Manufacturing process of light guide fiber illuminatormodule lamp

A technology of light guide fiber and manufacturing process, which is applied in the field of manufacturing process of light guide fiber emitter module lamps, can solve the problems of easy failure of light guide fiber fixation, deflection and deformation of pressure spring, troublesome installation and operation, etc., so as to avoid insertion The effect of fixing and fixing failure, avoiding the skew of compression spring, and making production and assembly easy and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A manufacturing process of a light guide fiber emitter module lamp, comprising the following steps:

[0041] Step 1: Assemble the shell, light source board and lock core into a module;

[0042] Step 2: Insert the light guide fiber into the corresponding lock core, and assemble it into a modular light.

[0043] The structure of the module lamp is as follows:

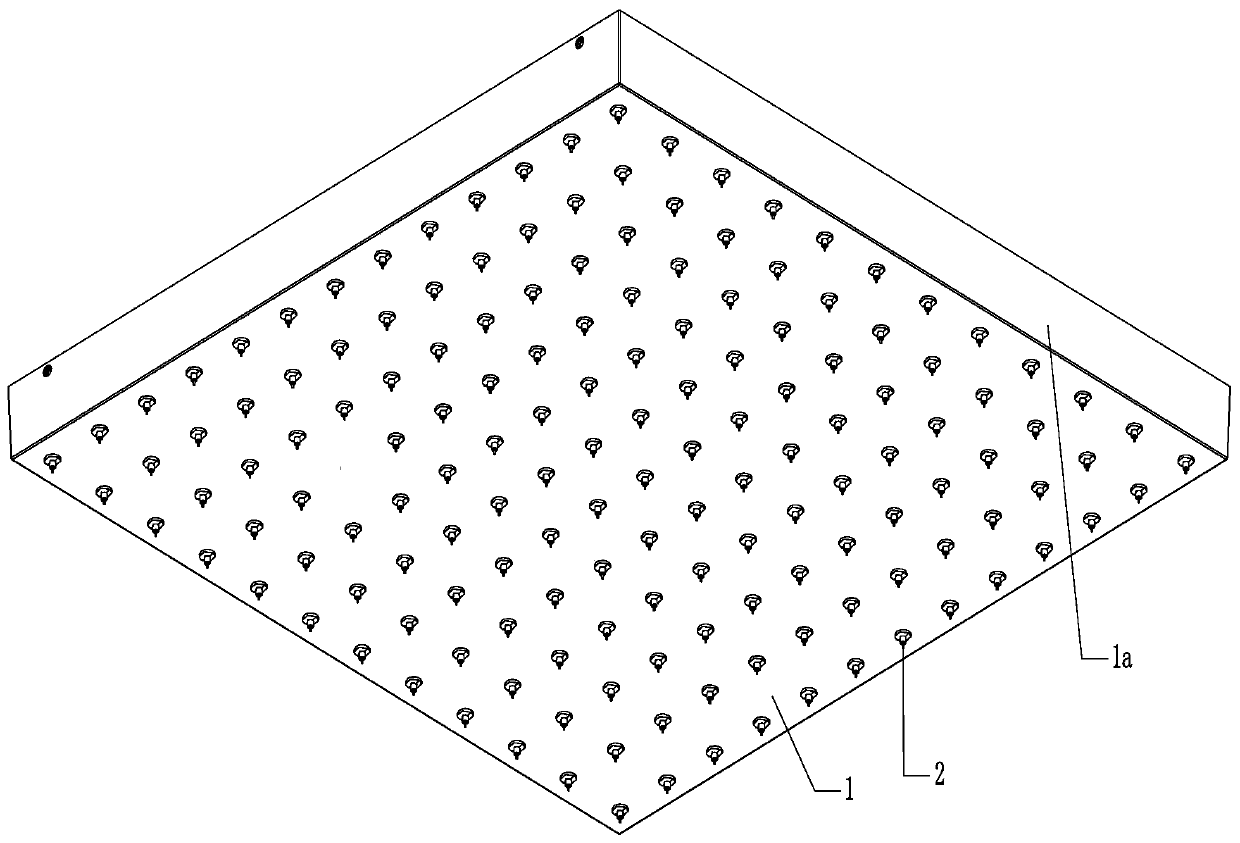

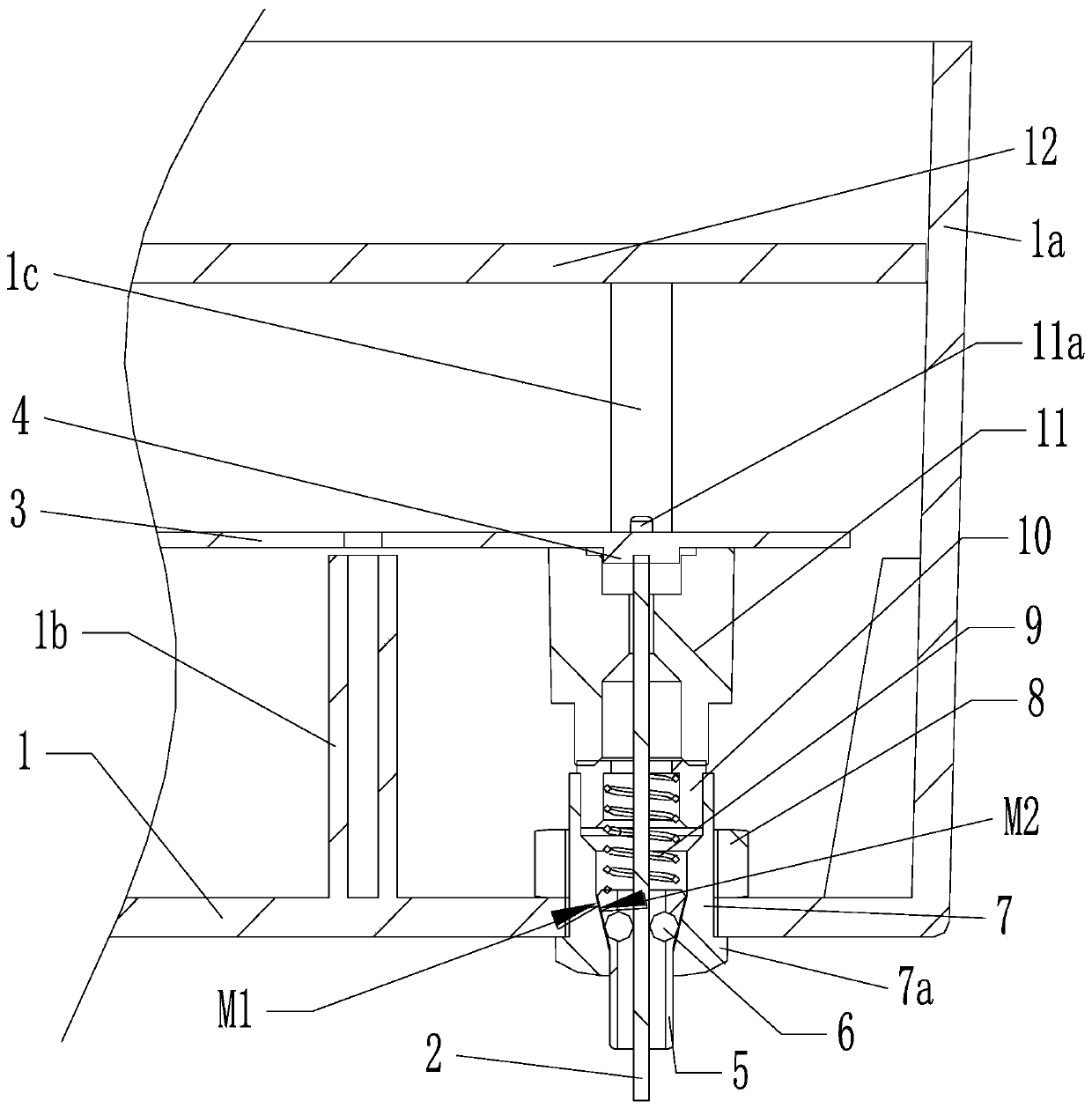

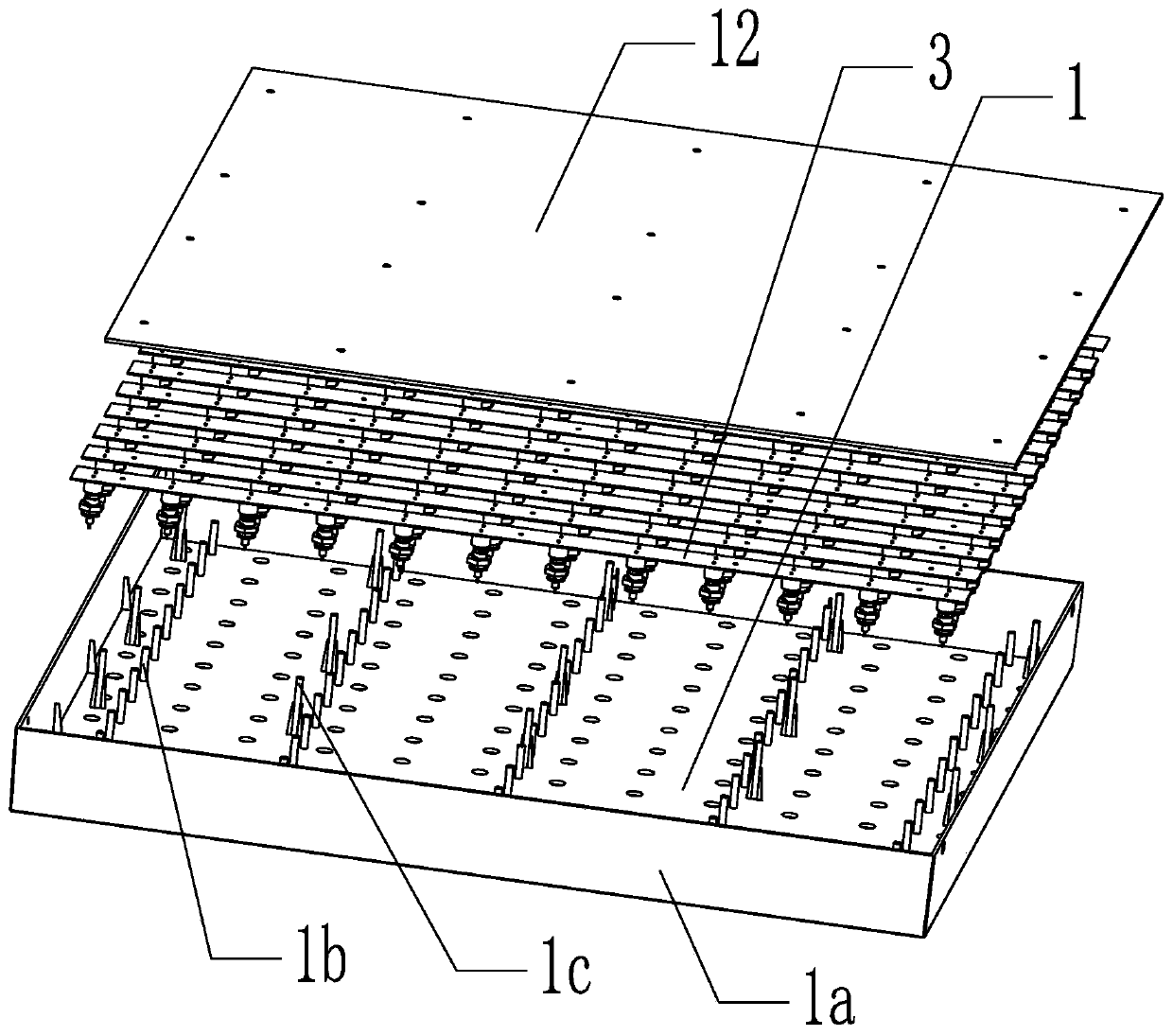

[0044] Such as figure 1 and image 3 As shown, it includes a casing 1 and at least one light source board 3, at least one installation hole 1d is opened on the casing 1, and light sources 4 corresponding to the installation holes 1d are provided on the light source board 3. The shape of the housing 1 is not limited, and may be rectangular, circular or other shapes. The edge of the shell 1 extends inward to form a shroud 1a, so that the shell 1 is in the shape of a box with an opening, and the shell 1 in this embodiment is in a square shape. The inner wall of the housing 1 protrudes to form at least one mounti...

Embodiment 2

[0052] Such as Figure 4 and Figure 5 As shown, in this embodiment, the first locking frame 11 extends toward one end of the conduit 10 to form a tube portion 11 b that accommodates the conduit 10 and the inner end of the first locking cup 7 . The shell 1 is in the shape of a strip. Other technical features of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0054] Such as Figure 6 and Figure 7 As shown, the positioning assembly includes a mounting tube 1e formed by a protrusion on the inner wall of the housing 1, and a second locking cup 13 and a second locking frame 14 are installed in the mounting tube 1e, and the second locking cup 13 Located between the second locking frame 14 and the inner wall of the housing 1 , the first tapered surface M1 is located in the second locking cup 13 . The inner end of the second locking frame 14 is in contact with the light source board 3, and at the end of the second locking frame 14 facing the second locking cup 13, a guide hole with a large outside and a small inside is provided. The compression spring 9 snapped into the guide hole. On the end of the second locking frame 14 facing the light source board 3 , there is a through hole through the guide hole to make way for the light guide fiber 2 , and the inner end of the through hole is thickened to make way for the light source 4 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com