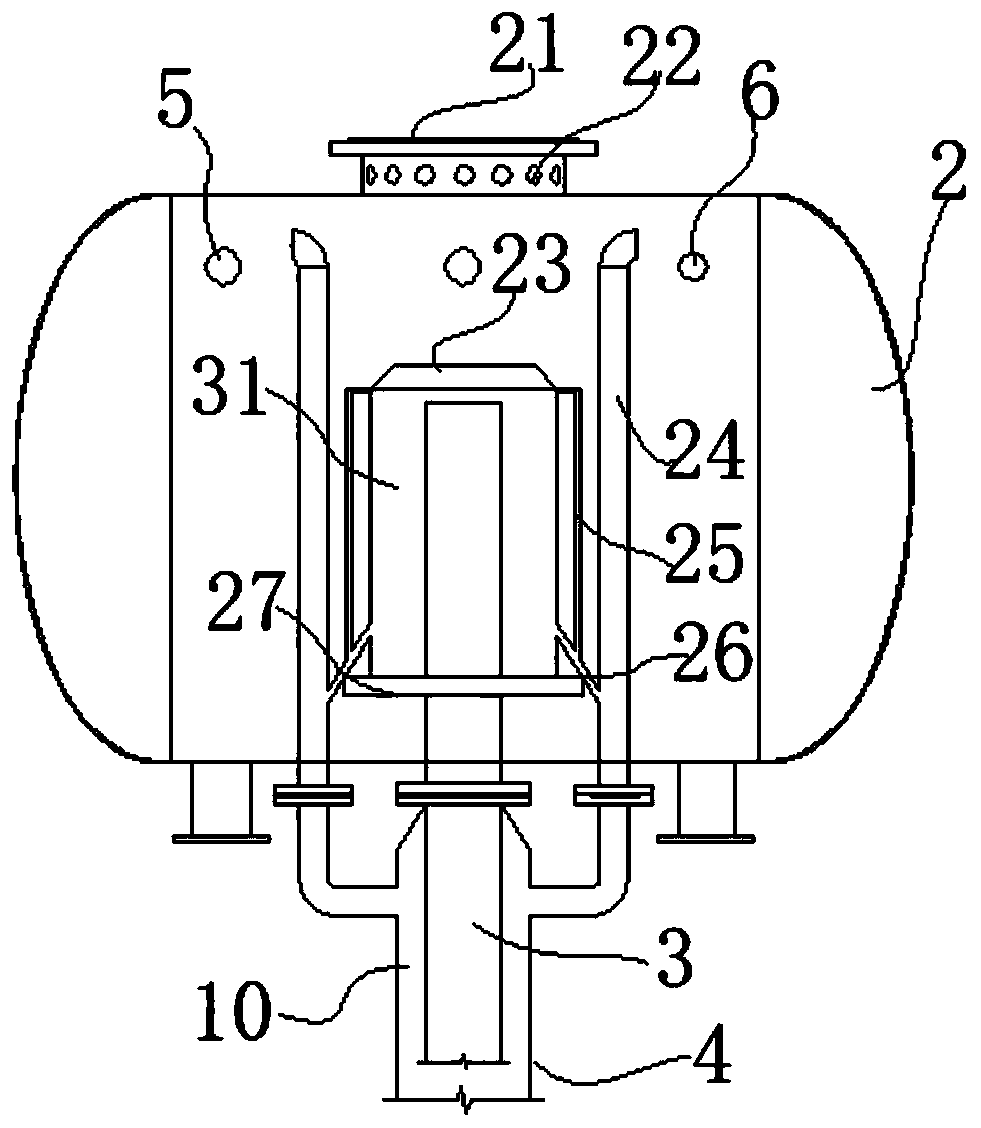

[0039] A water distribution device for wastewater treatment in this embodiment, such as figure 1 , 2As shown in . The main siphon 3, the upper part of the main siphon 3 is covered with an inverted barrel-shaped cover 23 to realize a closed space, and the lower end passes through the tank body and is inserted into the upper part of the main water distribution pipe 4 to form a pipe-in-pipe casing structure. The cover body 23 is fixed by a fixing plate 27, and the fixing plate 27 is fixed on the inner wall of the tank body; a ring cavity 31 is formed between the inside of the cover body 23 and the main siphon pipe 3, and the ring cavity 31 is externally connected with a vacuum breaking tube 28. The vacuum breaking pipe 28 is in an inverted "L" shape, and forms a siphon structure with the main siphon pipe 3. Under the action of hydraulic force, a certain degree of vacuum can be generated inside the cover body 23 to realize pulse water distribution; the main water distribution pip...

Embodiment 2

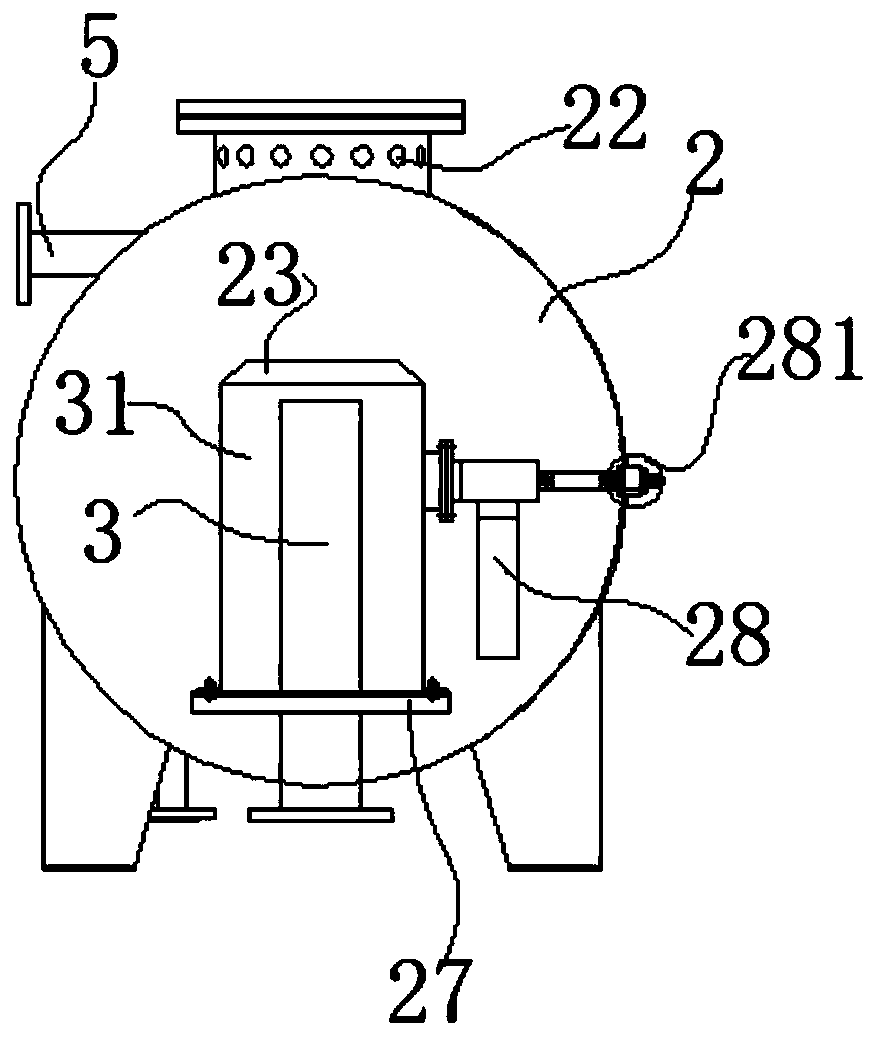

[0042] A water distribution device for wastewater treatment in this embodiment is further improved on the basis of Embodiment 1, such as image 3 As shown, after the upper part of the vacuum breaking tube 28 passes through the rotating shaft to the outside of the tank, a rotatable adjustment handle 281 is externally connected to the rotating shaft to rotate the vacuum breaking tube 28, and the rotation can be realized manually or electrically, that is, the vacuum breaking tube 28 By adjusting the handle 281 to realize swinging back and forth, it is not only beneficial to adjust the water distribution volume and pulse frequency, but also further increases the mixing effect of hydraulic agitation, that is, by adjusting the height and low of the vacuum breaking tube 28, different pulse frequencies and water distribution volumes can be adjusted to achieve Requirements for processing capacity under different working conditions.

[0043] The pulse type water distribution method of t...

Embodiment 3

[0048] A water distribution device for wastewater treatment in this embodiment is further improved on the basis of Embodiment 2, such as figure 2 As shown, between the bottom of the main siphon pipe 3 and the casing structure on the upper part of the main water distribution pipe 4, an annular gas collection chamber 10 with a top seal is formed, and the upper part of the gas collection chamber 10 is externally connected to an exhaust pipe 24, and the exhaust pipe After the top of 24 is inserted into the tank, until the top of the tank is higher than the top of the cover body 23, the breathing end of the siphon structure is formed, and the waste gas in the main water distribution pipe 4 can also be discharged; the gas collection chamber 10 is located in the pulse water distributor 2. The 4 main water distribution pipes at the bottom can quickly collect the exhaust gas in the water distribution pipe, and discharge the excess gas in time through the connected exhaust pipe 24, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com