A premixing device for rubber powder modified asphalt

A technology of modified asphalt and rubber powder, which is applied in the field of premixing devices for rubber powder modified asphalt, which can solve the problems of not being able to screen, cannot be distinguished, and rubber powder particles should not be too large, so as to achieve a uniform mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

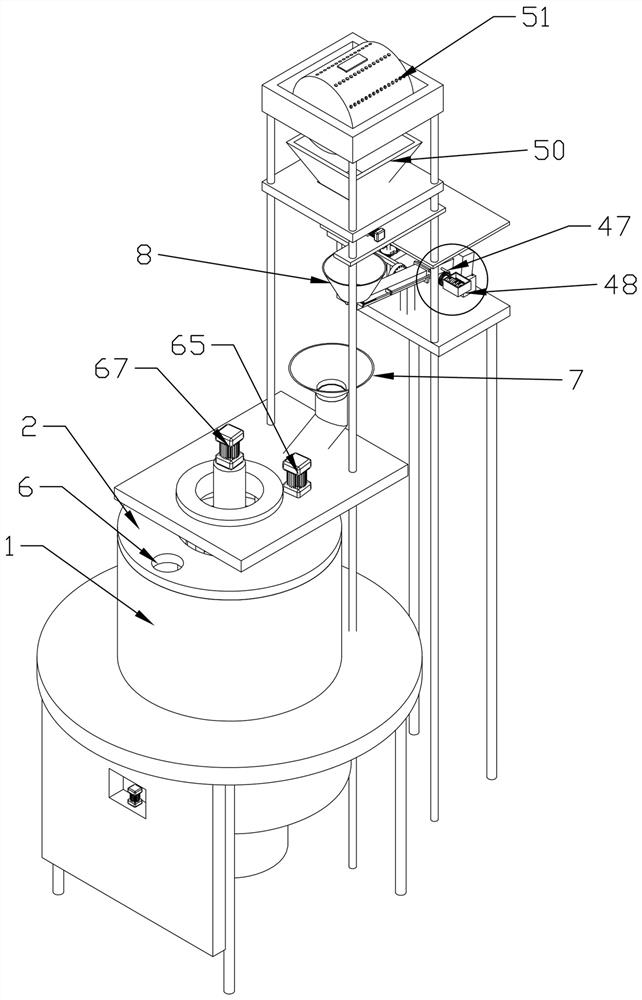

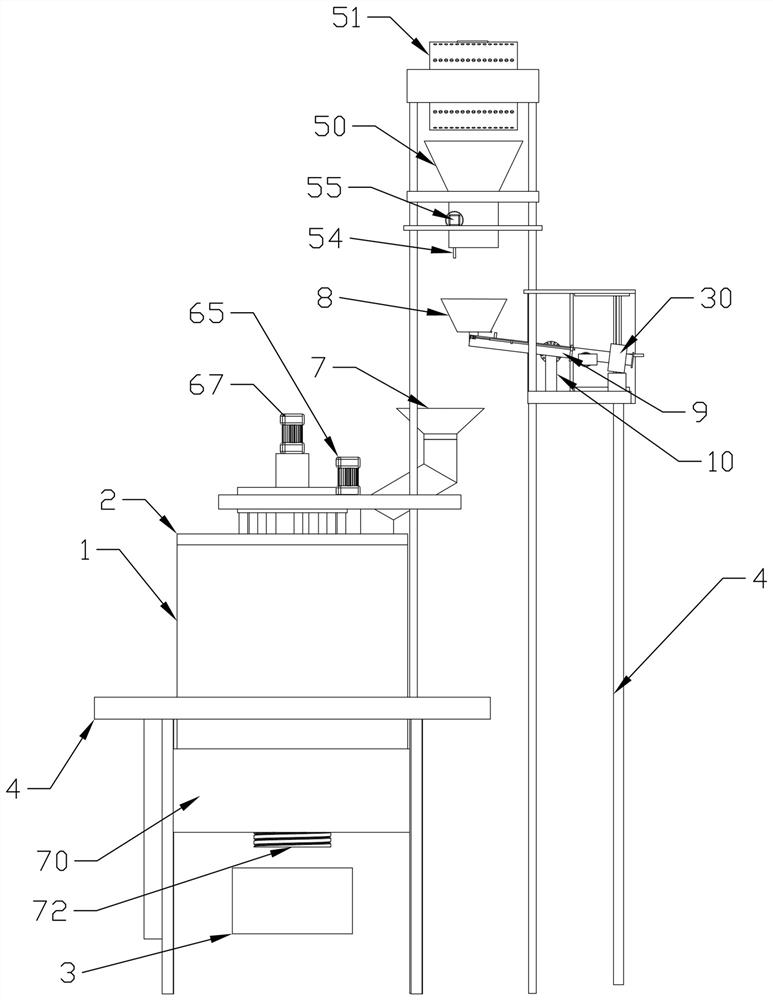

Embodiment 1

[0041] Embodiment 1 includes a barrel-shaped casing 1 for mixing asphalt and rubber powder. Inside the casing 1 is a mixture of asphalt and rubber powder. The upper end of the casing 1 is sealed with a shell cover 2. The main part of the shell cover 2 The function is to prevent the asphalt inside from splashing when stirring, and to keep warm. There is an infusion device for pouring rubber powder on the top of the shell 1, and a collection bucket 3 for receiving pre-mixed asphalt under the shell 1. , the pre-mixed rubber asphalt finished product enters the collection bucket 3, and the bracket 4 used to support the whole device. The housing 1 is provided with a stirring device, which needs to be poured into the asphalt first, heated and stirred, and then in the process of stirring Add rubber powder, place the entire bracket 4 on the ground, fix the shell 1 on the bracket 4, the shape of the bracket 4 is not limited to the shape shown in the figure, its function is to fix the who...

Embodiment 2

[0049] Embodiment 2, on the basis of Embodiment 1, the middle of the housing 1 has a hollow stirring column 60 that coincides with the axis of the housing 1, and the outer ring of the stirring column 60 has a helical stirring wheel 61, The outer ring of the stirring wheel 61 contacts the inside of the housing 1, and a crushing column 63 is fitted in the middle of the stirring column 60, and the outer ring of the crushing column 63 has a plurality of leaf-shaped crushing leaves 64. 64 can break up the asphalt-wrapped rubber powder group. The upper end of the stirring column 60 extends out of the stirring port 5, is not connected with the housing 1, and is fixed on the support 4. When working, it rotates by itself, and is connected with the The stirring motor 65 that is fixed on the support 4 is connected, and when being connected with the stirring motor 65, the stirring column 60 is also connected with a heater, and the cylindrical wall of the stirring column 60 is provided with...

Embodiment 3

[0052] Embodiment 3, on the basis of Embodiment 2, several support columns 73 are connected to the upper end of the bucket of the stirring column 60, and through the plurality of support columns 73, the asphalt can enter the inside of the stirring column 60 when it is drawn upward by the stirring column 60, so The upper end of the support is fixedly connected with an auxiliary stirring ring 74, which makes the support more firm. The auxiliary stirring ring 74 is connected to the stirring motor 65, and the stirring motor 65 rotates the stirring ring to make the stirring column 60 rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com