Gate drive current charging circuit and gate drive control circuit of power device

A charging circuit and power device technology, which is applied in the direction of control/regulation systems, instruments, and adjustment of electrical variables, etc., can solve problems such as low flexibility, low reliability, and low adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

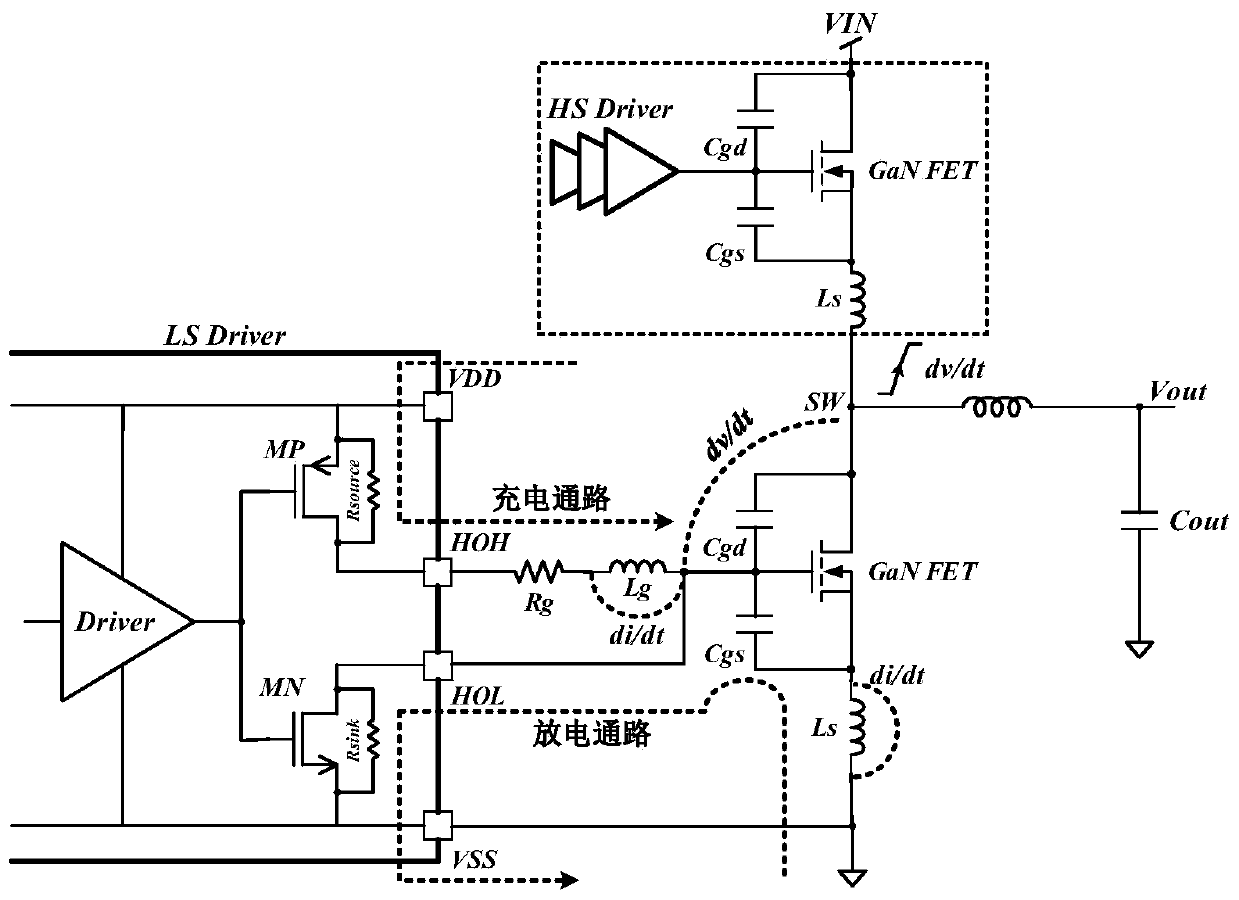

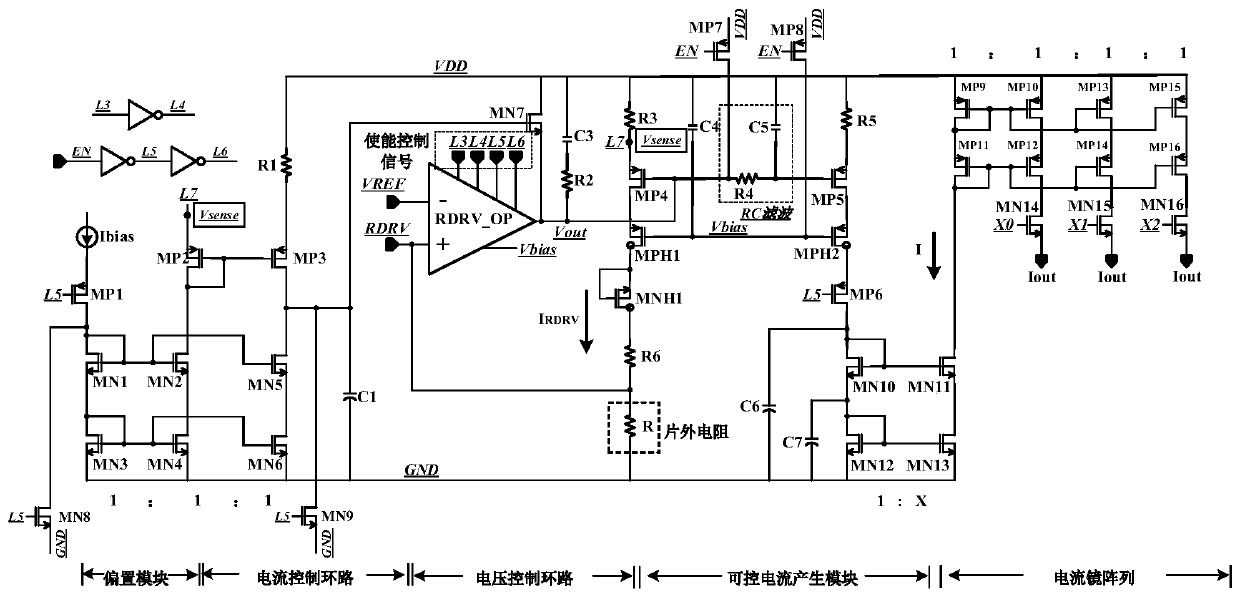

[0055] Such as figure 2 Shown is the gate drive current charging circuit of the power device proposed by the present invention. In this embodiment, the charging circuit is applied to the low-side power device, and its power rail is VDD-GND. The charging circuit is actually a maximum current clamp The on-chip adjustable current source circuit includes an off-chip resistor R, a bias module, a current control loop, a voltage control loop, a controllable current generation module and a current mirror array. The bias module is used to generate the first bias voltage and the second bias voltage, such as figure 2 The figure shows an implementation form of the bias module, including the first PMOS transistor MP1, the first NMOS transistor MN1, the third NMOS transistor MN3 and the eighth NMOS transistor MN8, the source of the first PMOS transistor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com