Dual-power-source vehicle-mounted tunnel lamp cleaning system

A dual power source and cleaning system technology, applied in road cleaning, cleaning methods, construction, etc., can solve the problems of easy accumulation of solid particles, poor low-speed stability, and influence on safe traffic, etc., to achieve improved cleaning efficiency, stable and uniform driving, and easy The effect of load control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

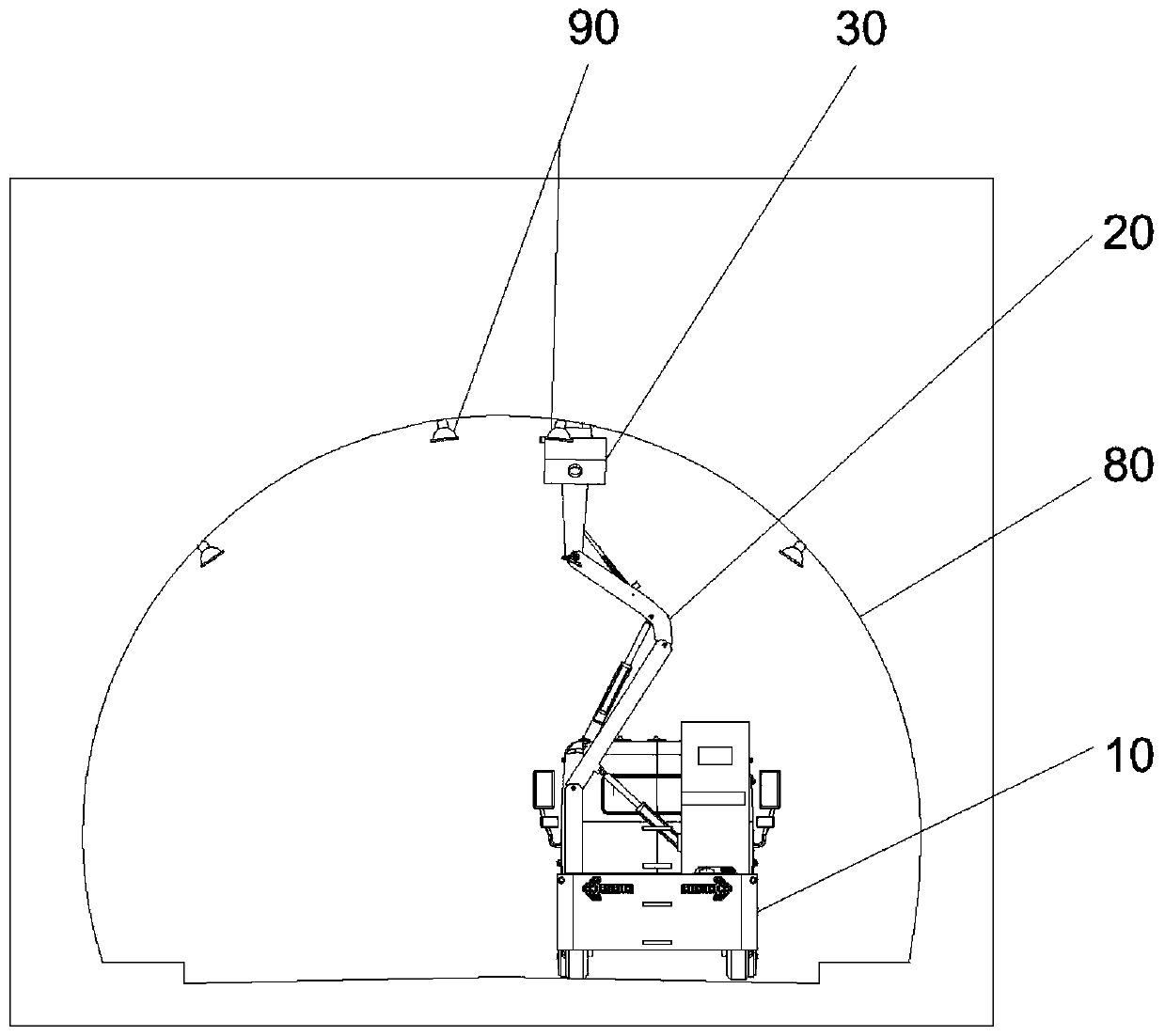

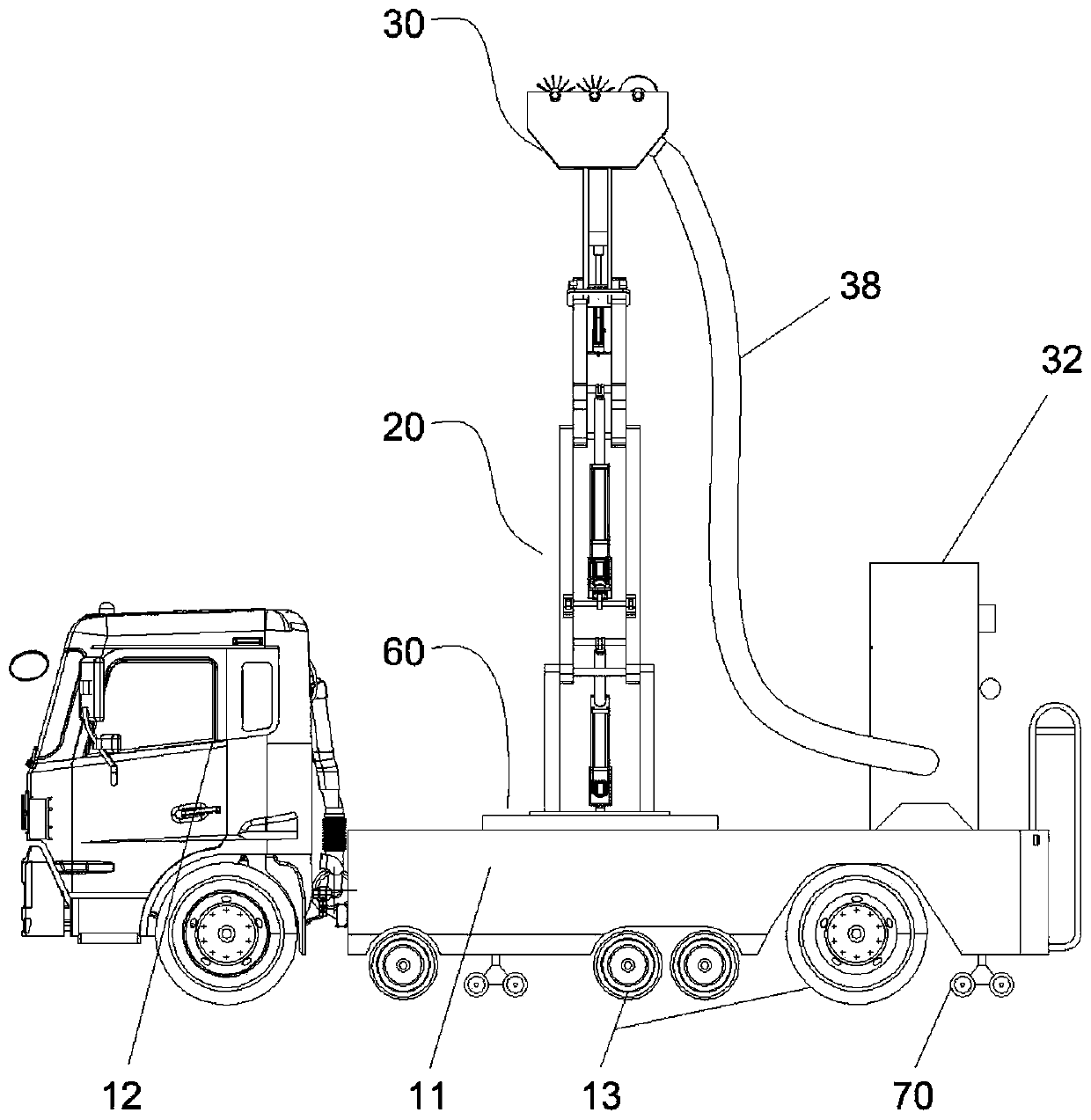

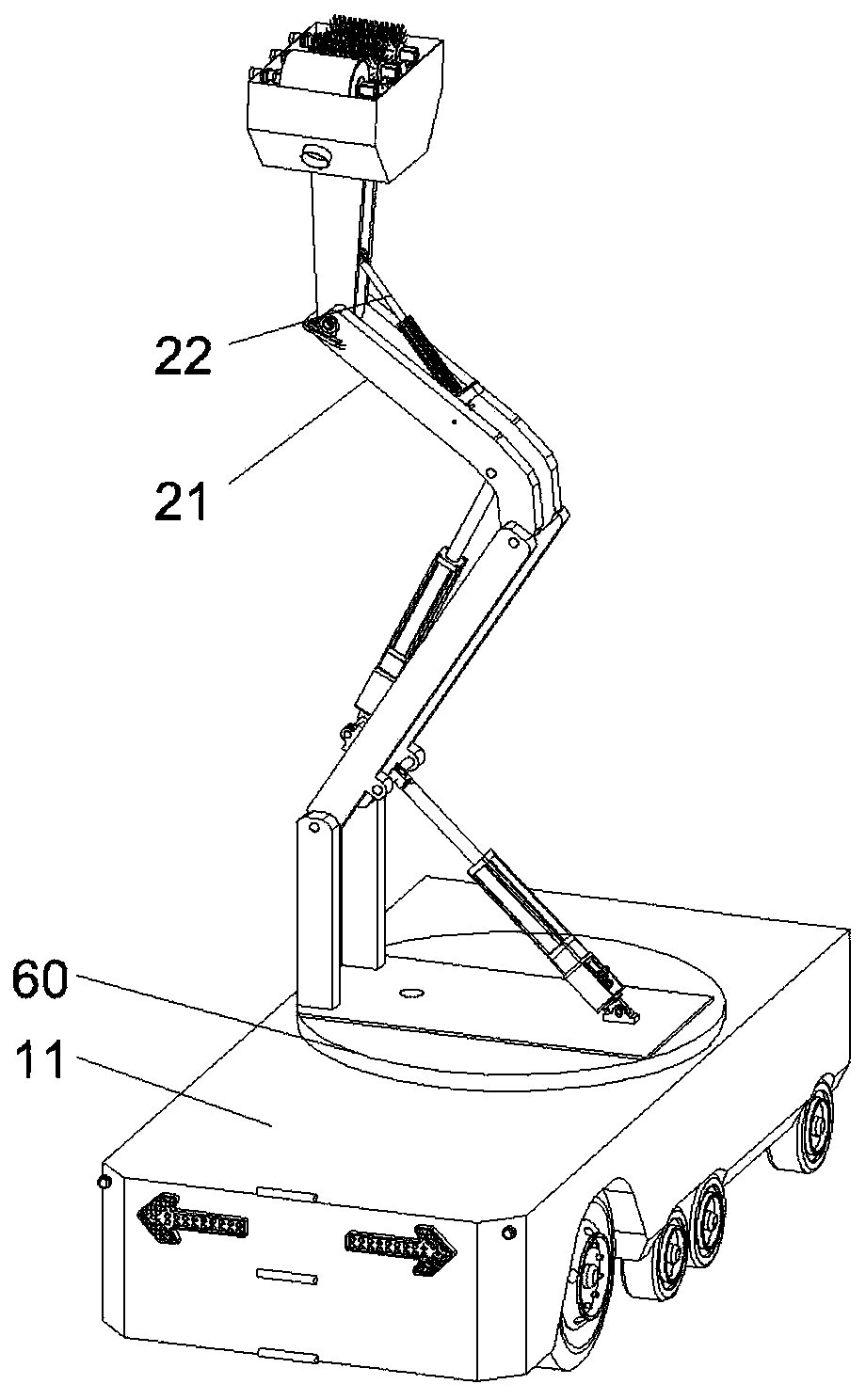

[0034] figure 1 It is a structural schematic diagram of the cleaning state of the present invention; figure 2 It is a schematic diagram of the overall structure of the present invention; image 3 It is a schematic diagram of the structure of the lifting platform; Figure 4 It is a schematic diagram of the structure of the cleaning device (with outer cover); Figure 5 It is a schematic diagram of the top view structure of the outer cover; Image 6 It is a schematic diagram of the sectional structure of the outer cover; Figure 7 It is a schematic diagram of the structure of the cleaning device (without the outer cover); Figure 8 Schematic diagram of the installation structure for the brush assembly; Figure 9 It is a structural schematic diagram of the brush assembly and the sponge roller; Figure 10 It is a schematic diagram of the switching structure of dual power sources;

[0035] As shown in the figure: the dual power source vehicle-mounted tunnel lamp cleaning sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com