Battery diaphragm having fast charging function

A diaphragm and battery technology, applied in the field of battery diaphragm, to achieve the effects of good heat resistance and puncture strength, good molding, and improved porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

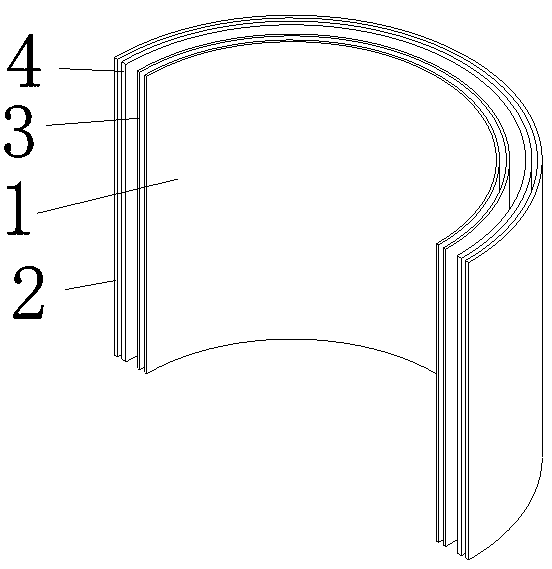

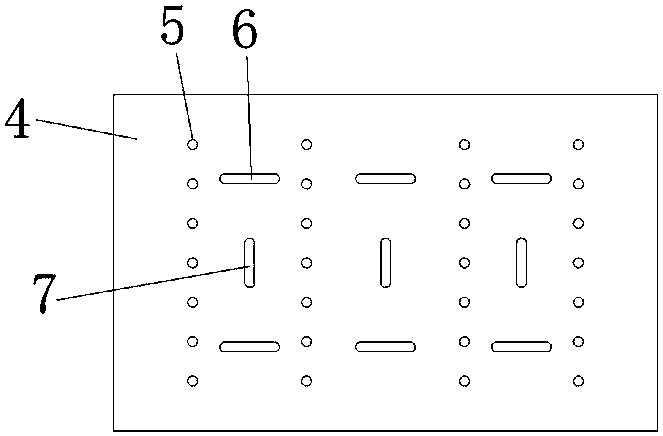

[0032] Example 1: See Figure 1-2 , a separator for a battery with a fast charging function, comprising a positive electrode 1, a negative electrode 2, a diaphragm a3 and a diaphragm b4, the diaphragm a3 and the diaphragm b4 are both arranged between the positive electrode 1 and the negative electrode 2, and the diaphragm a3 is arranged on the diaphragm b4 On the inner side, the thickness of the diaphragm a3 is half of the thickness of the diaphragm b4, and the manufacturing process and materials of the diaphragm a3 and the diaphragm b4 are the same, the diaphragm b4 is provided with holes 5, the holes 5 run through the front and back of the diaphragm b4, and the entire wall of the diaphragm b4 is provided with eight rows of holes 5 , and there are seven holes 5 vertically, and seven holes 5 are equidistantly opened, and each row of holes 5 is equidistantly opened, and the gap between each row of holes 5 is provided with two horizontal grooves 6 and one vertical groove 7, and ...

Embodiment 2

[0034] Embodiment 2: a kind of preparation method of the separator for battery with fast charge function, comprises the following steps:

[0035] S1. Preparation of mixed particles:

[0036] S1.1. Put 2 parts of cocamidopropyl amine oxide, 3 parts of lauryl amidopropyl amine oxide, 40 parts of absolute ethanol, 2 parts of ammonia water, and 100 parts of water into the reactor in corresponding parts by weight, and heat to keep The temperature in the reaction kettle was 40°C, and the mixture A was obtained after continuous stirring for 25 minutes;

[0037] S1.2. Add tetraethyl orthosilicate which is 6 times the total mass of mixture A to the reaction kettle treated in S1.1, heat to keep the temperature in the reaction kettle at 38°C, and keep stirring for 15 minutes to obtain mixture B for later use;

[0038]S1.3. Add a composite solution of 10% of the total mass of mixture B to the reactor after S1.2, then heat to keep the temperature in the reactor at 55°C, and obtain mixture...

Embodiment 3

[0043] Embodiment 3: a kind of preparation method of the separator for battery with fast charge function, comprises the following steps:

[0044] S1. Preparation of mixed particles:

[0045] S1.1. Put 4 parts of cocamidopropyl amine oxide, 6 parts of lauryl amidopropyl amine oxide, 43 parts of absolute ethanol, 3 parts of ammonia water, and 105 parts of water into the reactor in corresponding parts by weight, and heat and keep The temperature in the reaction kettle was 45°C, and the mixture A was obtained after continuous stirring for 30 minutes;

[0046] S1.2. Add tetraethyl orthosilicate which is 9 times the total mass of mixture A to the reaction kettle treated in S1.1, heat to keep the temperature in the reaction kettle at 42°C, and keep stirring for 20 minutes to obtain mixture B for later use;

[0047] S1.3. Add a composite solution of 15% of the total mass of mixture B to the reactor after S1.2, then heat to keep the temperature in the reactor at 60°C, and obtain mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com