Hollow impact drill

A technology of percussion drilling and gravity, applied in drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of increased economic cost and time cost, increased engineering volume, uneven distribution, etc., to improve drilling efficiency and improve punching. Efficiency, good hole forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

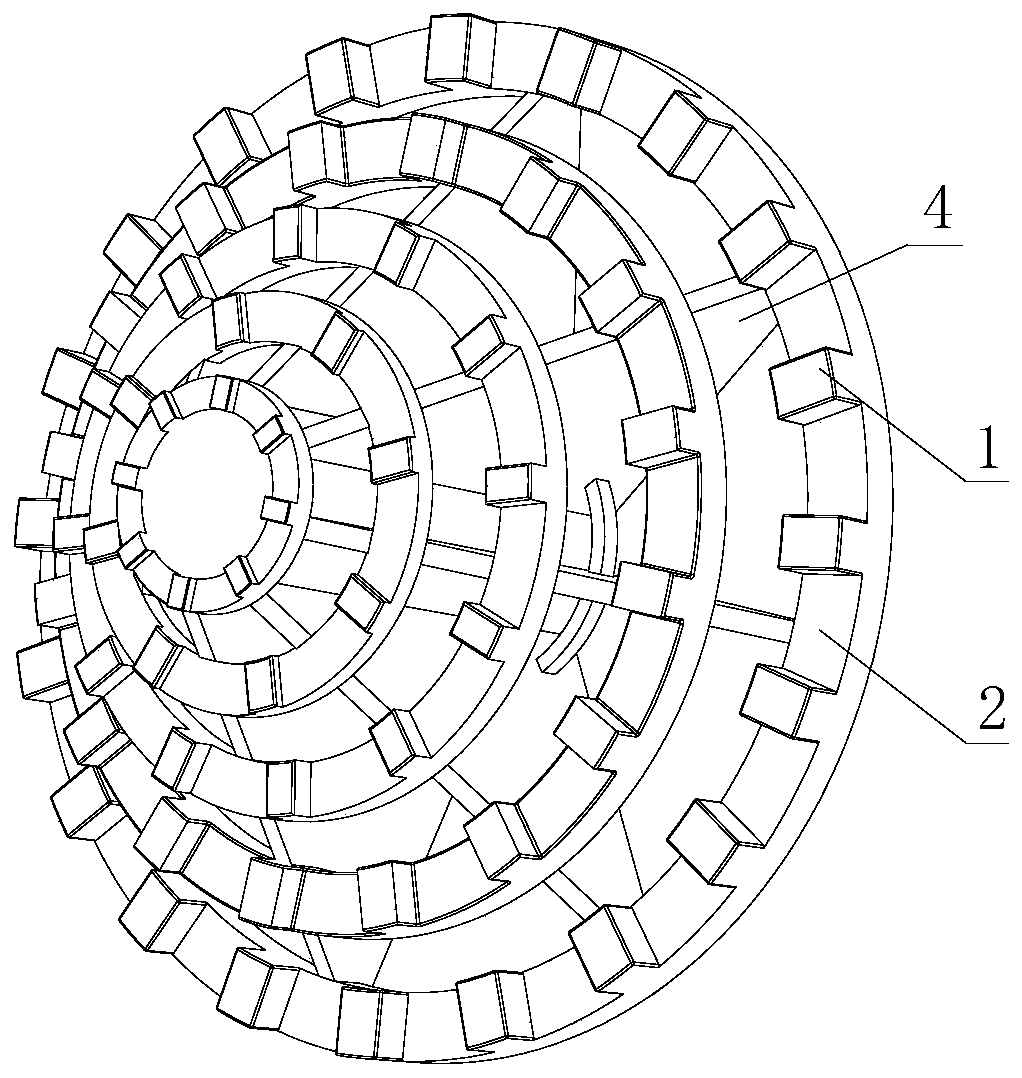

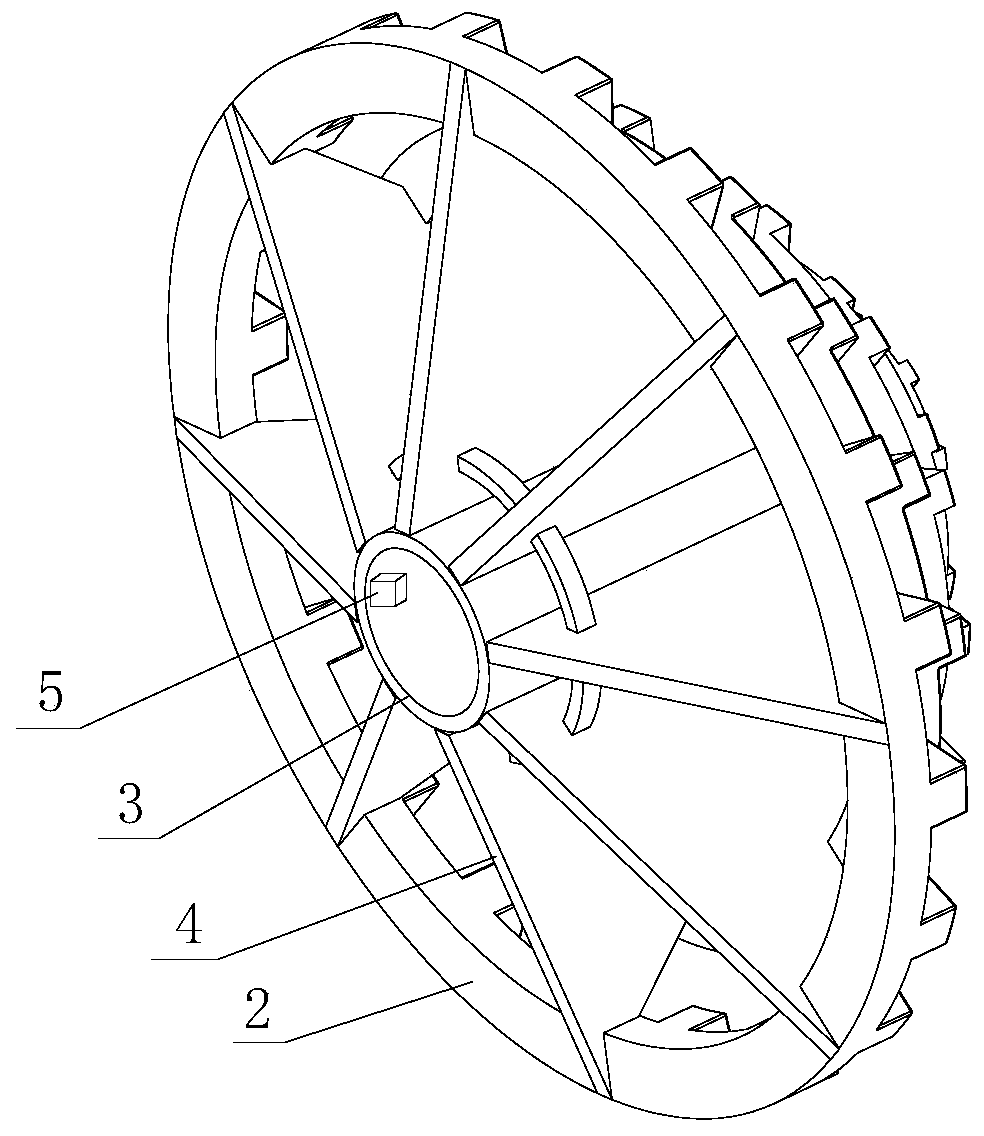

[0024] Such as figure 1 As shown, a hollow impact drill includes a gravity cylinder 3, a plurality of gravity plates 4 and a plurality of annular gravity rings 2 of different diameters. The gravity cylinder 3 is located in the center of the hollow impact drill; the annular gravity circles 2 are coaxially arranged with the gravity cylinder 3, that is, the central axes of all the annular gravity circles 2 coincide with the central axis of the gravity cylinder 3.

[0025] Ring-shaped gravity rings 2 with different diameters are distributed stepwise along the length direction of the gravity cylinder 3 from small to large, and a plurality of ring-shaped gravity rings 2 and one end of the gravity cylinder 3 form a tapered drill bit. A gap is left between two adjacent annular gravity circles 2, so that the stones or muck formed during piling have sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com