A Method for Predicting Internal Oxidation Morphology of Unidirectional Ceramic Matrix Composites under Stressed Water Vapor Environment

A composite material and internal oxidation technology, which is applied in design optimization/simulation, chemical process analysis/design, instruments, etc., can solve problems such as the inability to predict the internal oxidation morphology of unidirectional ceramic matrix composites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

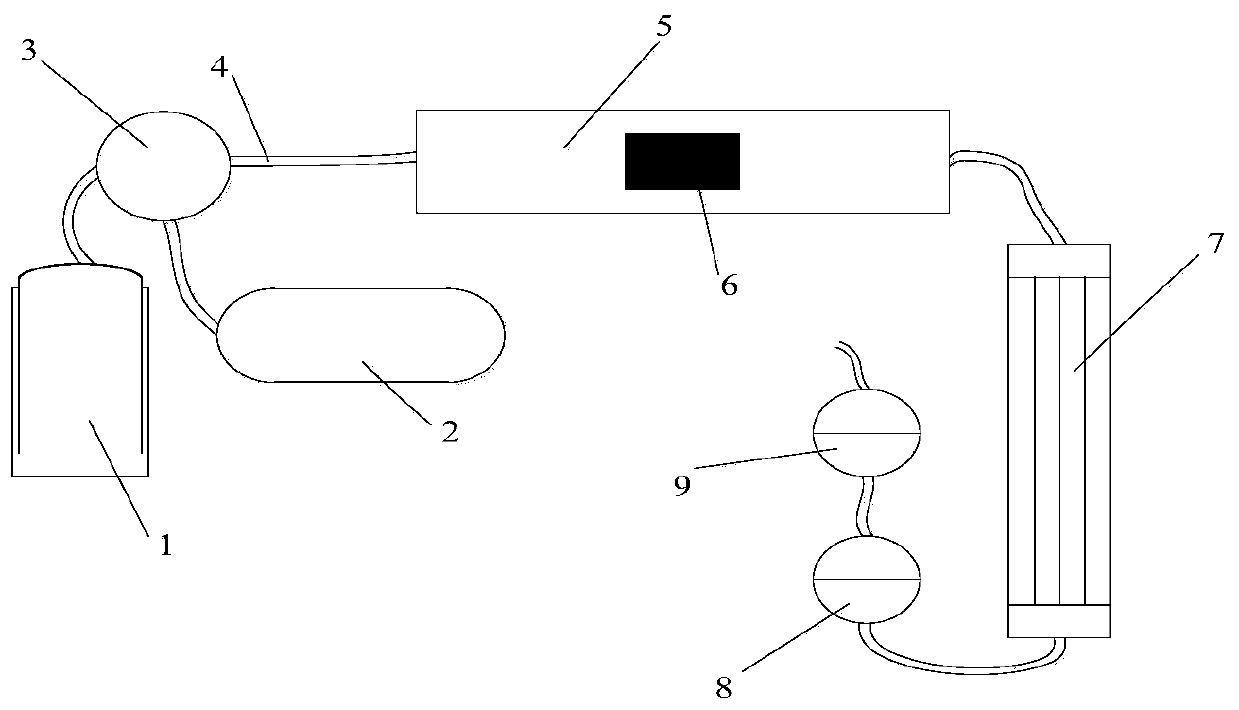

Method used

Image

Examples

Embodiment 1

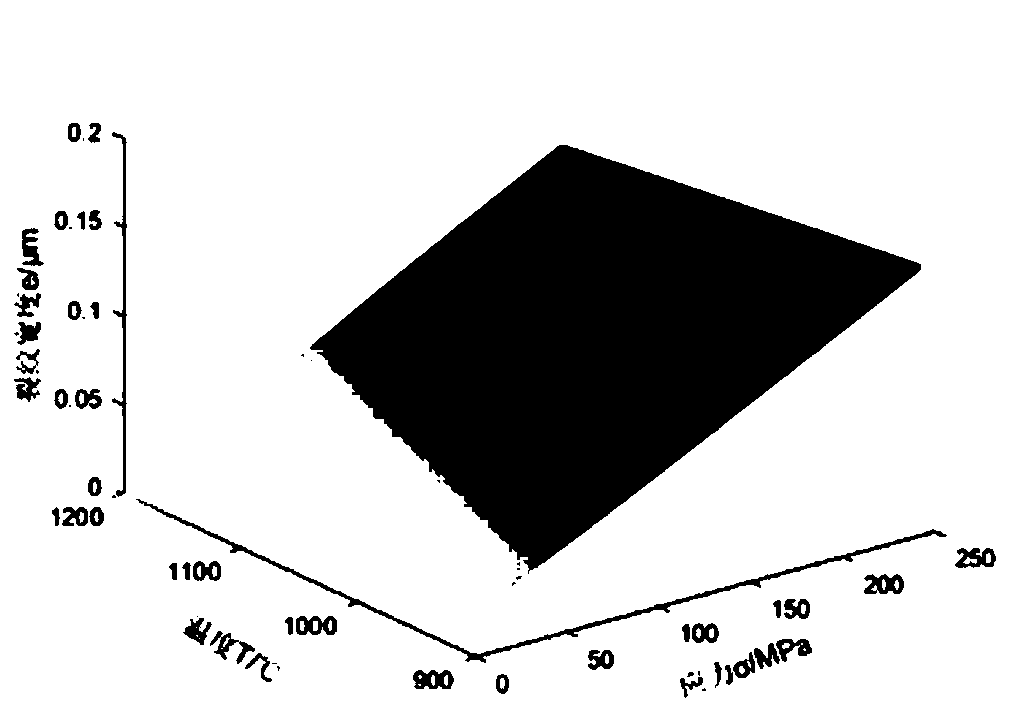

[0152] In this embodiment 1, the unidirectional ceramic matrix composite material is subjected to a method for predicting the internal oxidation morphology of the material under a stress water vapor oxidation environment at 900-1200°C, which specifically includes the following steps:

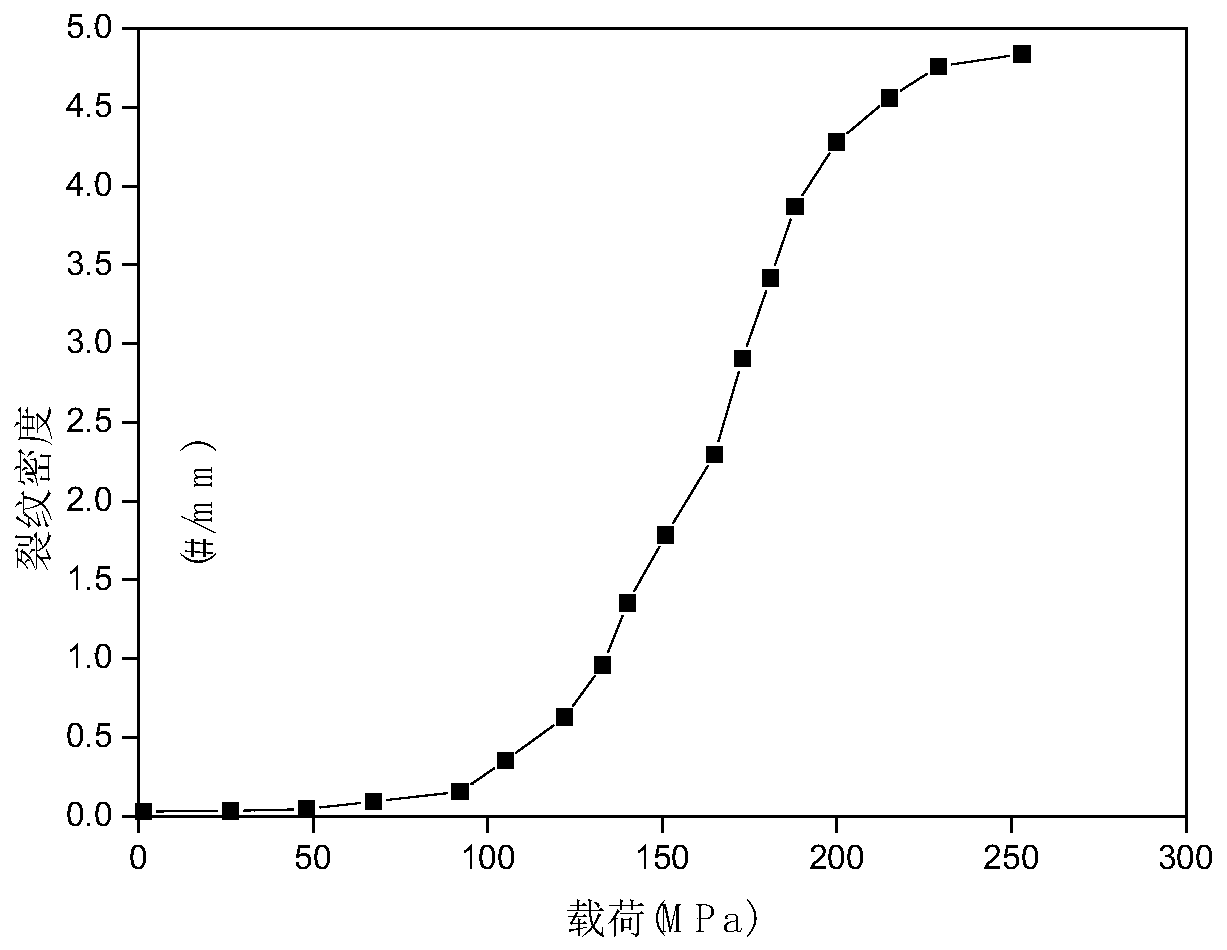

[0153] Step (1), determining the number of cracks in the unidirectional ceramic matrix composite material matrix: considering the thermal residual stress, and according to the stress borne by the matrix under the action of tensile stress, determine the change of the number of cracks in the matrix with stress;

[0154] Step (1) specifically includes the following steps:

[0155] The strength of the unidirectional ceramic matrix composite matrix has a certain dispersion, and the cracking of the matrix under stress is a random process. Assuming that the failure probability of the matrix obeys the Poisson distribution, the probability that the matrix will fail due to at least one crack under stress ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com