Precision instrument device buffering shock absorbing transport semitrailer

A precision instrument and semi-trailer technology, applied in the direction of transportation and packaging, vehicles used for freight, tractor-trailer combination, etc., can solve the problem that the braking impulse and deceleration cannot be reduced, and the precision instrument cannot be well protected Problems such as equipment, shock absorption, balance and buffering are limited to achieve the effects of reducing shock and vibration, reducing vibration, and slowing down shaking and shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the present invention, so that those skilled in the art can better understand the essence of the present invention and implement it.

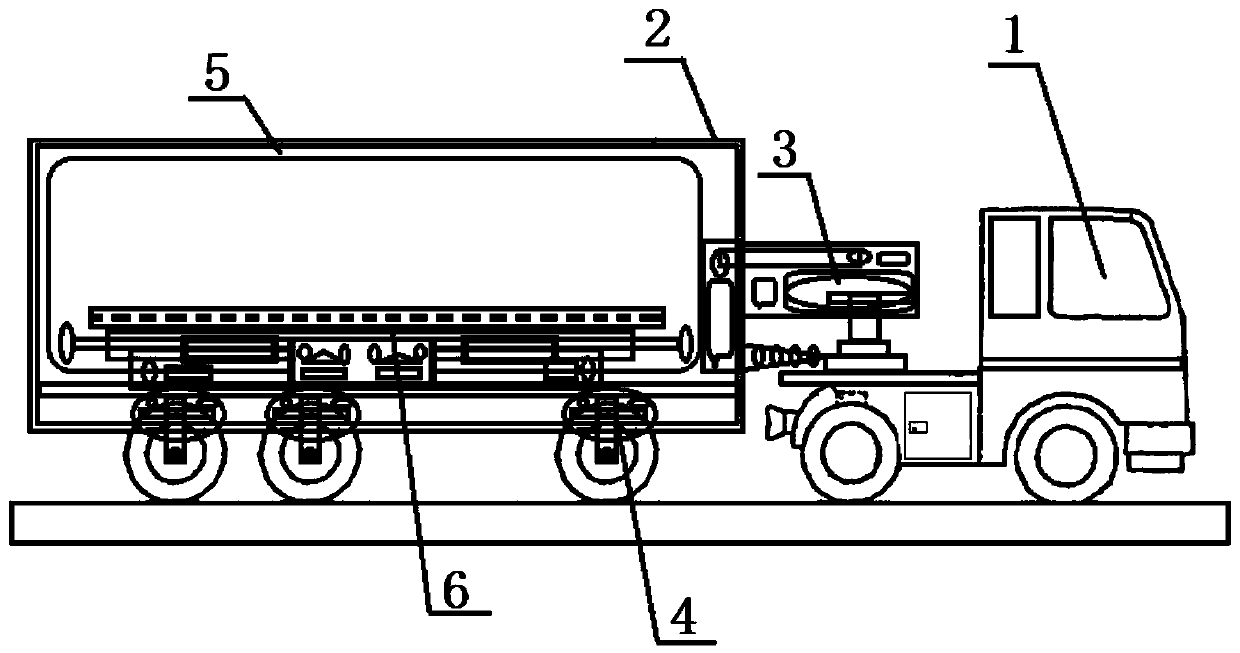

[0048] see Figure 1 to Figure 8 , a semi-trailer for cushioning and shock-absorbing transport with precision instruments and equipment, including a tractor 1 and a truck 2, the tractor 1 and the truck 2 are connected through a shock-absorbing gooseneck 3, and the truck 2 is equipped with a double shock-absorbing suspension In the system 4 , a transport compartment 5 is arranged on the truck 2 .

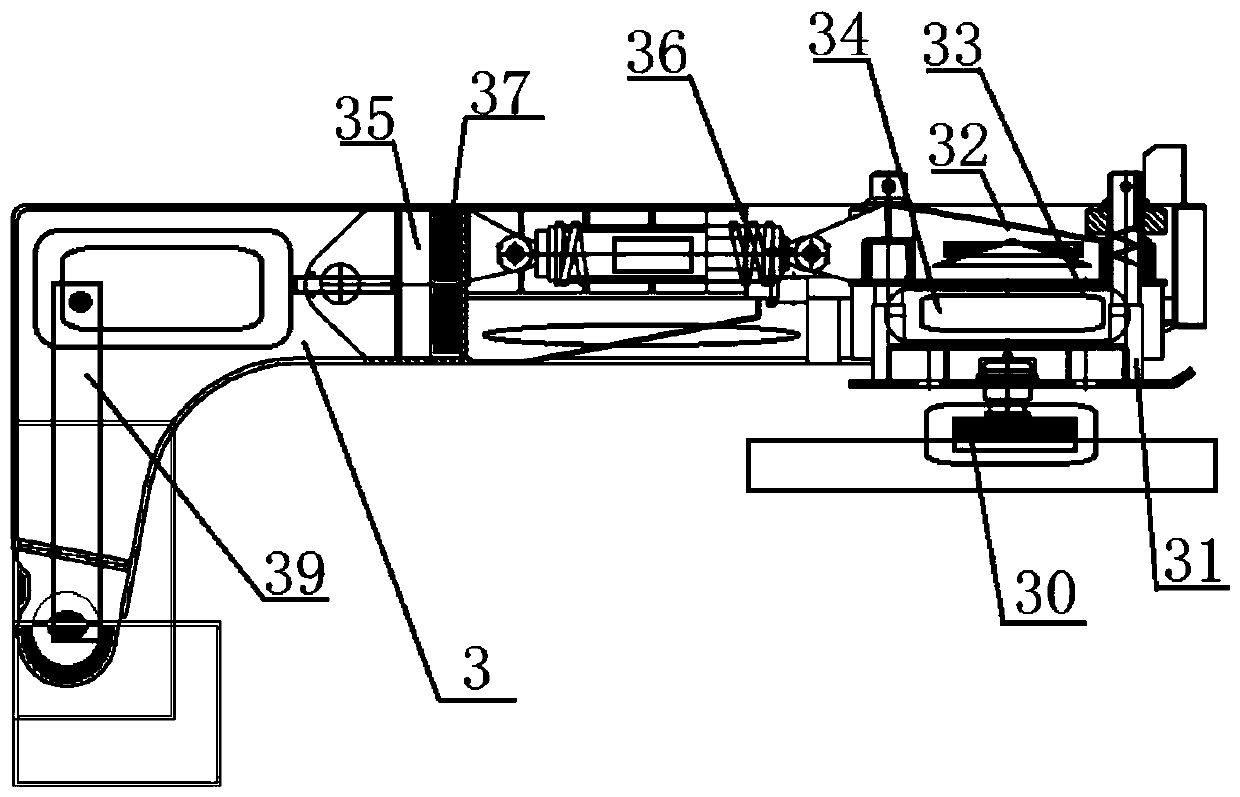

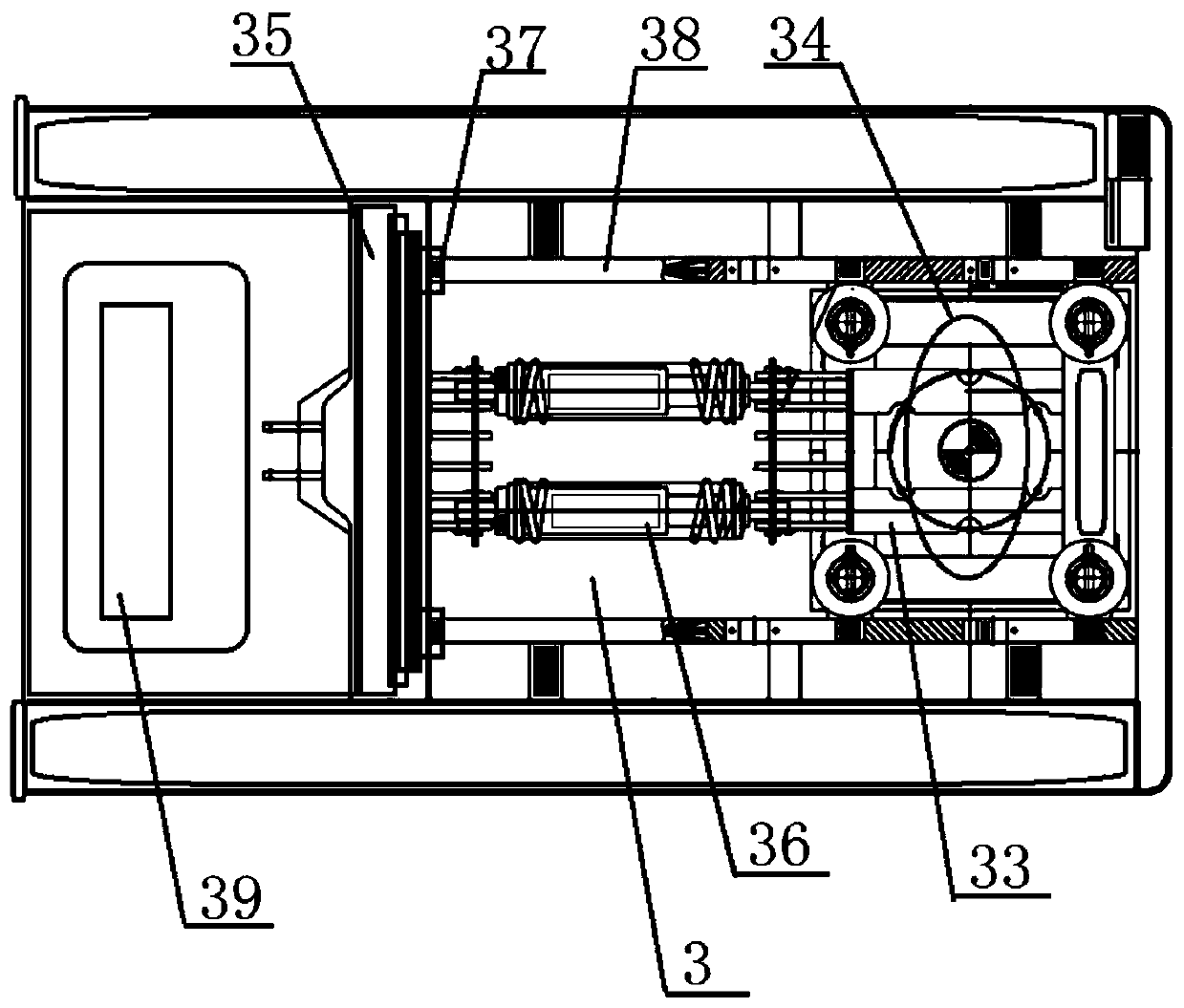

[0049] Such as figure 2 and image 3 As shown, the shock-absorbing gooseneck 3 includes a tractor pin seat 30, a pin seat sliding guide rail 31, an upper gooseneck frame 32, an airbag buffer chamber 33, a shock-absorbing airbag 34, a direction hinge, a horizontal sliding seat 35, a hydraulic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com