Groove processing and mounting process

An installation process and groove technology, which is applied in the field of groove processing and its installation process, can solve the problems of affecting the processing accuracy and high requirements for the operation of the staff, and achieve the effect of improving safety, simple on-site operation, and improving processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings.

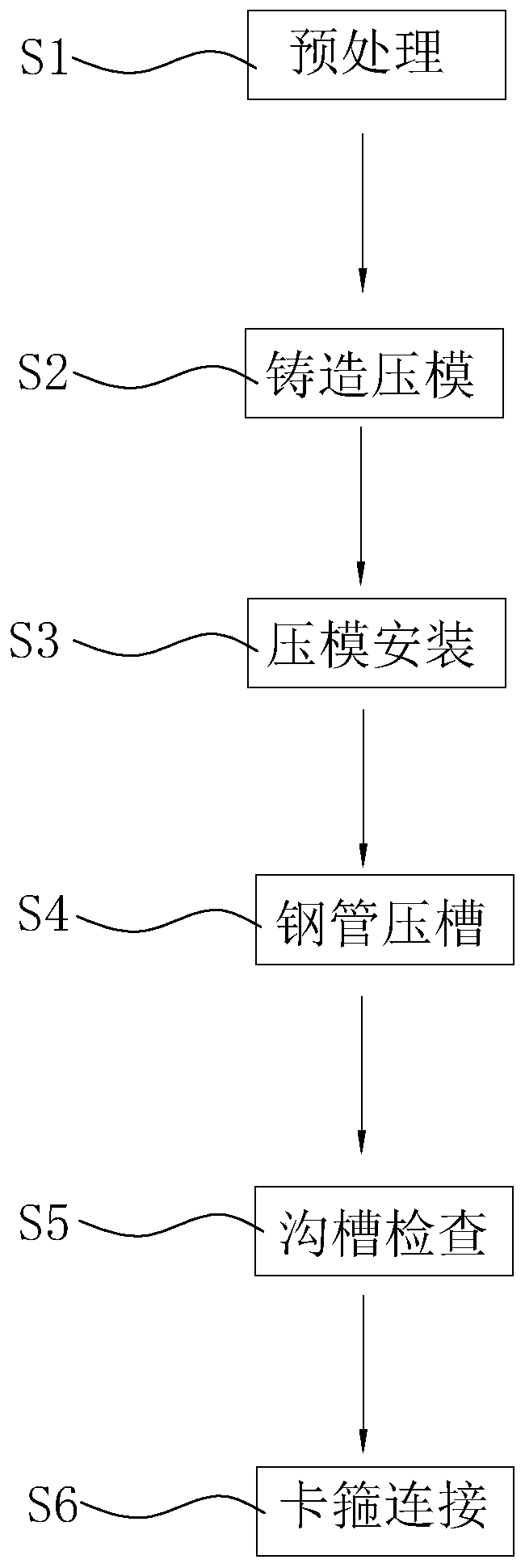

[0054] refer to figure 1 , is a groove processing and installation process disclosed by the present invention, comprising the following steps:

[0055] Step S1: Pretreat the steel pipe, first cut off the steel pipe according to the size required for installation, and then polish the burrs on the fracture of the steel pipe while removing impurities;

[0056] Step S2: measure the size of the groove required for steel pipe connection to obtain measurement data, then manufacture a mold according to the measurement data to obtain a casting mold, and finally cast the required die through the casting mold;

[0057]Step S3: Install the die on the abutment position between the grooving device and the steel pipe; Step S4: Use the grooving machine to grooving the steel pipe, first check the operation of the machine, and at the same time place the steel pipe on the groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com