Organic-inorganic composite coating film on surface of metal lithium negative electrode, and preparation method

An inorganic composite, metal lithium technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of easy detachment, enlargement, electrolyte penetration into the coating film and reaction with lithium metal, etc., to improve cycle life, high flexibility , Improve the effect of electrochemical stability window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032](1) Dissolve 0.4166g of ethyl orthosilicate in 1.25g of dimethyl sulfoxide, and stir magnetically at 60°C for 7 hours to obtain a silane solution.

[0033] (2) Float the lithium slice on 1000 μL silane solution and react for 5 minutes.

[0034] (3) Rinse with dimethyl carbonate to remove excess liquid, place it in an environment with water and oxygen content ≤ 5ppm for 5 minutes, take it out, and dry it at 35°C for 3.5 hours, and a brown-gray coating film is formed on the surface.

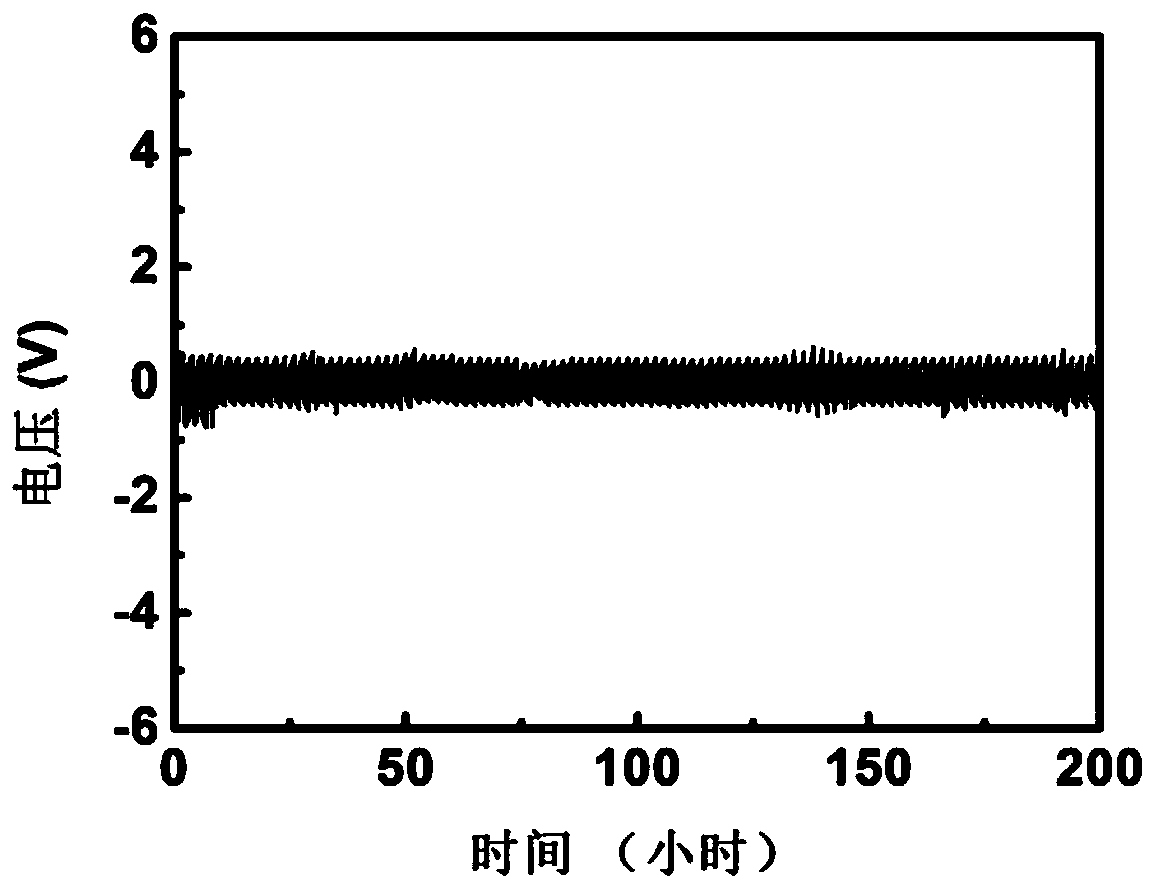

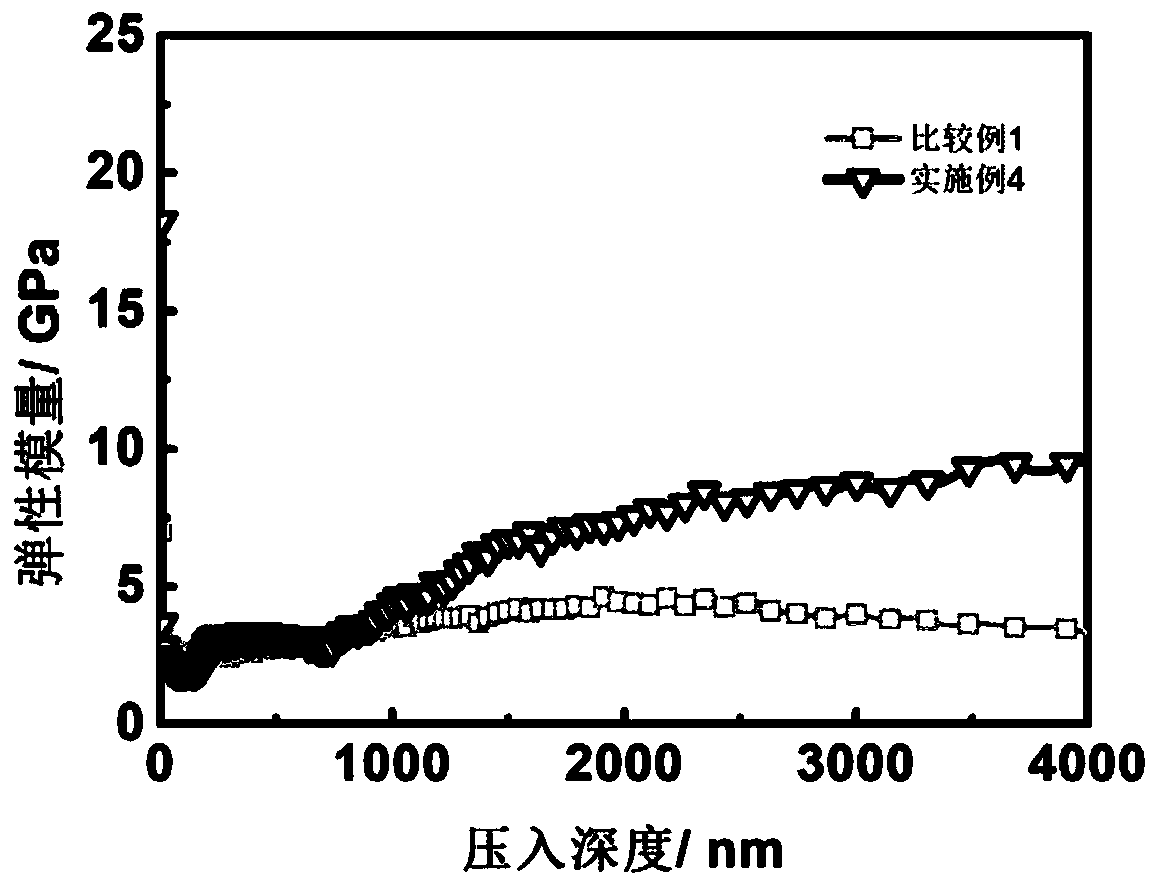

[0035] (4) Li / Li symmetric batteries were assembled using coated lithium sheets, using commercial separators and carbonate-based LiPF 6 electrolyte.

[0036] (5) After the battery cycled for one week, the organic coating film evolved in situ to form an organic-inorganic composite coating film in which inorganic particles were randomly embedded in the organic phase with a spatial network structure. The film was bonded to lithium metal through the hydroxyl formed by hydrolysis at one end. Amo...

Embodiment 2

[0039] (1) Dissolve 0.5568g of γ-glycidoxypropyltrimethoxysilane in 1.5626g of N-methylpyrrolidone, and stir magnetically at 50°C for 5h to obtain a silane solution.

[0040] (2) Spread 800 μL of silane solution evenly on the surface of the lithium sheet and react for 1 min.

[0041] (3) Rinse with dimethyl carbonate to remove excess liquid, place it in an environment with water and oxygen content ≤ 5ppm for 5 minutes, take it out, and dry it at 45°C for 3.5 hours, and a gray coating film is formed on the surface.

[0042] (4) A lithium / lithium symmetric battery was assembled using the coated lithium sheet, using a commercial separator and an ether-based LiTFSI electrolyte.

[0043] (5) After one cycle of the battery, the organic coating film evolves in situ to form an organic-inorganic composite coating film in which inorganic particles are randomly embedded in the organic phase with a spatial network structure. metal bonding. Among them, the particle size of inorganic part...

Embodiment 3

[0046] (1) Dissolve 0.7854g (3-mercaptopropyl)trimethoxysilane in 1.7558g N-methylpyrrolidone, and stir magnetically at 65°C for 5.5h to obtain a silane solution.

[0047] (2) Spread 1000 μL of silane solution evenly on the surface of the lithium sheet and react for 8 minutes.

[0048] (3) Rinse with dimethyl carbonate to remove excess liquid, place it in an environment with water and oxygen content ≤ 5ppm for 5 minutes, take it out, and dry it at 50°C for 3.5 hours, and an off-white coating film is formed on the surface.

[0049] (4) A lithium / lithium symmetric battery was assembled using the coated lithium sheet, using a commercial separator and a carbonate-based LiODFB electrolyte.

[0050] (5) After one cycle of the battery, the organic coating film evolves in situ to form an organic-inorganic composite coating film in which inorganic particles are randomly embedded in the organic phase with a spatial network structure. The film is formed by bonding the active sulfhydryl g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com