A method for preparing flexible conductive composite materials by adjusting graphene alignment by magnetic field

A flexible conductive, composite material technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of easy stacking, agglomeration, uneven distribution, etc., to achieve large-scale production, low requirements for preparation conditions, material Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

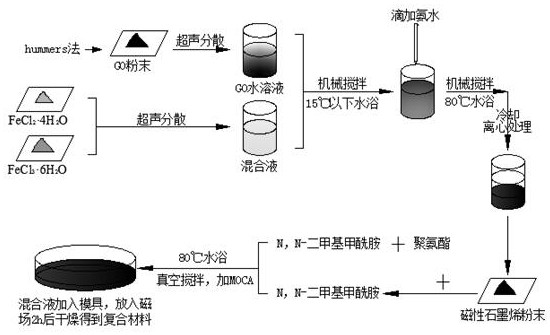

[0026] Such as figure 1 As shown, the method for preparing a flexible conductive composite material by adjusting the arrangement of graphene through a magnetic field, the specific steps are as follows:

[0027] Step 1. Prepare graphene oxide, ferrous chloride tetrahydrate, and ferric chloride hexahydrate aqueous solutions respectively, and then blend them. Keep the temperature below 15°C and vacuum mechanically stir for 10 minutes at a speed of 500r / min. Add ammonia water dropwise to adjust the pH value 10, mechanically stirred in a water bath at a temperature of 80°C (rotation speed: 500r / min) for 15min, and the mixture was cooled (cooled at 25°C) and then centrifuged to separate the precipitated substance from the lower layer and rinse it with deionized water until medium After drying at 40°C for 12 hours, magnetic graphene powder was prepared; the graphene oxide aqueous solution concentration was 1 / 2mg / mL; in step 1, the mass ratio of ferrous chloride tetrahydrate and ferri...

Embodiment 2

[0034] Such as figure 1 As shown, the method for preparing a flexible conductive composite material by adjusting the arrangement of graphene through a magnetic field, the specific steps are as follows:

[0035] Step 1. Prepare graphene oxide, ferrous chloride tetrahydrate, and ferric chloride hexahydrate aqueous solutions respectively, and then blend them. Keep the temperature below 15°C and stir in vacuum for 15 minutes at a speed of 500 r / min. Add ammonia water dropwise to adjust the pH value 10, mechanically stirred in a water bath at a temperature of 70°C (rotation speed: 500r / min) for 10min, the mixture was cooled (cooled at 25°C), and then centrifuged to separate the precipitated substance from the lower layer and rinse it with deionized water until medium After drying at 60°C for 10 h, magnetic graphene powder was prepared; the graphene oxide aqueous solution concentration was 1 / 2mg / mL; in step 1, the mass ratio of ferrous chloride tetrahydrate to ferric chloride hexahy...

Embodiment 3

[0039] Such as figure 1 As shown, the method for preparing a flexible conductive composite material by adjusting the arrangement of graphene through a magnetic field, the specific steps are as follows:

[0040] Step 1. Prepare graphene oxide, ferrous chloride tetrahydrate, and ferric chloride hexahydrate aqueous solutions respectively, and then blend them, keep the temperature below 15°C and mechanically stir in vacuum for 12 minutes at a speed of 500r / min, add ammonia water dropwise to adjust the pH value 11, mechanically stirred in a water bath (rotating at 500r / min) at a temperature of 75°C for 20min, the mixture was cooled (cooled at 25°C) and then centrifuged to separate the precipitated substance from the lower layer and rinse it with deionized water until medium After drying at 50°C for 11 hours, magnetic graphene powder was prepared; the graphene oxide aqueous solution concentration was 1 / 2mg / mL; in step 1, the mass ratio of ferrous chloride tetrahydrate and ferric chl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com