Auxiliary tool for installing synchronous wheel on servo motor

An auxiliary tool, servo motor technology, applied in the direction of electromechanical devices, manufacturing tools, manufacturing motor generators, etc., can solve the problems of motor damage, motor casing crushing, etc., to prevent crushing, good buffering, and reduce pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

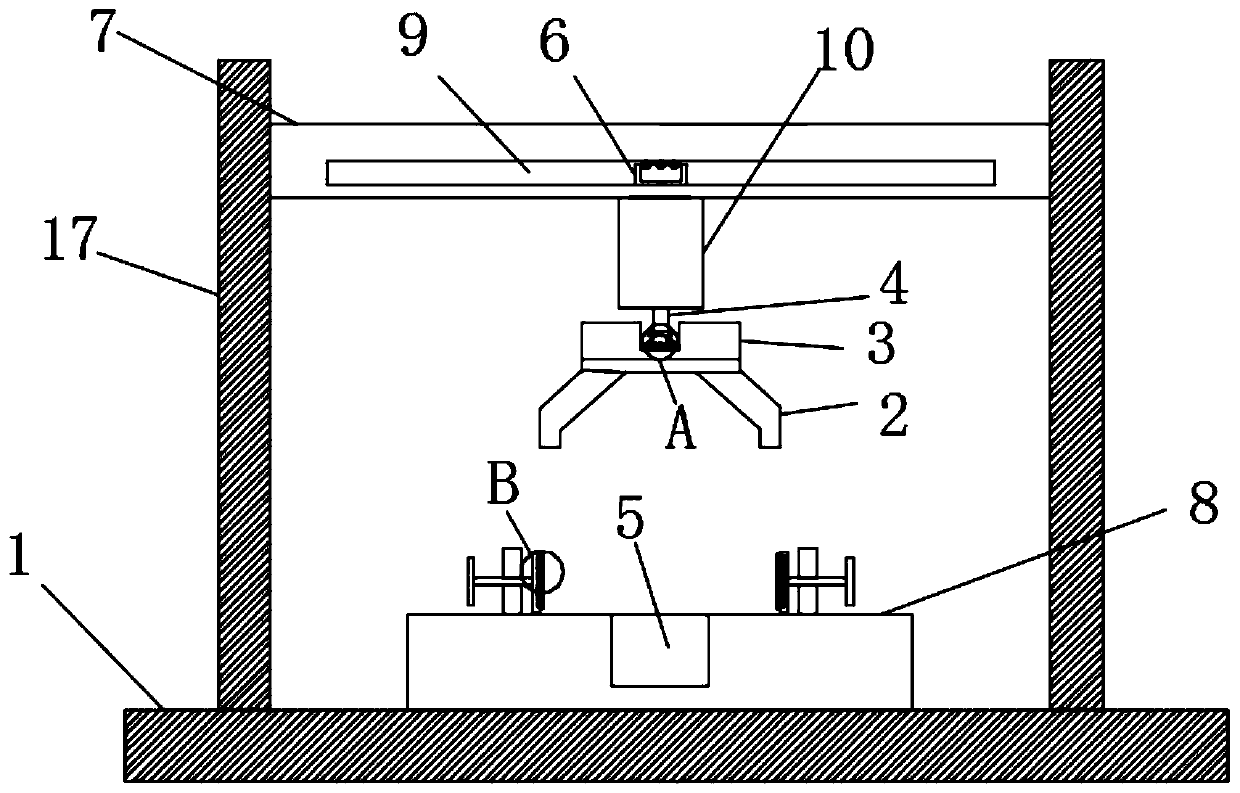

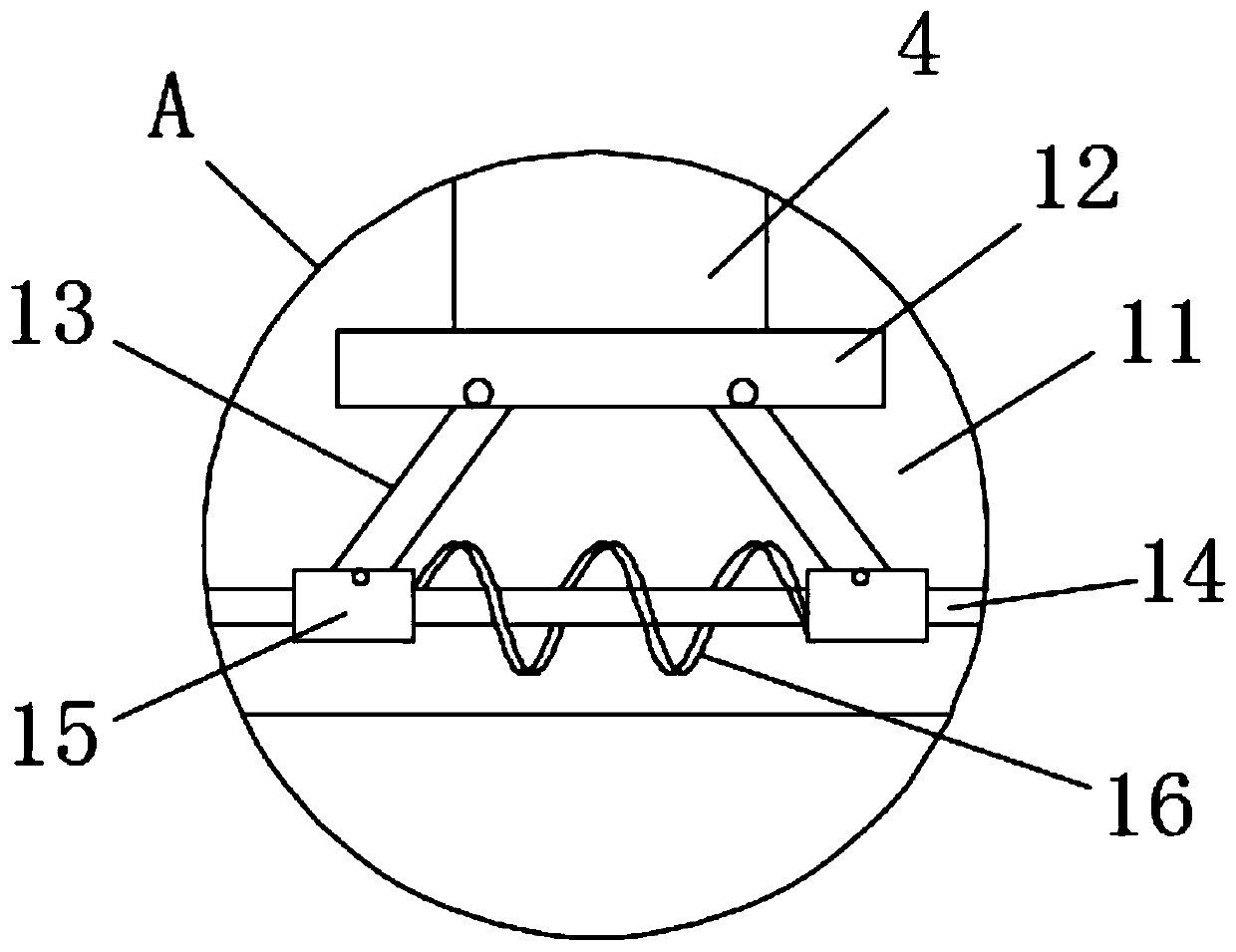

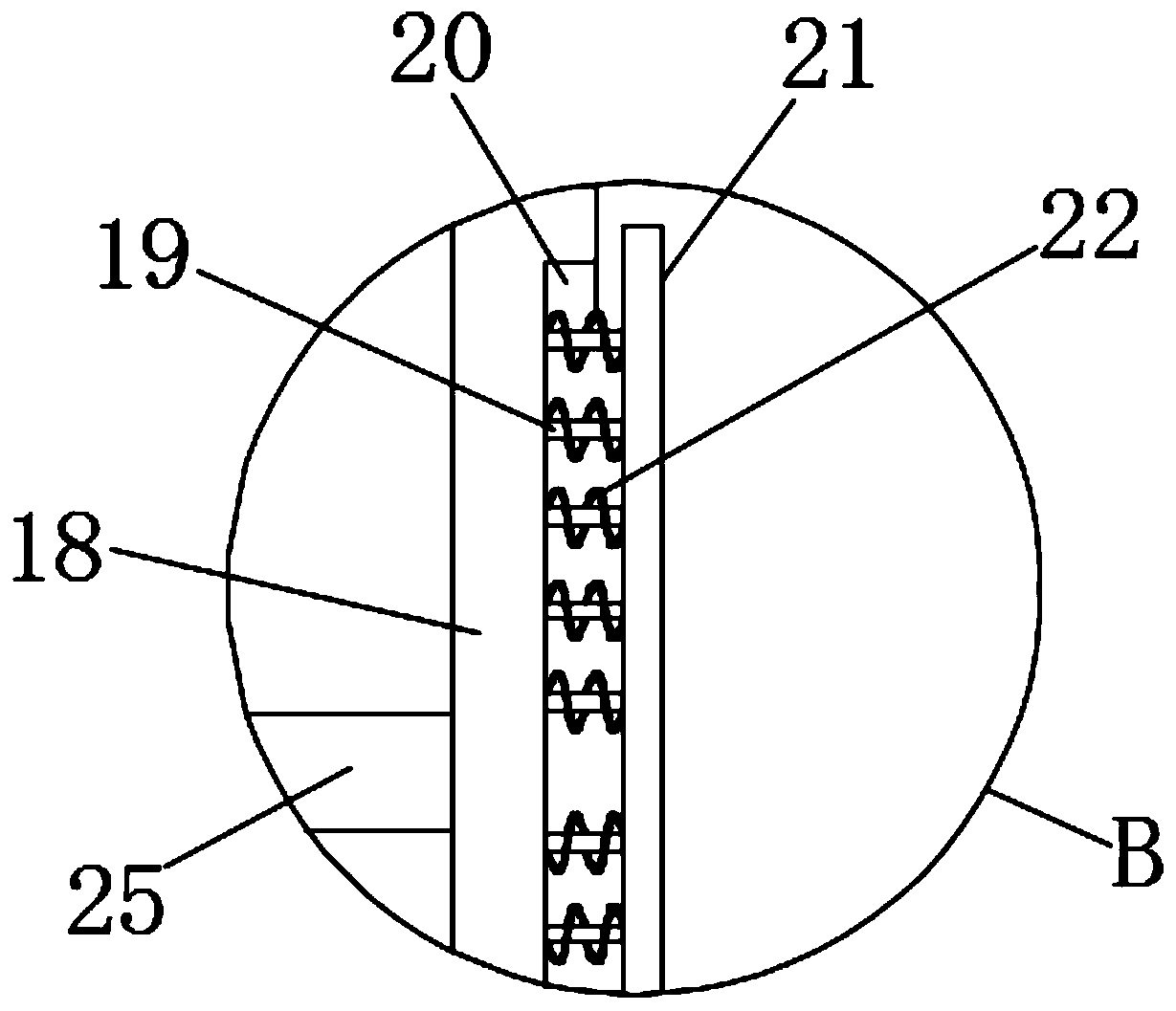

[0027] refer to Figure 1-4 , an auxiliary tool for installing synchronous wheels for servo motors, including a base 1, a magnetic column 5 is fixedly installed at the center of the upper end surface of a placement table 8, and the magnetic column 5 has a guiding effect on the placement of the motor, and has a good effect on the motor Adsorption effect, the upper side wall of the base 1 is fixedly connected with a placement table 8, the upper side wall of the base 1 is connected with a mounting plate 7 through a support device, the support device includes two support plates 17, and each support plate 17 is fixedly connected On the base 1 , each support plate 17 is fixedly connected with the installation plate 7 , and the support plates 17 have a supporting effect on the installation plate 7 .

[0028] There is a sliding cavity 9 in the mounting plate 7, and the inner wall of the sliding cavity 9 is connected with a moving plate 10 through a sliding device. The sliding device i...

Embodiment 2

[0033] Embodiment 2 differs from Embodiment 1 in that it is an auxiliary tool for installing synchronous wheels for servo motors. Placement has a guiding effect and has a good adsorption effect on the motor. The upper side wall of the base 1 is fixedly connected with a placement table 8, and the upper side wall of the base 1 is connected with a mounting plate 7 through a supporting device. The supporting device includes two supporting devices. Plates 17 , each support plate 17 is fixedly connected to the base 1 , each support plate 17 is fixedly connected with the installation plate 7 , and the support plates 17 have a supporting effect on the installation plate 7 .

[0034] There is a sliding cavity 9 in the mounting plate 7, and the inner wall of the sliding cavity 9 is connected with a moving plate 10 through a sliding device. The sliding device includes a moving block 6, and one end of the moving block 6 is fixedly connected to the moving plate 10, and the moving block 6 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com