A polishing device and method based on confocal megasonic micro-jet

A polishing device and megasonic wave technology are applied in the field of optical component processing and ultra-precision optical surface processing, which can solve the problems of large surface energy, small nozzle hole size, affecting polishing quality, etc. Time response characteristics, effect of suppressing agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The invention discloses a confocal megasonic wave micro-jet polishing scheme. The polishing scheme mainly realizes the polishing of optical elements through the micro-jet excited by the megasonic wave and the particle resonance effect, especially utilizes the emitted megasonic wave to form a liquid storage chamber. The polishing liquid inside is the propagation medium, passes through the cavity and the nozzle, and finally focuses on a point outside the nozzle; when performing processing work, the focus of the megasonic wave is placed near the surface of the processed component for polishing.

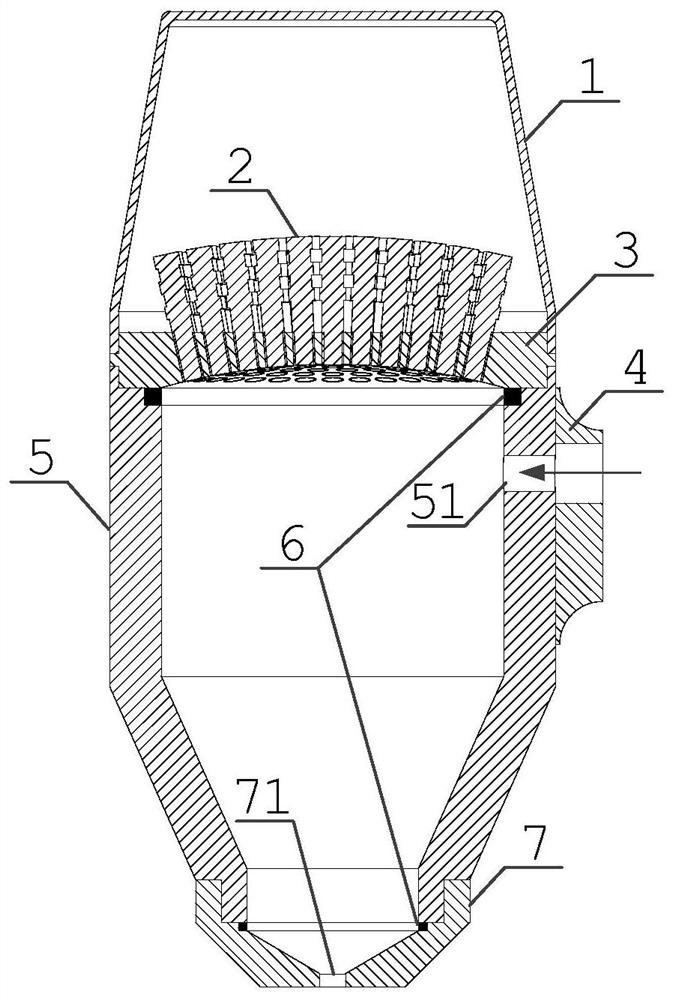

[0035] Embodiment 1 is a kind of micro-jet polishing device based on confocal megasonic wave, such as figure 1 Shown is a schematic diagram of the central section structure of the polishing device, which includes a top cover 1, a megasonic transducer 2, a transducer cluster seat 3, a connecting seat 4, a liquid storage chamber 5, a sealing ring 6, and a nozzle 7. The nozzle 7 is p...

Embodiment 2

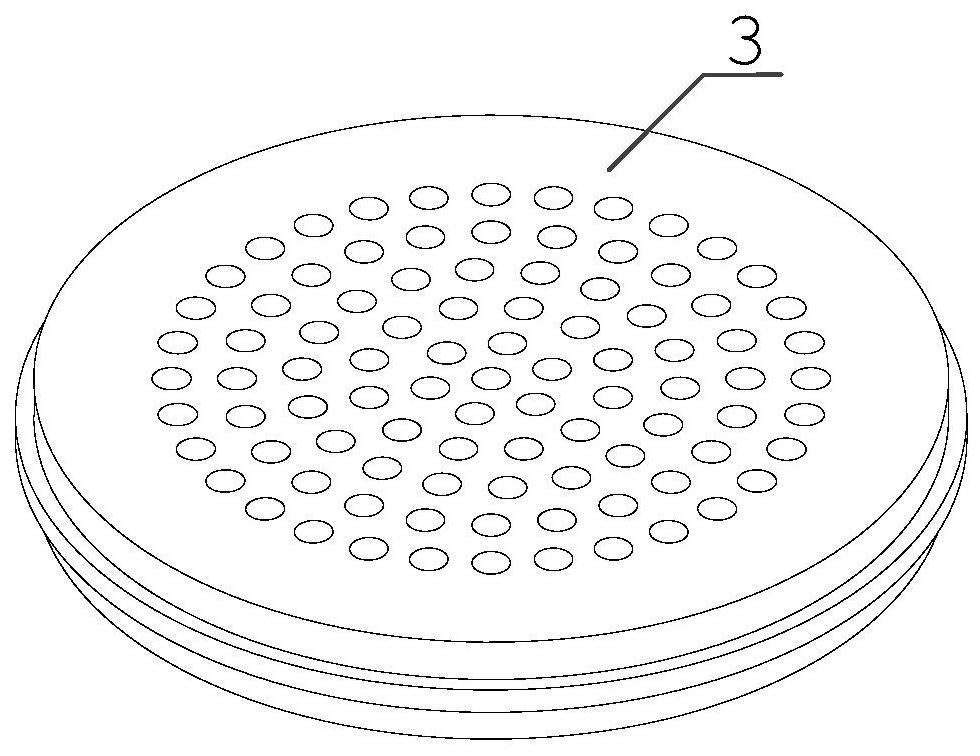

[0038] Such as figure 2 As shown, it is a three-dimensional view of the transducer cluster seat 3 in the confocal megasonic micro-fluidic polishing device. There are several transducer mounting holes for installing megasonic transducers on the transducer cluster seat 3, the number of transducer mounting holes is greater than or equal to the number of megasonic transducers used, which is Since the number of megasonic transducers actually used needs to be selected according to actual use requirements, the number of megasonic transducers can be determined according to actual needs and fixedly installed on the transducer cluster seat 3. inside the hole. In actual work, the operating frequency and power of the megasonic transducer can be adjusted through hardware or software, and the overall operating frequency and power of the transducer can be controlled by controlling the transducer driver.

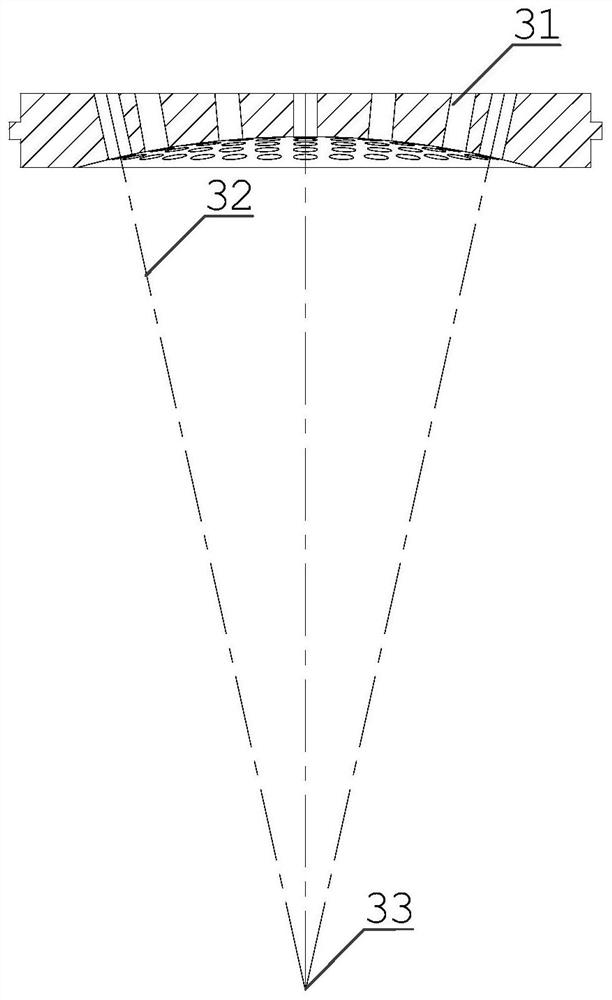

[0039] for image 3 For the transducer cluster seat 3 shown under an angle, its upp...

Embodiment 3

[0043] In the confocal megasonic-based micro-jet polishing device, the polishing liquid 8 is a liquid medium for transmitting megasonic energy, such as a stainless steel polishing liquid. In other embodiments, the polishing liquid 8 can also be other liquids that can achieve the same function. In actual operation, the liquid storage chamber must be filled with the polishing liquid 8 to serve as a conduction medium for megasonic waves.

[0044] Such as Figure 4 Shown is the schematic diagram of the transducer and its focus, the polishing fluid 8 is focused on a point outside the end face of the transducer by the megasonic wave sent by the megasonic transducer in the foregoing embodiment, and this point is the focus of the transducer, And this point has the maximum megasonic sound field intensity, and at the same time the polishing fluid exhibits the maximum jet velocity at this point.

[0045] Such as Figure 5 As shown, the overall three-dimensional view of the confocal meg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com