Nanorod-like vanadium tetrasulfide powder and preparation method and application thereof

A nanorod-shaped, vanadium tetrasulfide technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of large volume change and low conductivity, and achieve low reaction temperature, high specific capacity, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

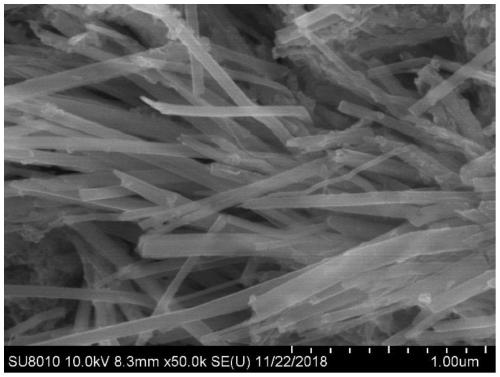

[0036] Take 5mmol of thioacetamide (TAA) and add it to 70mL of absolute ethanol, then stir it with magnetic force for 1h to make it completely dissolved; then add 1mmol of ammonium metavanadate under magnetic stirring, and continue stirring for 1h to make it completely dissolve; keep stirring Add 1mL of dilute hydrochloric acid, stir for 0.5h to form a transparent solution; the above stirring speed is 300r / min-400r / min, transfer the above-mentioned mixed solution to the polytetrafluoroethylene lining of a 100mL stainless steel autoclave, and seal the stainless steel autoclave React the kettle and put it into a blast drying oven for 24 hours at 180°C; after cooling to room temperature naturally, wash the product four times with anhydrous ethanol, four times with deionized water and dry it in vacuum for 12 hours , that is, nano-rod vanadium tetrasulfide powder. figure 1 It is the SEM picture of the nanorod-shaped vanadium tetrasulfide prepared in this embodiment. Confirmed that...

Embodiment 2

[0042] Take 4mmol of thioacetamide (TAA) and add it to 60mL of absolute ethanol, then stir it with magnetic force for 2h to make it completely dissolved; then add 0.5mmol of ammonium metavanadate under magnetic stirring, and continue stirring for 2h to make it completely dissolve; keep stirring Add 1mL of dilute hydrochloric acid, stir for 1h to form a transparent solution; the above stirring speed is 300r / min~400r / min, transfer the above-mentioned mixed solution to the polytetrafluoroethylene lining of a 100mL stainless steel autoclave, and seal the stainless steel autoclave React the kettle and put it into a blast drying oven for 23 hours at 190°C; after cooling to room temperature naturally, wash the product four times with anhydrous ethanol, four times with deionized water and dry it in vacuum for 12 hours , that is, nano-rod vanadium tetrasulfide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge and discharge current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com