Preparation method of gadolinium oxysulfide powder and scintillation ceramics for X-ray detection

A technology of scintillation ceramics and gadolinium oxysulfide, which is applied in the direction of rare earth metal sulfides, can solve the problems of limited application, slow temperature rise, low production efficiency, etc., and achieve the effect of improving product quality, improving yield rate, and facilitating manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of scintillation ceramics is:

[0050] Step 1: First weigh high-purity Gd 2 o 3 、Pr 6 o 11 , CeO 2 After mixing and ball milling, add elemental sulfur and high-purity flux soda ash and mix evenly in proportion to form raw materials;

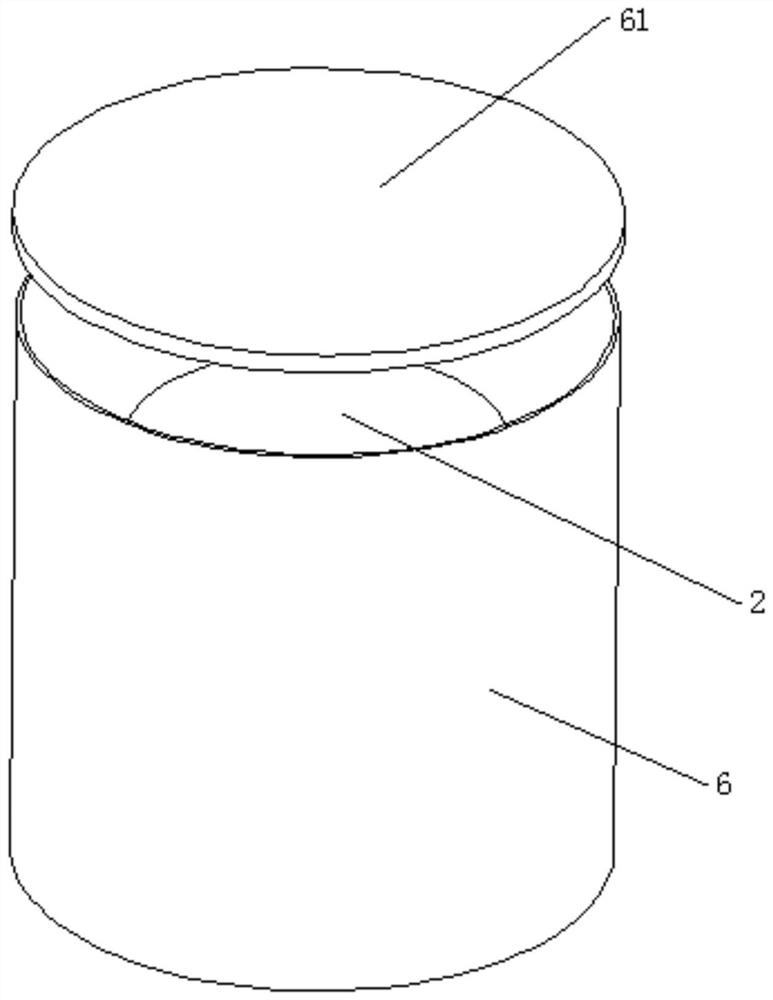

[0051] Step 2: Add activated carbon granules and powder to the reaction ceramic crucible 6, after laying flat in the reaction ceramic crucible 6, put the backing plate 5 for charging, place the mold tube 2 on the backing plate 5, install the mold tube 2 Put in the raw material, press the raw material through the pressing block 21, fix the raw material into shape, take off the mold tube 2, add a cover plate 61 on the reaction ceramic crucible 6, try to achieve a sealed state, and heat up to 800 in the muffle furnace. -1300℃, keep warm for 2-7 hours;

[0052] Step 2: After the calcined powder is taken out, put it in a plastic bucket and add pure water. After several times of pure water washing, the measured condu...

Embodiment 1

[0056] Embodiment 1: being different from embodiment is, weigh 200gD50 in the high-purity Gd of 2-3um 2 o 3 , adding 0.15gPr 6 o 11 , 0.008gCeO 2 , (no need to add grinding balls) ball mill on a planetary ball mill for 2 hours, then add 100g of elemental sulfur and 100g of high-purity soda ash, and then ball mill for 4 hours. Put 100g of activated carbon particles and powder in the reaction ceramic crucible 6, spread it around the reaction ceramic crucible 6, then put into the alumina ceramic backing plate 5 of the charge, place the mold tube 2 on the backing plate 5, Pack the reacting material tightly in the mold, so that the protective and reducing atmosphere can fully contact with the material. After heating up to 1100°C, keep it warm for 5 hours and then cool naturally. The cooled material is lumpy. After taking it out, soak it in 50°C non-salt water for 1-2 hours. There will be no lumpy particles under the agitation of the stirrer, and then filter it with a centrifuge...

Embodiment 2

[0057] Embodiment 2: weighing 200gD50 in the high-purity Gd of 2-3um 2 o 3 , adding 0.15gPr 6 o 11 , 0.008gCeO 2 , (no need to add grinding balls) ball mill on a planetary ball mill for 2 hours, then add 90g of elemental sulfur and 90g of high-purity soda ash, and then ball mill for 4 hours. Put 100g of activated carbon particles and powder in the reaction ceramic crucible 6, spread it around the reaction ceramic crucible 6, then put into the alumina ceramic backing plate 5 of the charge, place the mold tube 2 on the backing plate 5, Tightly pack the reacting material in the mold tube 2, so that the protective and reducing atmosphere can fully contact the material, heat it up to 1100°C, keep it warm for 5 hours, and then cool it down naturally. The cooled material is lumpy, take it out and soak it in 50°C non-salt water for 1-2 hours, and there will be no lumpy particles under the agitation of the stirrer, then filter it with a high-speed centrifuge, and continue to add 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com