Electromagnetic eddy current braking device

A brake device and electromagnetic eddy current technology, which is applied in the direction of electric brake system, electric vehicle, asynchronous induction clutch/brake, etc., can solve the problem of reducing the friction coefficient of the contact surface between the magnetic track brake and the track, failing to meet the braking requirements, Non-adhesive braking and other issues, to achieve the effect of small space occupation, meeting braking requirements, and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

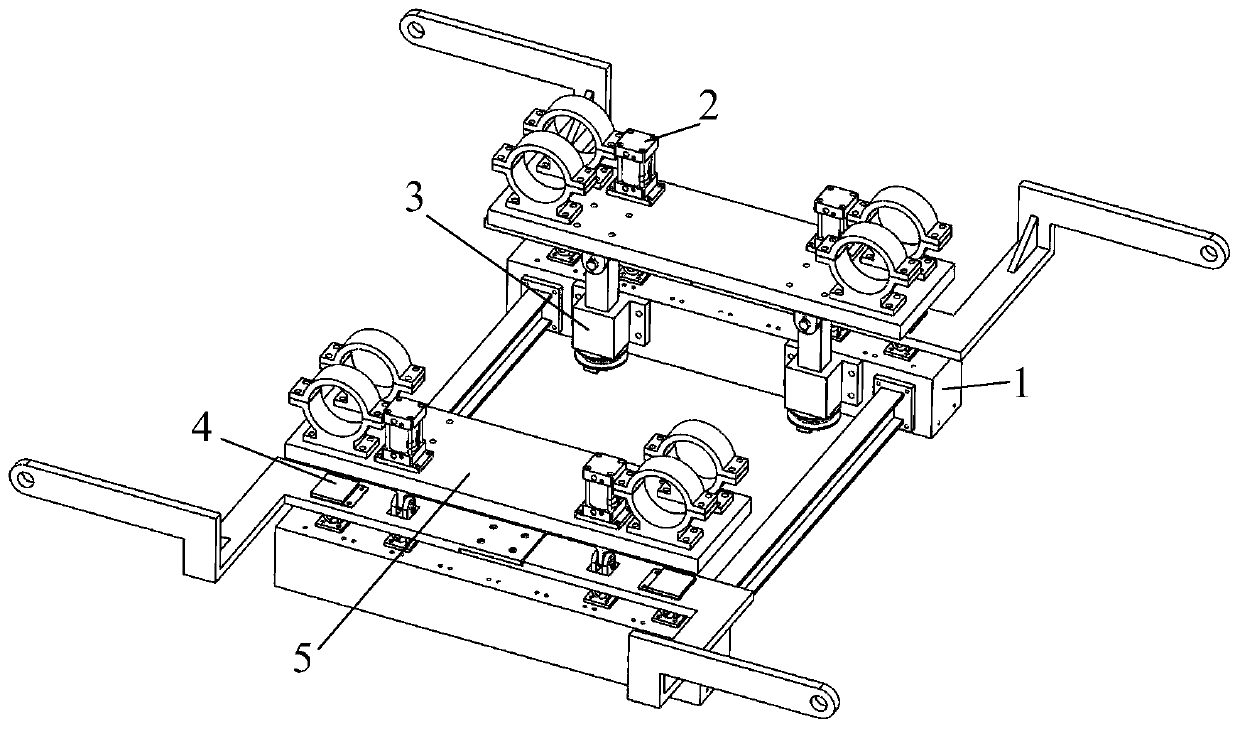

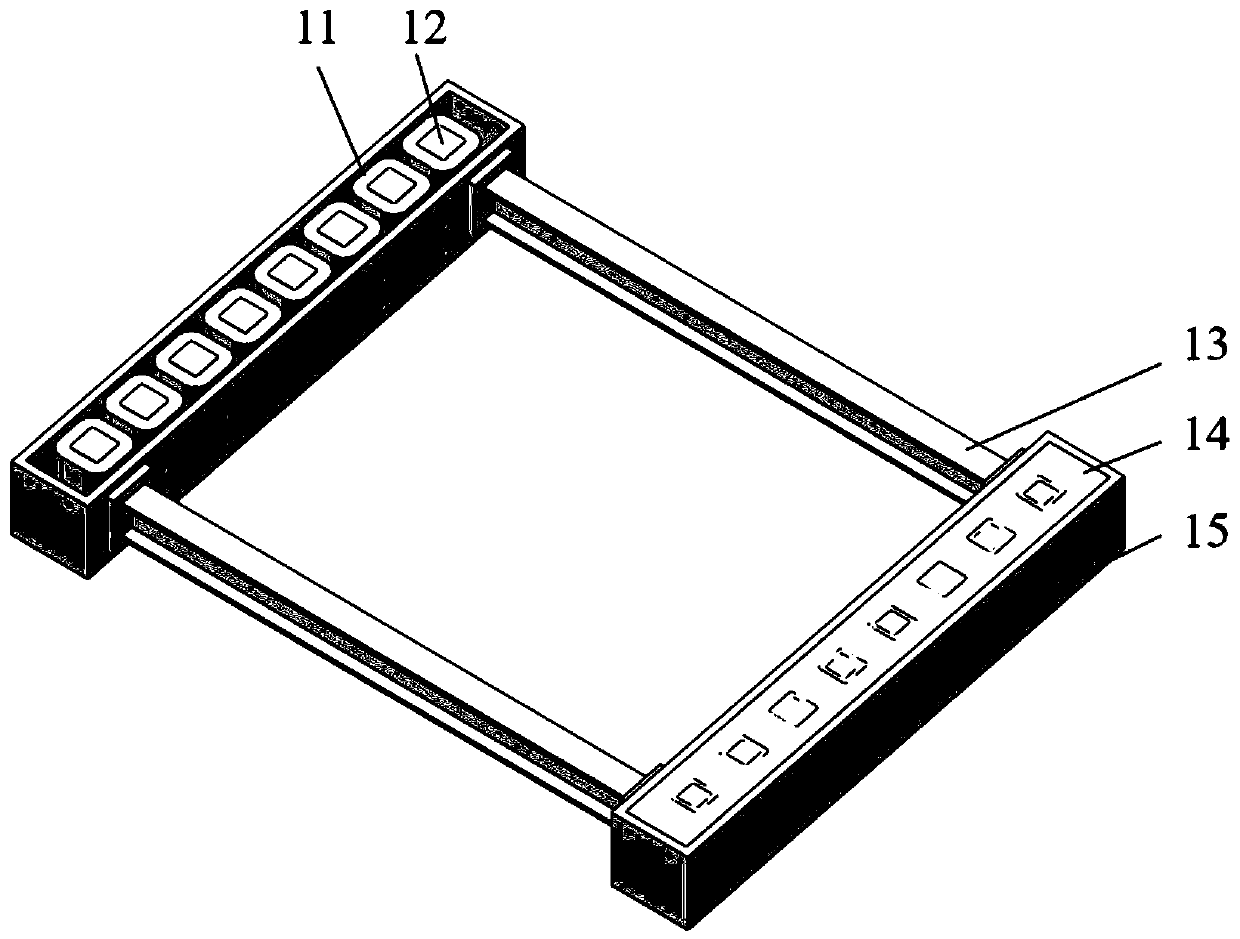

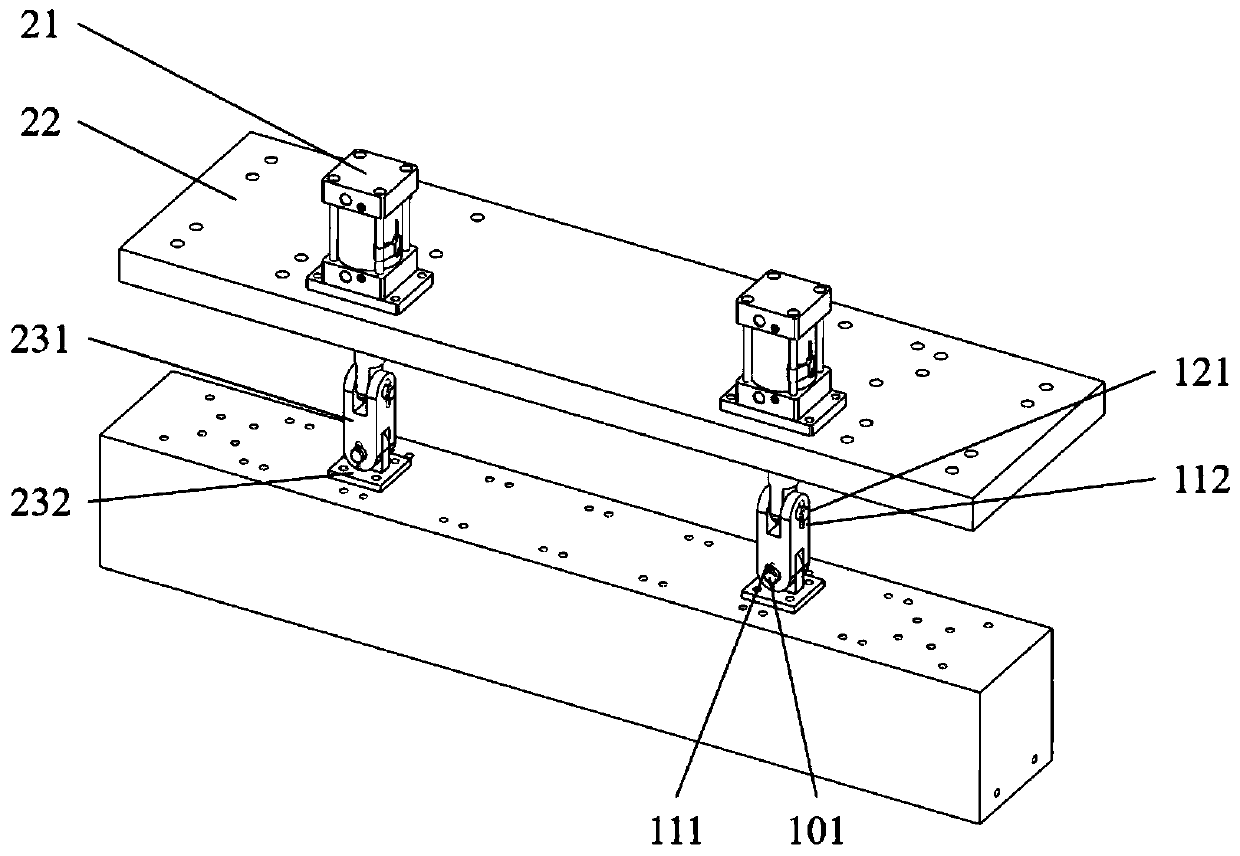

[0027] Such as figure 1 As shown, an electromagnetic eddy current braking device is composed of an excitation unit 1, a lifting device 2, a braking force transmission device 3, a gap adjustment device 4 and a support plate device 5; the excitation unit 1 is located in the braking device The lowermost end is movably connected with the lower end of the lifting device 2, the lifting device 2 is fixedly installed on the support plate device 5, the braking force transmission device 3 is installed on the inner side of the excitation unit 1, the upper end is hinged with the support plate device 5, and the lower end is connected with the support plate device 5. The excitation unit 1 is slidably connected, the gap adjustment device 4 is installed above the excitation unit 1, and is respectively connected to the train wheel shaft through the support frame 42, and the support plate de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com