Anti-puncturing self-repairing tire upgrade rubber material

A self-repairing and sizing technology, applied in the direction of adhesives, other rubber adhesives, adhesive types, etc., can solve the problems of poor bonding effect, impact, and inability to fully repair perforations, etc., to achieve good repairing effect, Strong adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

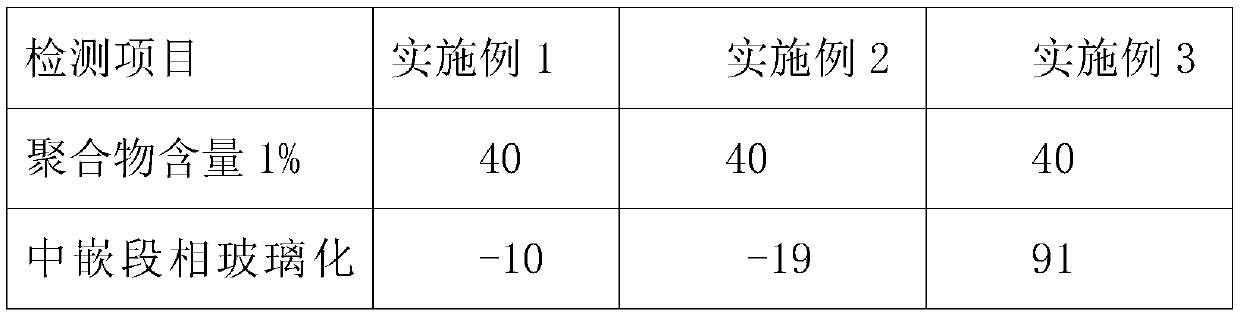

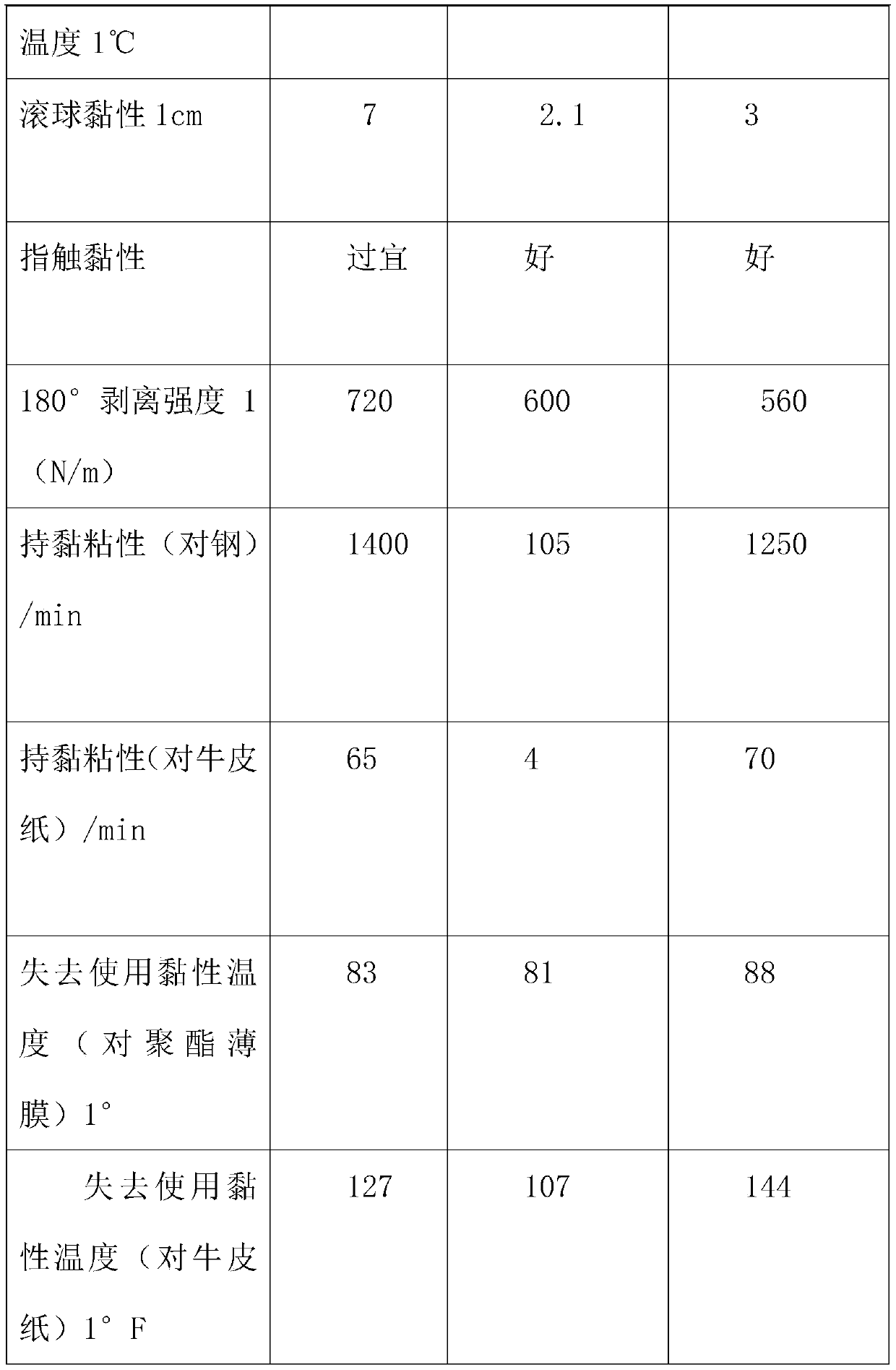

Embodiment 1

[0010] An anti-puncture self-repairing tire upgrading compound comprises the following raw materials in parts by weight: 100 parts of linear thermopolymerizable rubber, 123 parts of hydrogenated polyterpene resin, and 27 parts of butene polymer.

Embodiment 2

[0012] An anti-puncture self-repairing tire upgrading compound comprises the following raw materials in parts by weight: 100 parts of linear thermopolymerizable rubber, 104 parts of hydrogenated polyterpene resin, and 46 parts of butene polymer.

Embodiment 3

[0014] An anti-puncture self-repairing tire upgrading compound comprises the following raw materials in parts by weight: 100 parts of linear thermopolymerizable rubber, 91 parts of hydrogenated polyterpene resin, and 24 parts of butene polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com