All-terrain inspection robot

An inspection robot and all-terrain technology, which is applied to motor vehicles, crawler vehicles, transportation and packaging, etc., can solve problems such as large frictional resistance, inability to overcome obstacles on the stepped ground of crawler structure, and limitation of inspection operation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

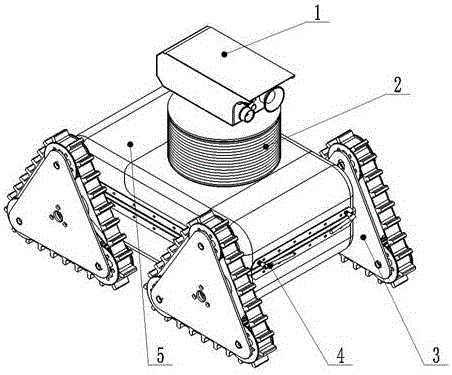

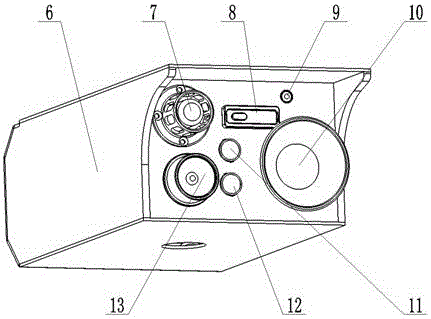

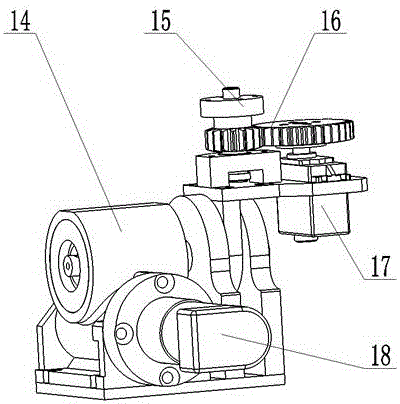

[0020] The all-terrain inspection robot of the present invention, such as figure 1 As shown, it consists of a robot detection device 1, a gimbal 2, a triangular drive train 3, a wireless antenna 4, and a robot body 5; as figure 2 As shown, the robot detection device includes a protective sealing cover 6, a long-distance temperature sensor 7, a laser rangefinder 8, an indicator light 9, a high-definition visible light camera 10, a high-sensitivity sound pickup probe 11, an infrared probe 12, and a torch 13; image 3 As shown, the platform is composed of a worm gear reducer 14, a flange 15 connected with a detection device, an acceleration gear set 16, a rotating motor 17, an elevation motor 18, and the like. In the all-terrain inspection robot of the present invention, the control device is composed of electrical components, a driver, a cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com