Method and device for determining the consumption of electrode material during the operation of an electric furnace

A technology of electrode materials and transportation devices, which is applied in the direction of electric heating devices, transportation and packaging, furnace control devices, etc., can solve the problems of limitation, high cost of materials and personnel, and inability to obtain electrode consumption evaluation, etc., to achieve reliable consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

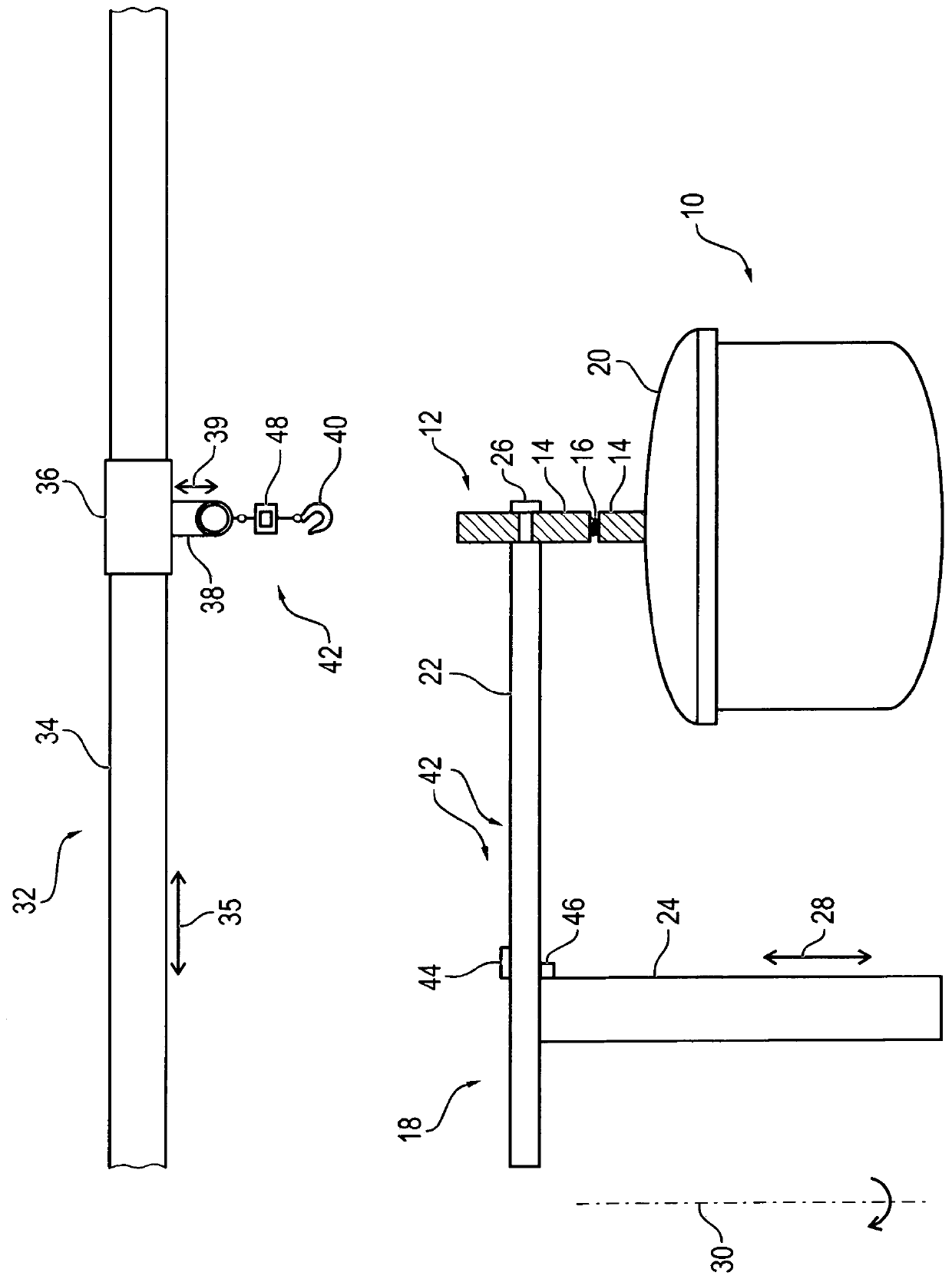

[0045] figure 1 Illustrated is a system comprising an electric arc furnace 10 which receives as raw material eg steel scrap and optionally further additives, in which the raw material is melted by the thermal energy of an electric arc emitted in the electric arc furnace 10 .

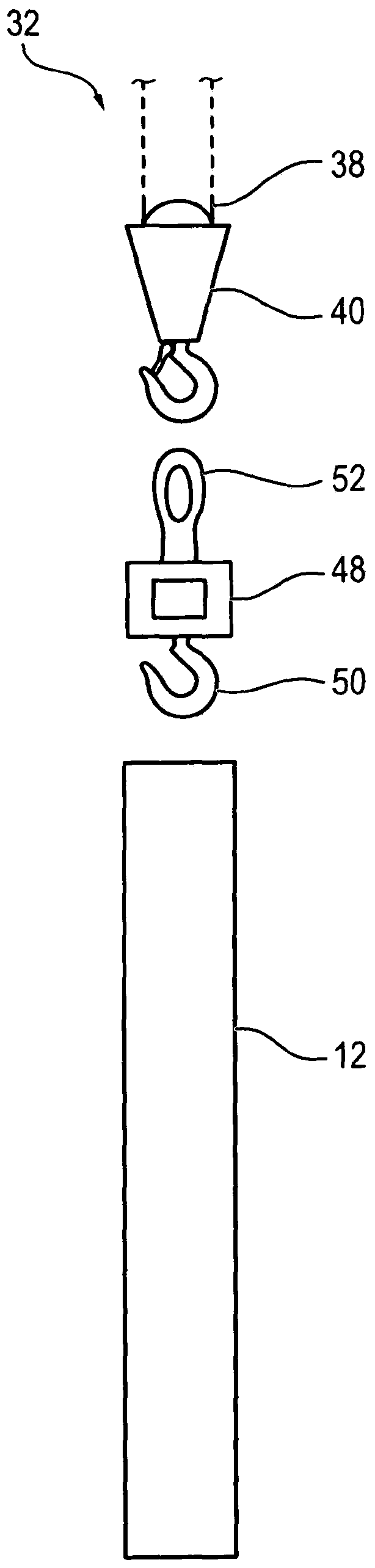

[0046] To start the arc, the system has: a bottom electrode ( figure 1 not shown in ), the bottom electrode is arranged in the electric arc furnace 10 and is in direct electrical contact with the raw material of the electric arc furnace 10; and the electrode column 12 is composed of a plurality of elongated graphite electrodes 14, the plurality of Elongated graphite electrodes 14 are screwed together via threaded joints 16 at their respective longitudinal ends. In practice, a plurality, in particular three, of electrode columns 12 arranged parallel to each other can be used, for clarity only in figure 1 One electrode column 12 is shown in , in particular the bottom electrode is omitted.

[0047] Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com