Composite conveying pipeline

A technology of conveying pipelines and conveying passages, which is applied in the direction of pipeline protection and protection of pipelines and pipes through thermal insulation, can solve the problems of economic loss, single pipeline structure, poor fluidity, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

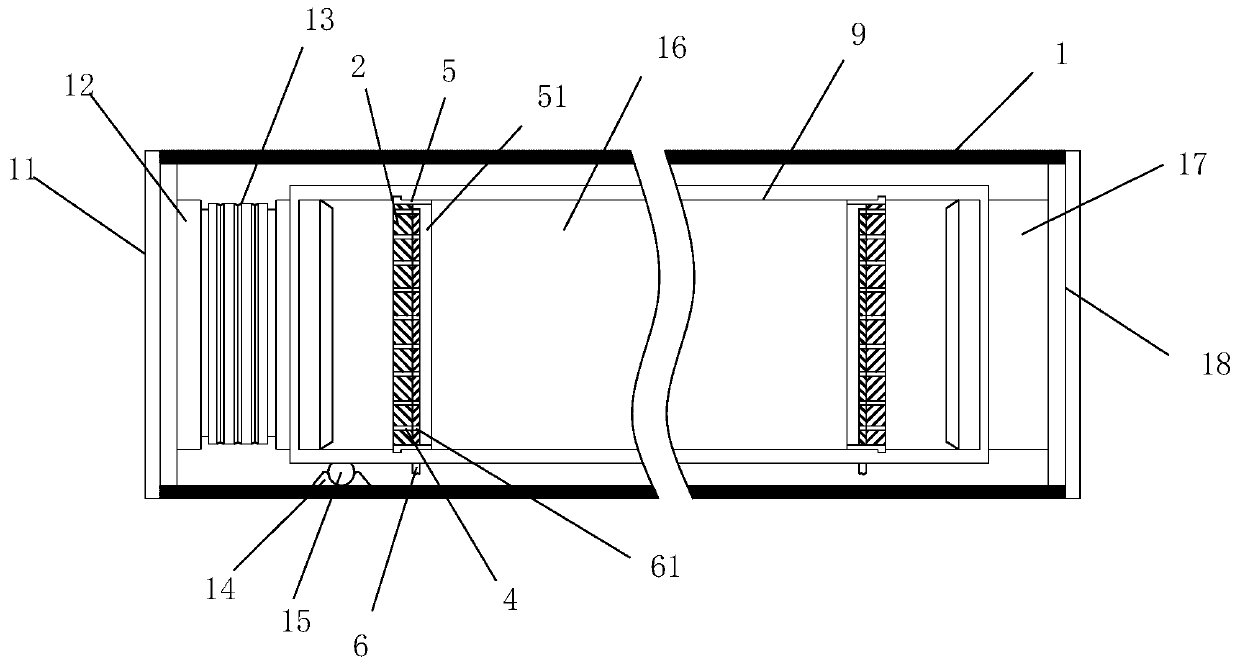

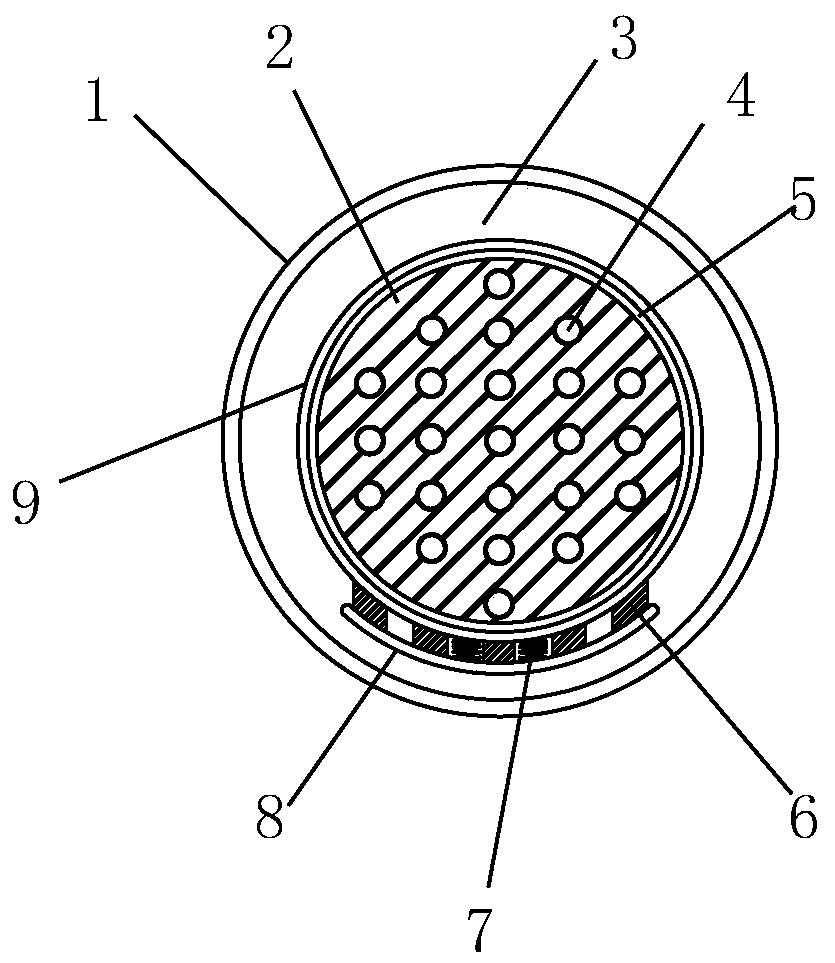

[0018] Such as figure 1 and figure 2 As shown, the composite delivery pipeline includes an outer tube 1 and an inner tube 9, the inner tube 9 is suspended in the hollow cavity 3 inside the outer tube 1, and a first sealing cover 11 is arranged on one side of the outer tube 1, The other side of the outer tube 1 is provided with a second sealing cover 18, the first sealing cover 11 and the second sealing cover 18 seal the two sides of the whole outer tube 1, and there is an inner conveying channel 16 in the middle of the inner tube 9, the first The inner end portion of the sealing cover 11 is provided with a first assembly convex portion 12, and the inner end portion of the second sealing cover 18 is provided with a second assembly convex portion 17, and the first assembly convex portion 12 and the second assembly convex portion 17 all seal the entire Inner conveying passage 16, more than one sealing device is equidistantly installed in the inner conveying passage 16, a sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com