A kind of preparation method of composite nanomaterial hybrid membrane and hybrid membrane prepared thereby

A technology of composite nanomaterials and hybrid membranes, which is applied in the field of preparation of hybrid membranes and composite nanomaterial hybrid membranes, to achieve the effects of improving production efficiency, enhancing mechanical properties, and simple and efficient post-processing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Based on the above inventive concept, the present invention provides a method for preparing a composite nanomaterial hybrid film, which is characterized in that it comprises the following steps:

[0050] (1) dispersing the nanocellulose crystals in water to obtain a nanocellulose crystal dispersion;

[0051] (2) graphene oxide is dispersed in water to obtain graphene oxide dispersion;

[0052] (3) mixing the nanocellulose crystal dispersion liquid and the graphene oxide dispersion liquid to make a mixed dispersion liquid;

[0053] (4) Treat the basement membrane with a hydrophilic treatment solution;

[0054] (5) coating the mixed dispersion liquid on the above-mentioned treated base film to form a functional layer;

[0055] (6) After post-treatment and drying, a composite nanomaterial hybrid film is obtained.

[0056] It should be noted that, in the present invention, there is no sequence among the above steps (1), (2), and (4), and there is no sequence between step...

Embodiment 1

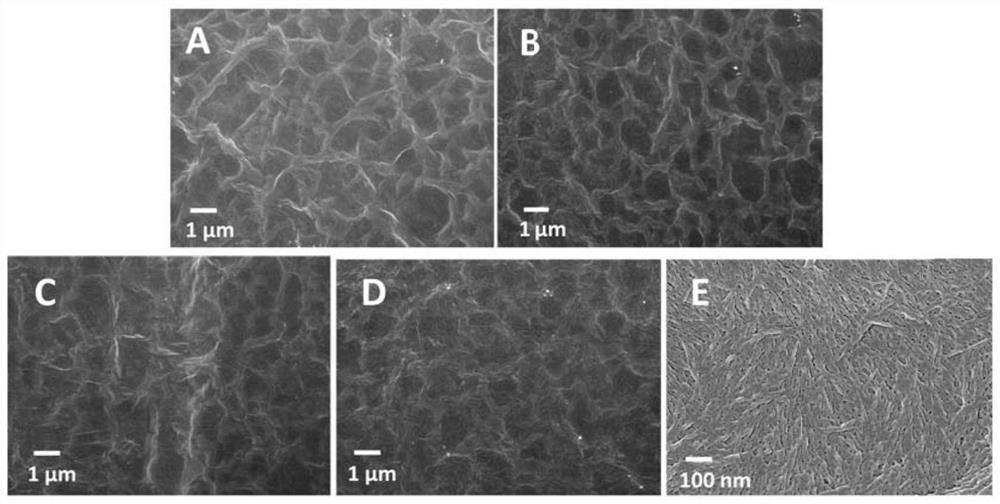

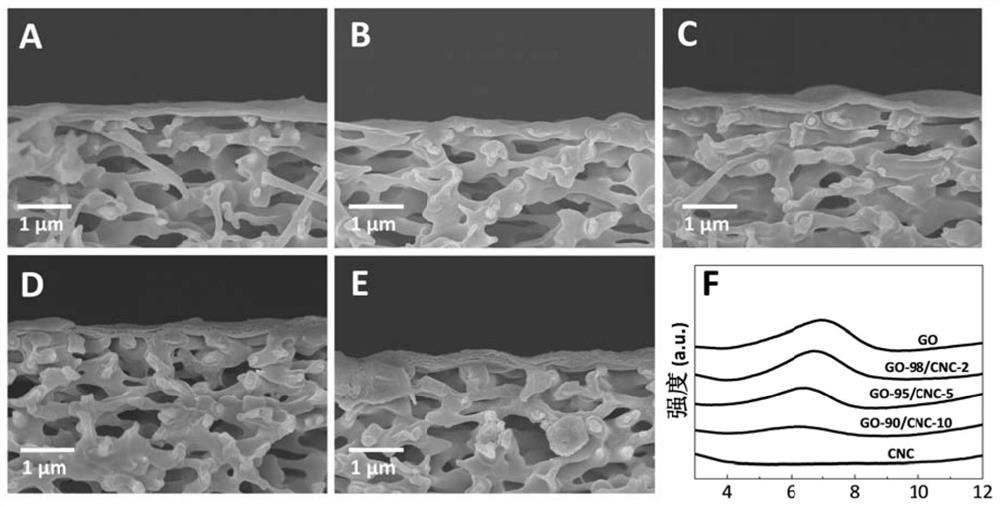

[0076] Preparation of graphene oxide (GO) dispersion: Disperse 0.025g single-layer graphene oxide (thickness is about 1nm, size 2-10μm) in 50g deionized water under 100W ultrasonic power, the ultrasonic process lasts 10min, disperse The concentration of graphene oxide in the solution was 0.05% by mass.

[0077]Preparation of nanocellulose crystal (CNC) dispersion: 0.025g of nanocellulose crystal powder (diameter 10nm, length 200nm) was dispersed in 50g of water, and the concentration of nanocellulose crystal in the dispersion was 0.05% by mass.

[0078] The above-mentioned GO dispersion liquid and CNC dispersion liquid were mixed according to the mass ratio of 98:2 to obtain a mixed dispersion liquid.

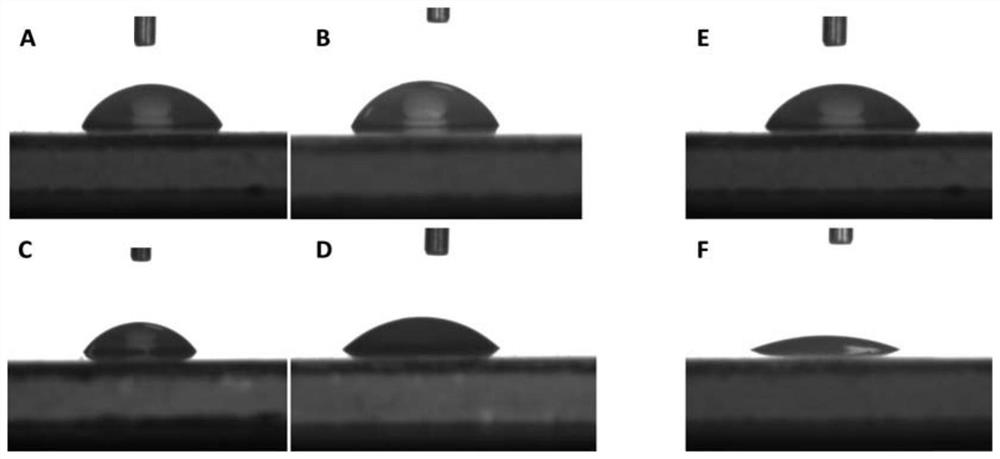

[0079] The polyethersulfone (PES) bacterial filter membrane is selected as the base membrane, the membrane pore size is 0.45 μm, and the membrane diameter is 9 mm. The base film was soaked in 0.1% by mass polyvinylpyrrolidone (PVP) aqueous solution for 1 min and then dried to ...

Embodiment 2

[0082] Preparation of graphene oxide (GO) dispersion: Disperse 0.025g single-layer graphene oxide (thickness is about 1nm, size 2-10μm) in 50g deionized water under 100W ultrasonic power, the ultrasonic process lasts 10min, disperse The concentration of graphene oxide in the solution was 0.05% by mass.

[0083] Preparation of nanocellulose crystal (CNC) dispersion: 0.025g of nanocellulose crystal powder (diameter 10nm, length 200nm) was dispersed in 50g of water, and the concentration of nanocellulose crystal in the dispersion was 0.05% by mass.

[0084] The above-mentioned GO dispersion liquid and CNC dispersion liquid were mixed according to the mass ratio of 95:5 to obtain a mixed dispersion liquid.

[0085] The polyethersulfone (PES) bacterial filter membrane is selected as the base membrane, the membrane pore size is 0.45 μm, and the membrane diameter is 9 mm. The base film was soaked in 0.1% by mass polyvinylpyrrolidone (PVP) aqueous solution for 1 min and then dried to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com