A Balanced Two-position Three-way Fuel Injection Valve

A fuel injection valve, two-position three-way technology, used in fuel injection devices, fuel injection valves driven by fluid pressure, special fuel injection devices, etc., can solve problems such as reducing dynamic oil return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

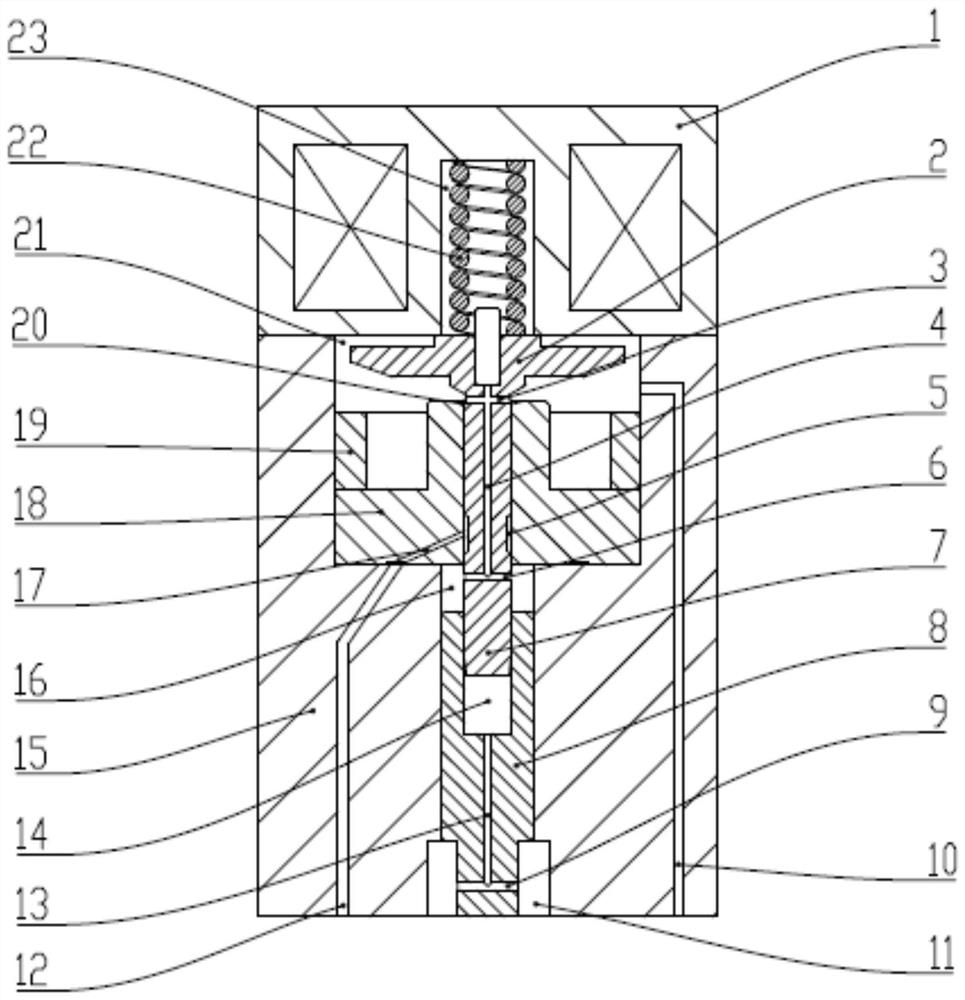

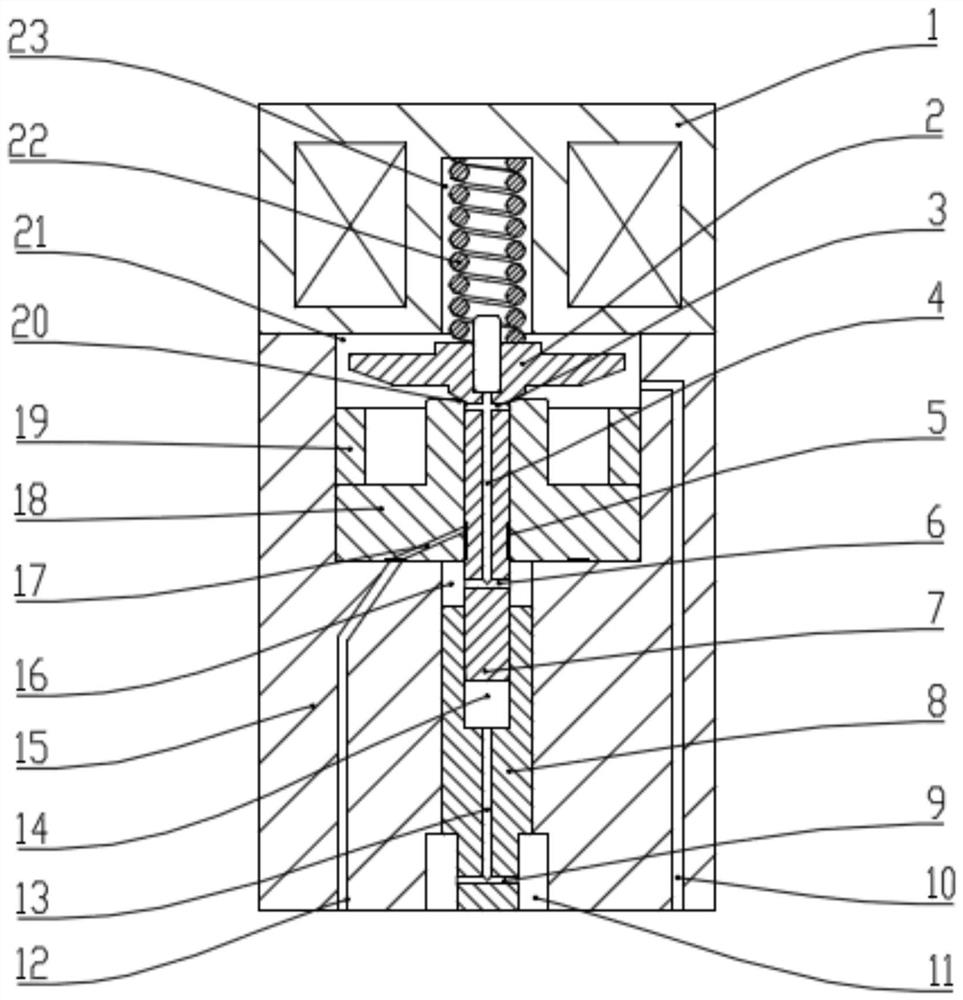

[0022] Such as figure 1 Shown in -3, the present invention mainly comprises armature 2, armature rod 7, control valve seat 18, control valve seat fixing nut 19, injector body 15, control piston 8, electromagnet 1, electromagnet spring 22.

[0023] The control valve seat 18 is pressed into the concave cavity on the upper part of the injector body 15 through the control valve seat fixing nut 19. The control valve seat 18 is provided with an oil inlet orifice 17, and one end of the hole passes through the lower part of the control valve seat. The annular groove 24 communicates with the oil inlet passage 12 on the injector body 15 , and the other end communicates with the middle hole of the control valve seat 18 .

[0024] The armature 2 and the armature rod 7 are integrally structured, and the armature rod 7 extends into the middle hole of the control valve seat 18 and can slide axially along the middle hole. The electromagnet center is provided with an electromagnet middle hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com