Lining module and fully enclosed submerged arc furnace lining damage repair method

A submerged arc furnace, fully enclosed technology, applied in the field of smelting furnace equipment and facilities, can solve the problems of affecting the normal production of submerged arc furnace, affecting the economic benefits of smelting, and large economic losses, so as to reduce adverse effects and reduce downtime for maintenance , The effect of reducing maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

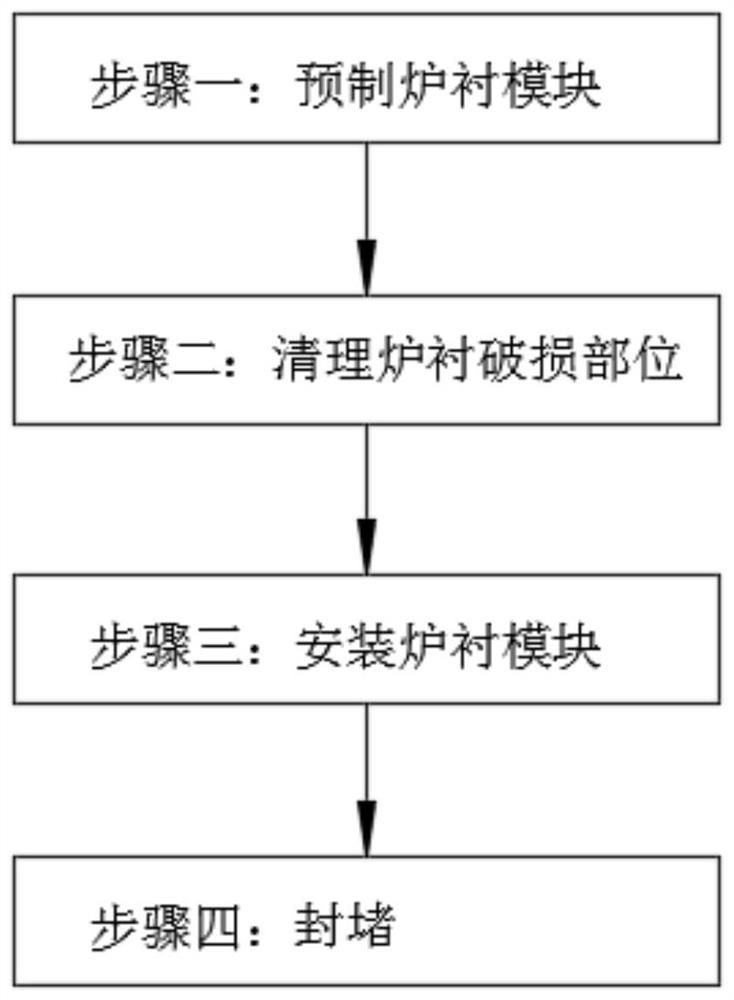

[0024] In order to further illustrate the technical means and effects of the present invention for solving technical problems, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the provided accompanying drawings are schematic and mutually exclusive They are not drawn to scale or scale, and therefore the drawings and specific examples are not intended to limit the scope of protection claimed by the invention.

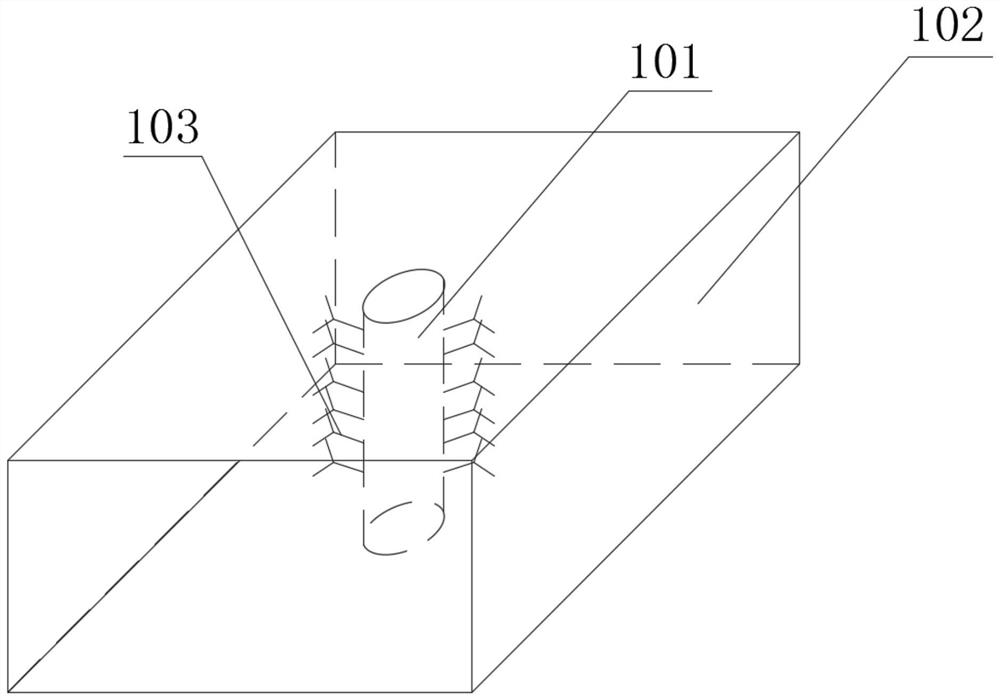

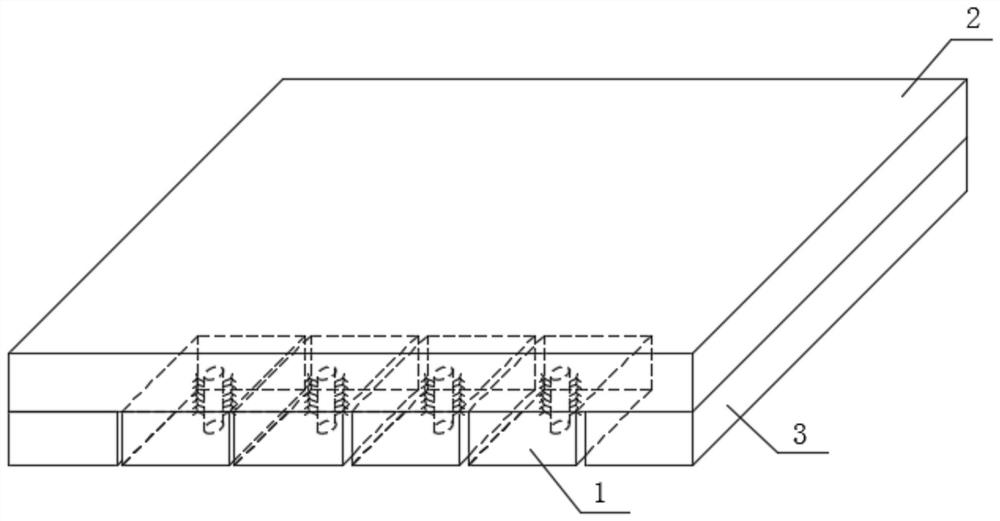

[0025] Such as figure 1 The optional embodiment of the furnace lining module shown includes an anchor 101 and a furnace lining material 102. The anchor 101 includes a hollow heat-resistant pipe and a fastening bar 103, and the fastening bar 103 is arranged on the outer surface of the hollow heat-resistant pipe to form a Tree root type, the lining material 102 can be corundum lining material; the anchor 101 is arranged in the lining material 102, the outer surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com