Casting inoculant adding device

A technology of adding devices and inoculants, which is applied in the field of casting equipment, can solve problems such as excessive addition, insufficient inoculation, waste of inoculants, etc., and achieve the effects of ensuring the quality of rolls, reducing staffing, and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

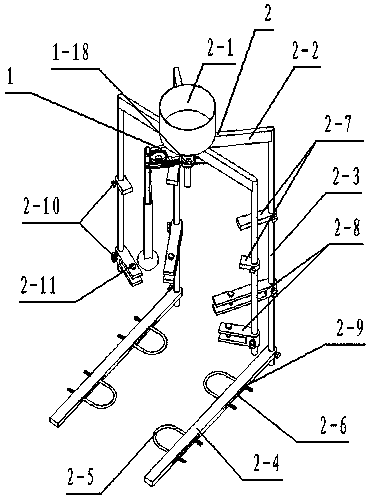

[0027] Referring to the accompanying drawings, a rolling inoculant automatic adding device installed on a pouring cup includes a support frame 2, a feeding mechanism 1, and the support frame 2 includes a hopper 2-1, a beam 2-2, and a support rod 2-3 1. The base plate 2-4, the beam 2-2 is vertically connected with the pole 2-3, the base plate 2-4 is vertically assembled on the bottom of the pole 2-3, and the hopper 2-1 is assembled on the upper end surface of the beam 2-2.

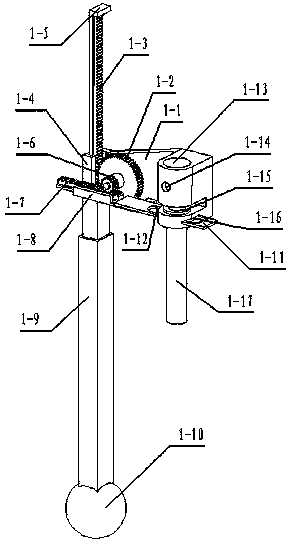

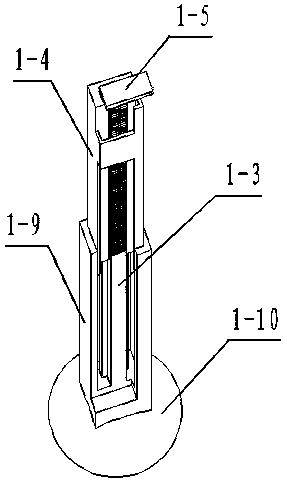

[0028] The feeding mechanism 1 includes a horizontal plate 1-1, a large gear 1-2, a large rack 1-3, a fixed sleeve 1-4, a pinion 1-6, a small rack 1-7, and a small rack groove 1 -8. Install casing 1-9, floating ball 1-10, and slide plate 1-11. The horizontal plate 1-1 is vertically welded on the top side of the fixed sleeve 1-4, and a large rack is assembled in the sleeve 1-4. 1-3, the casi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com