Monocrystal-like lithium nickel cobalt manganese composite oxide material and preparation method thereof

A nickel-cobalt-manganese oxide and composite oxide technology, which is used in electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of complex process and high equipment requirements, improve material capacity, improve circulation, and simplify production processes. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Select Ni with a D50 of 3.3 μm 0.6 co 0.1 mn 0.3 (OH) 2 For the precursor, the precursor is mixed with lithium carbonate at a molar ratio of 1.06, and 0.007% of B element and 0.015 mole of Zr element are added. B source uses H 3 BO 3 , Zr source using ZrO 2 . Mix well in a high speed mixer. The homogeneously mixed materials were placed in a sintering furnace to raise the temperature to 910°C at a rate of 3°C / min and keep the temperature for 12h. After that, it is cooled to room temperature with the temperature of the furnace, and crushed by a crusher. The crushed material is mixed with 0.15% Al (Al source is Al 2 o 3 ) and mix evenly, raise the temperature to 700°C at a heating rate of 3°C / min in the sintering furnace and keep it warm for 6h. With the furnace temperature down to room temperature. Then sieve to get the finished material.

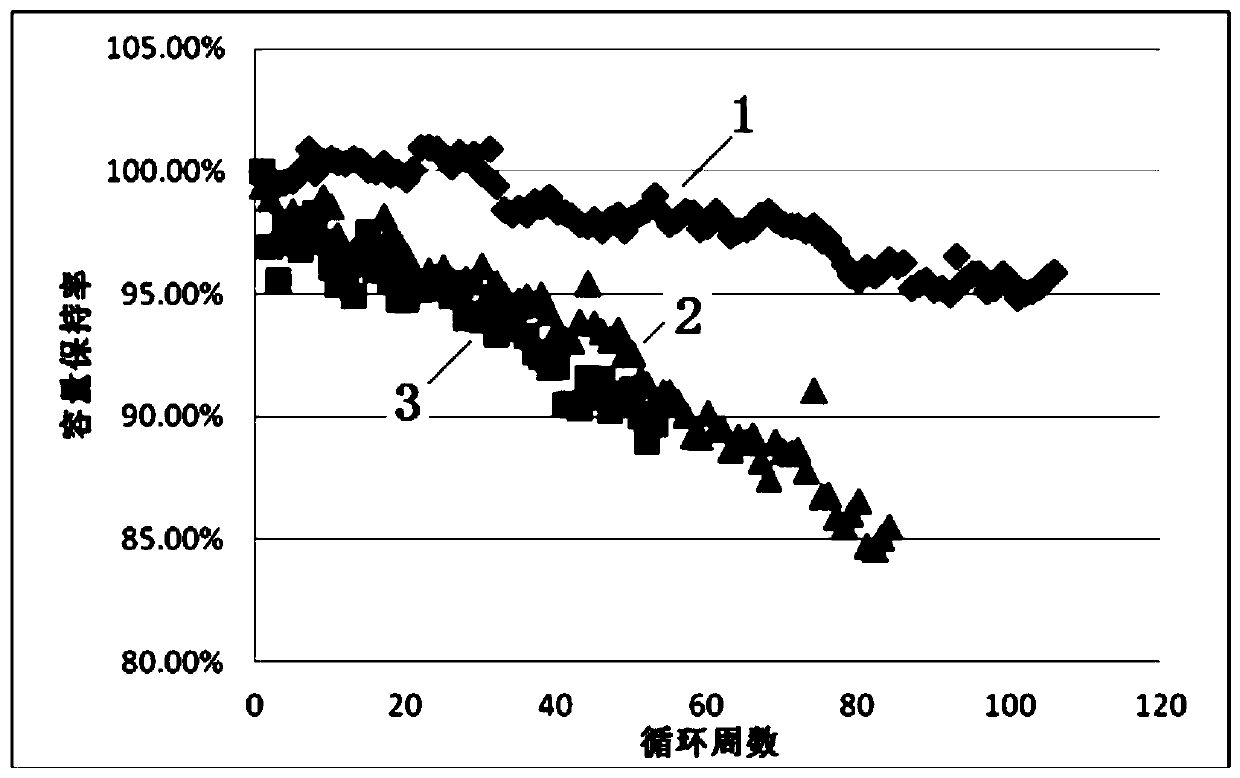

[0034] Mix the above-mentioned finished materials, acetylene black, KS-6, and PVDF according to the mass ratio of 9.0︰0....

Embodiment 2

[0039] Select Ni with a D50 of 2.0 μm 0.8 co 0.1 mn 0.1 (OH) 2 Precursor, using lithium hydroxide and 0.15% Sr (Sr source is Sr(OH) 2 ), the primary sintering temperature is 750°C. Except described condition, other is identical with embodiment 1.

Embodiment 3

[0041] Select Ni with a D50 of 6.0 μm 0.5 co 0.2 mn 0.3 (OH) 2 For the precursor, use 0.1% Sr (Sr source is SrO), and the primary sintering temperature is 970° C., except for the above conditions, the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com