A feeding device for high molecular polymer cementitious material in a mixing station

A high-molecular polymer and feeding device technology, which is applied in roads, constructions, road repairs, etc., can solve quantitative feeding problems and achieve the effect of avoiding residue and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

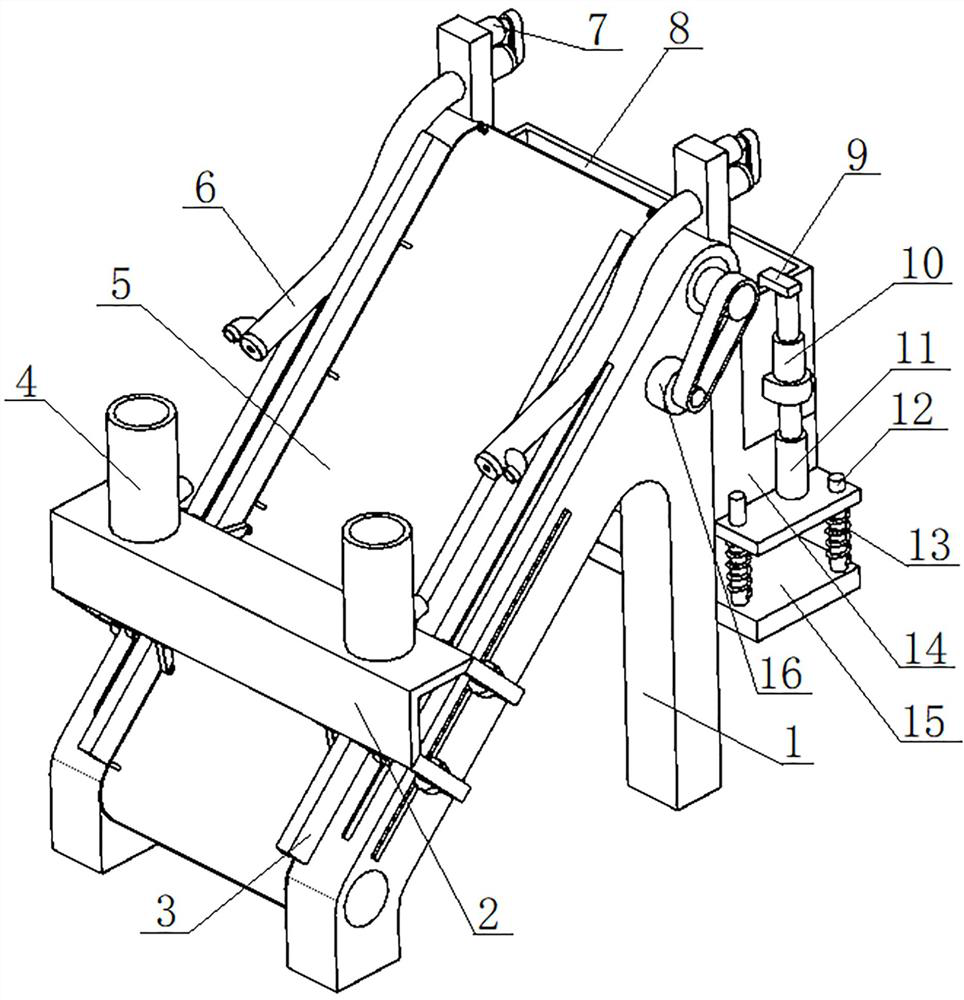

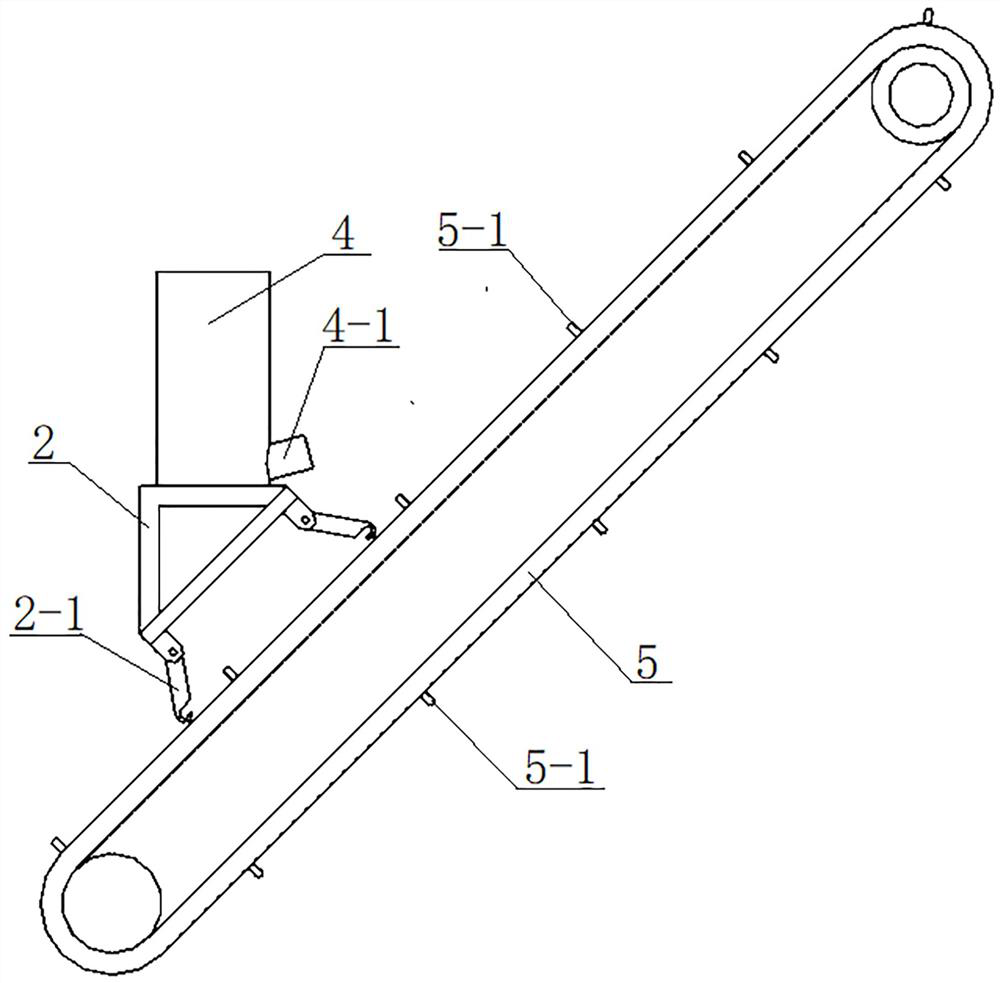

[0039] see figure 1, a feeding device for high molecular polymer cementitious material used in a mixing station, comprising a support 1, a transmission mechanism arranged obliquely on the support 1, a mobile car is arranged on the support 1 and above the transmission mechanism, the transmission mechanism and the mobile car can be Separate connection, the mobile car slides upwards or downwards along the bracket 1, the mobile car is equipped with a material barrel 4, and a liquid high molecular polymer is arranged in the material barrel 4;

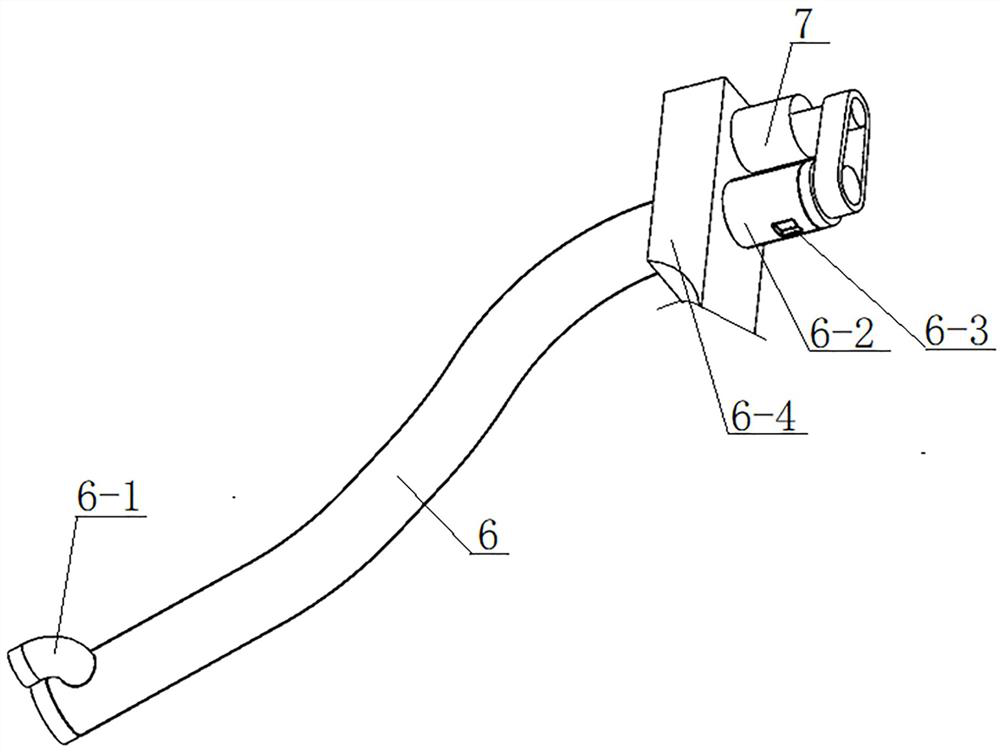

[0040] It also includes a screw feeding mechanism arranged on the top of the support 1, the screw feeding mechanism is detachably connected with the material barrel 4, and a material transfer assembly is arranged under the screw feeding mechanism, and the material transfer assembly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com