A kind of application method of binary copolymer containing benzene ring

A technology of binary copolymer and acid anhydride binary copolymer, which is applied in the directions of liquid carbonaceous fuel, fuel, fuel additive, etc. efficiency and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of diesel oil point depressant, is made up of binary copolymer containing benzene ring, the preparation method of described binary copolymer containing benzene ring is:

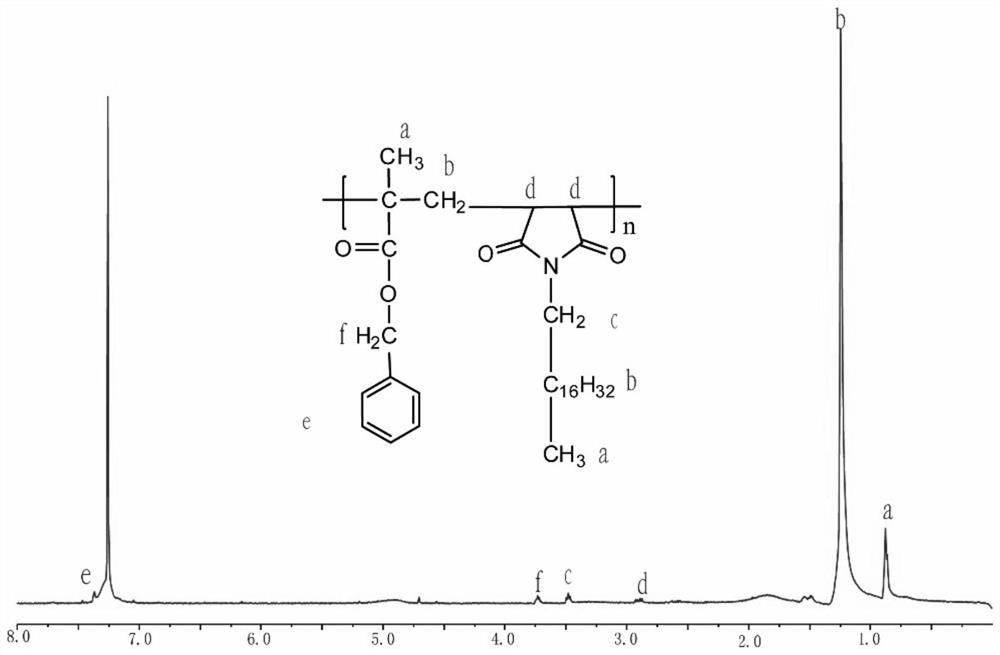

[0030] (1) Add 18.0g of benzyl methacrylate, 10.0g of maleic anhydride and 50mL of toluene to a three-necked flask equipped with a condenser, a temperature controller, a magnetic stirring device and a nitrogen gas inlet, and pass nitrogen into the three-necked flask first 2-3 minutes, vacuum 1-2 minutes, repeat three times to remove the air in the reaction system. Under nitrogen protection, the temperature of the system was slowly raised to 110° C., and 10 mL of toluene solution containing 0.224 g of benzoyl peroxide was added dropwise to the reactor (completely added within 30-45 minutes). After the reaction temperature was kept at 110°C for 8 hours of polymerization, the polymer was cooled to room temperature, excess ethanol was added dropwise to the reactant to produce a precipitate, the supe...

Embodiment 2

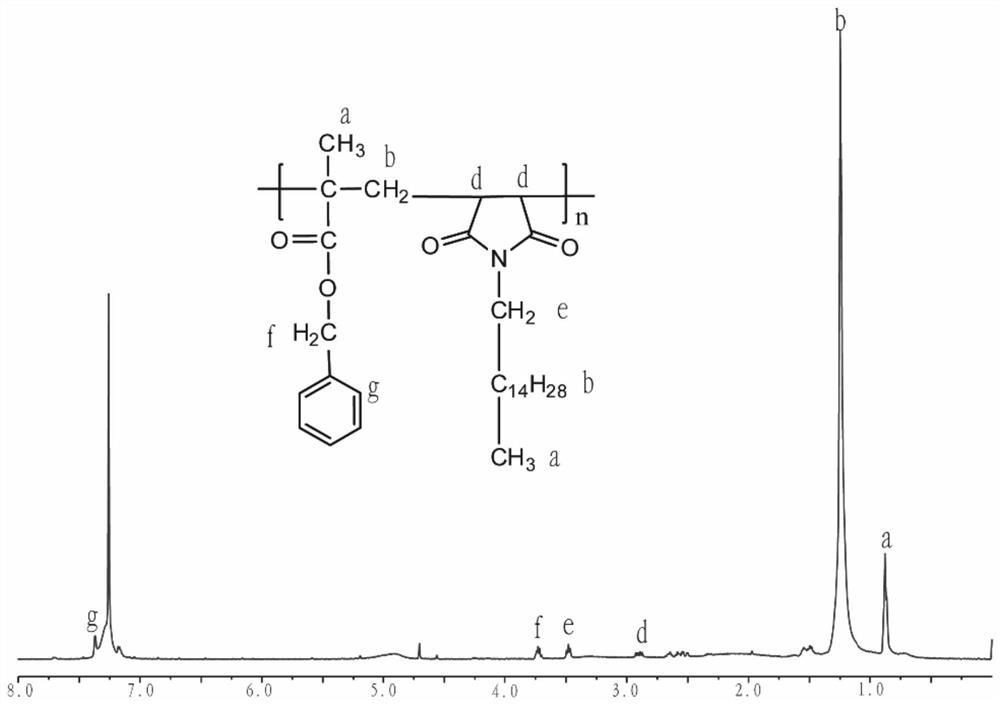

[0034] The difference from Example 1 is that in step (2), 11 g of octadecylamine and 0.104 g of catalyst p-toluenesulfonic acid are added instead of adding 9.8 g of hexadecylamine and 0.0944 g of catalyst p-toluenesulfonic acid. The molecular Mw of the polymer tested by GPC is 61860g / mol, Mn is 43510g / mol, and Mw / Mn is 1.422, and the product benzyl methacrylate-maleic anhydride-hexadecylamine is characterized by NMR as figure 2 shown.

Embodiment 3

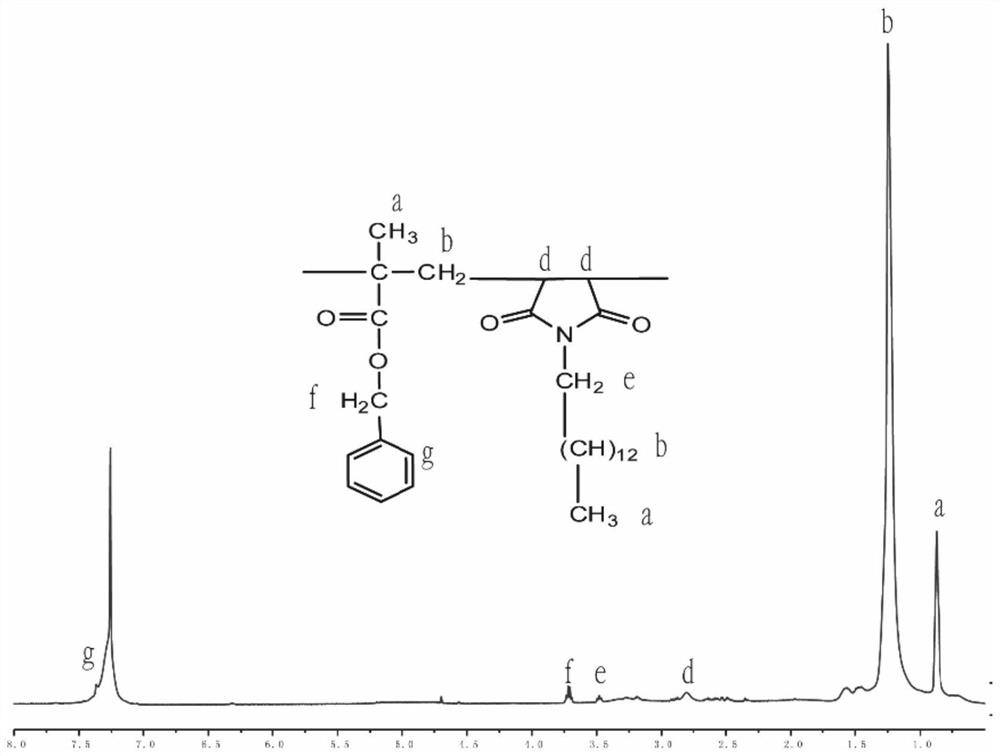

[0036] The difference from Example 1 is that in step (2), 11 g of octadecylamine and 0.104 g of catalyst p-toluenesulfonic acid were added instead of 8.7 g of tetradecylamine and 0.0856 g of catalyst p-toluenesulfonic acid. The molecular Mw of polymer tested by GPC is 63560g / mol, and Mn is 46240g / mol, and Mw / Mn is 1.375, and product benzyl methacrylate-maleic anhydride-tetradecylamine is carried out NMR characterization as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com