Polyaspartic acid ester polyurea composite material and preparation method thereof

A technology of polyaspartate and composite materials, applied in the field of special protective materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

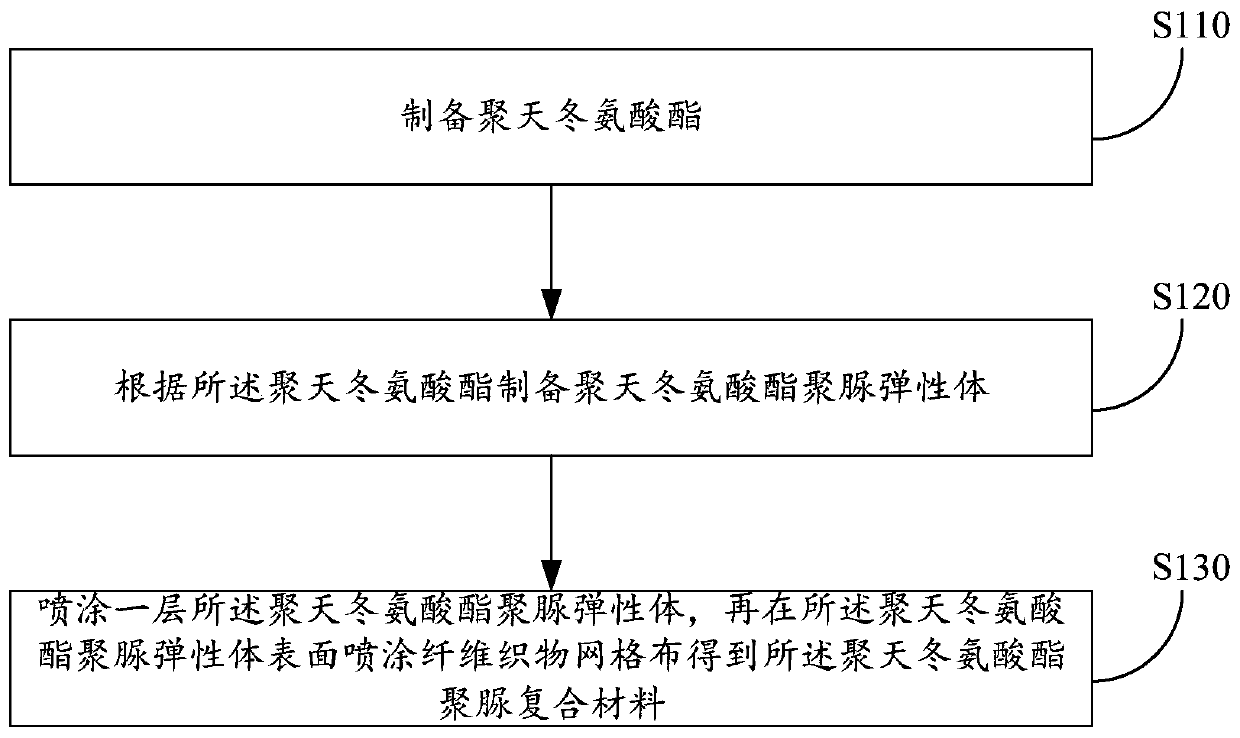

[0035] see figure 1 , a flow chart of the steps for the preparation method of a polyaspartate polyurea composite material provided by the invention, comprising the following steps:

[0036] Step S110: preparing polyaspartic acid ester;

[0037] In some preferred embodiments, in the step of preparing polyaspartic acid ester, the following steps are specifically included:

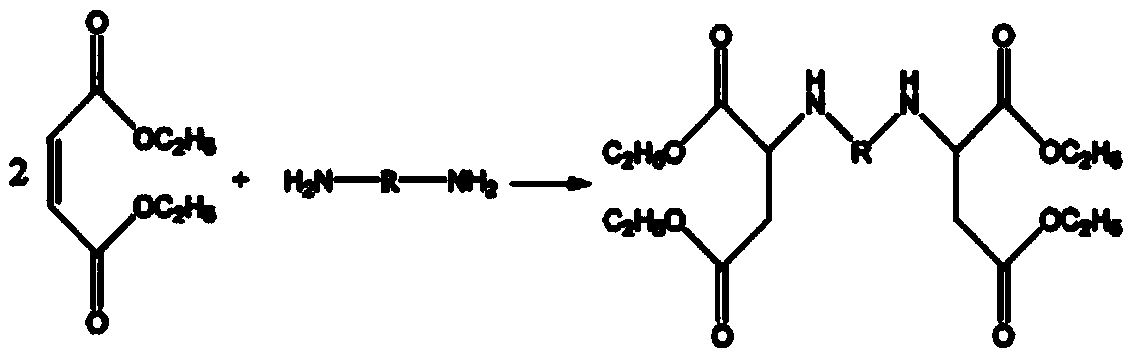

[0038] Under an inert gas environment, the aliphatic diamine and the alkyl maleic acid ester are mixed and reacted for 12 to 24 hours to obtain the polyaspartic acid ester, wherein:

[0039] The aliphatic diamines include ethylenediamine, butylenediamine, hexamethylenediamine, methylpentanediamine, isophoronediamine, 4,4,-diamino-dicyclohexylmethane (HMDA), 3, At least one of 3,-dimethyl-4,4,-diaminodicyclohexylmethane and methylcyclohexanediamine;

[0040]The alkyl maleate includes at least one of dimethyl maleate, diethyl maleate, dipropyl maleate, dibutyl maleate and diphenyl maleate.

[0041] It can b...

Embodiment 1

[0063] Synthesis of HMDA / DEM type polyaspartate:

[0064] (1) In a 1000ml four-necked flask equipped with a stirrer, a thermometer, a nitrogen tube inlet, and a dropping funnel, add 210 grams (1mol) of 4,4,-diaminodicyclohexylmethane (HMDA), start stirring and pass into nitrogen.

[0065] (2) Slowly add 344 grams (2mol) of diethyl maleate (DEM) dropwise from the dropping funnel, keep the temperature at 40°C±°C, finish the dropwise addition within 2h, heat the oil bath to 90°C-100°C, and react 12~16h.

[0066] (3) Measure the degree of unsaturation by mercaptan-iodine titration analysis method to determine the degree of chemical reaction. After the reaction is completed, cool down and discharge the material.

[0067] The main technical parameters:

[0068] parameter index Appearance (visual inspection) yellowish transparent liquid Solid content, % ≥95% NH equivalent, g / mol 277 Viscosity, mPa·s / 25℃ 1100~1500

Embodiment 2

[0070] Synthesis of IPDA / DBM type polyaspartate:

[0071] (1) In a 1000ml four-neck flask equipped with a stirrer, a thermometer, a nitrogen tube inlet, and a dropping funnel, add 170 grams (1mol) of isophoronediamine (IPDA), start stirring and feed nitrogen.

[0072] (2) Slowly add 456 g (2 mol) of dibutyl maleate (DBM) dropwise from the dropping funnel, keep the temperature at 55°C to 65°C, add dropwise within 30min to 60min, and react for 24h.

[0073] (3) Measure the degree of unsaturation by mercaptan-iodine titration analysis method to determine the degree of chemical reaction. After the reaction is completed, cool down and discharge the material.

[0074] The main technical parameters:

[0075] parameter index Appearance (visual inspection) yellowish transparent liquid Solid content, % ≥95% NH equivalent, g / mol 313 Viscosity, mPa·s / 25℃ 800~1100

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com