A shutter for adjusting temperature and its preparation method

A technology for adjusting temperature and shutters, applied in chemical instruments and methods, windows/doors, materials for heat exchange, etc., can solve the problems of high cost and poor temperature adjustment effect, achieve convenient operation, reduce energy consumption, and save raw materials cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

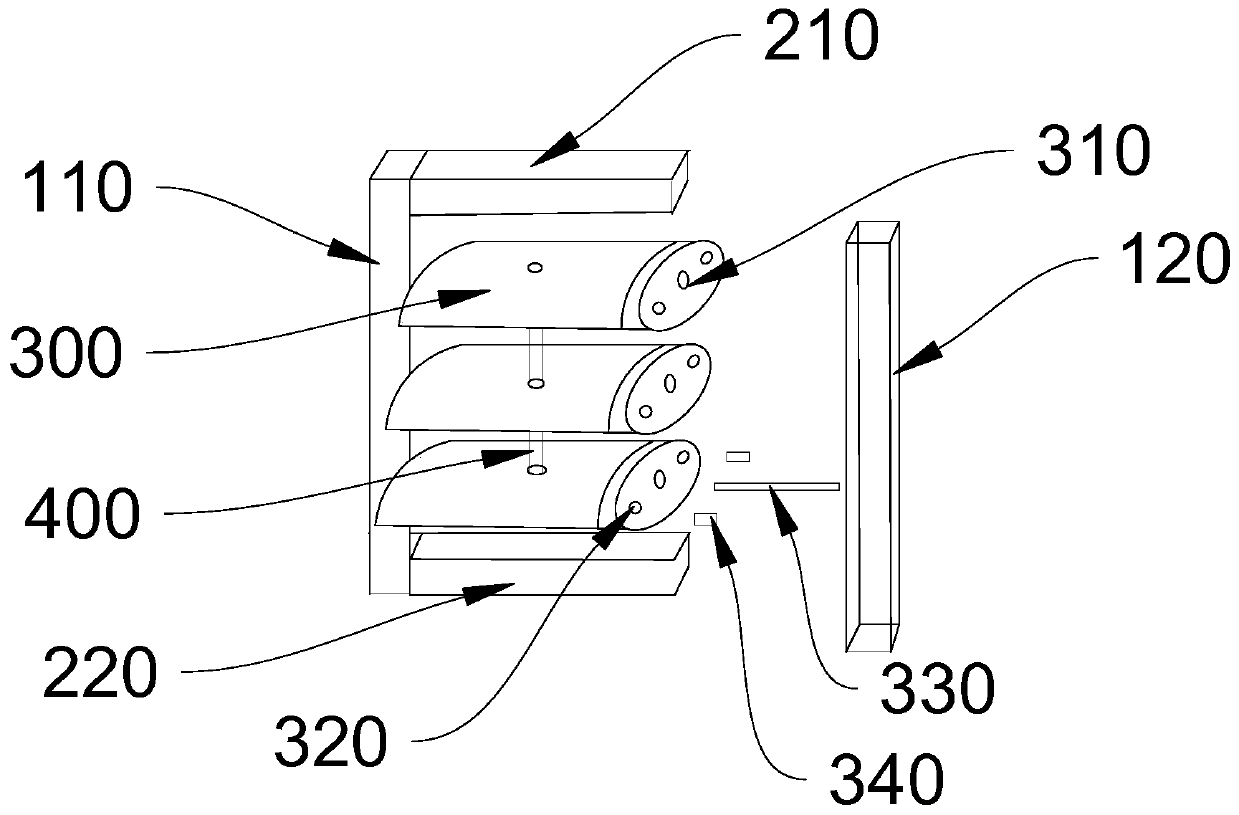

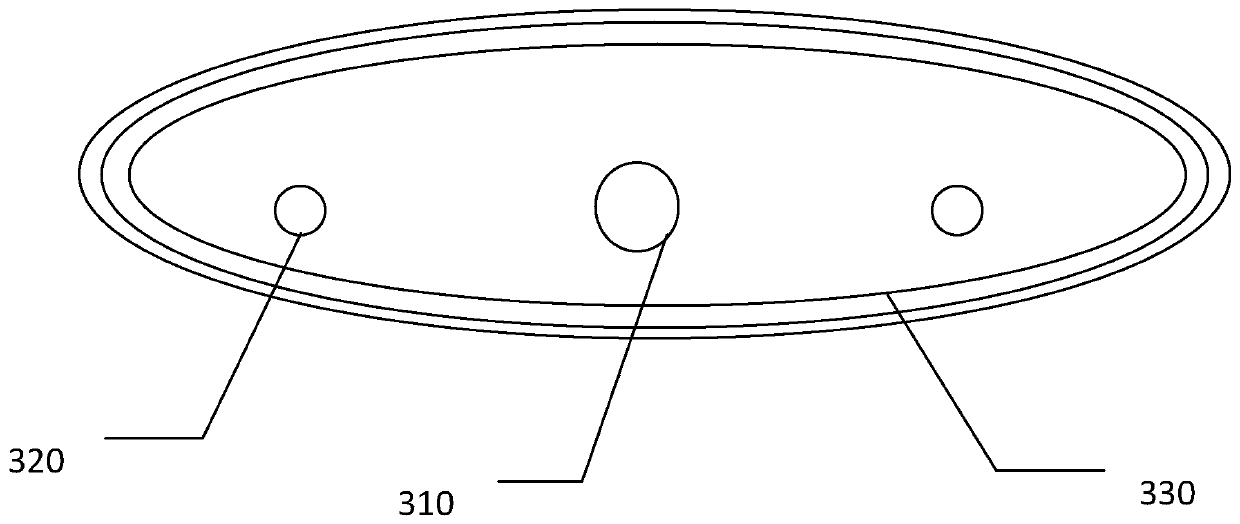

[0032] Cooperate figure 1 As shown, the louver for adjusting temperature provided by the embodiment of the present invention includes a plurality of fixedly connected blades, wherein the blades are filled with composite shaped phase change materials made of organic phase change materials and inorganic support materials. The composite shaped phase change material is composed of organic phase change materials and inorganic support materials with different mass ratios. Wherein, the louver blade is a hollow structure, and the preparation material of the blade includes aluminum or copper.

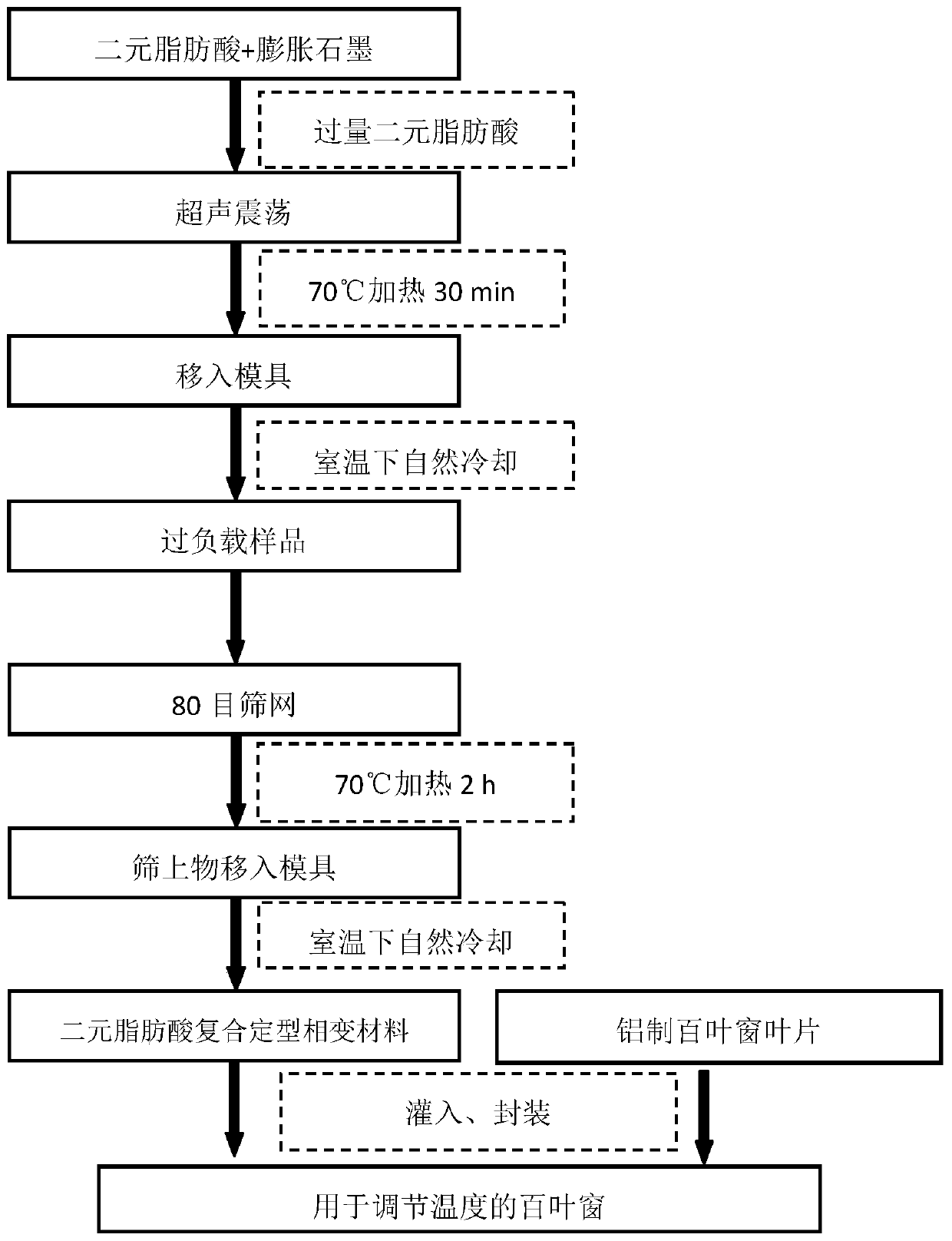

[0033] Wherein, the manufacturing method of the composite shaped phase change material according to the embodiment of the present invention includes the following steps:

[0034] Preparation materials: organic phase change materials stearic acid and capric acid; inorganic support materials use expanded graphite.

[0035] Preparation of composite shaped phase change material: Weigh stearic acid...

Embodiment 2

[0038] In the embodiment of the present invention, the prepared dibasic fatty acid phase change material, in which 15.00 kg of stearic acid, 5.00 kg of capric acid and 0.10 kg of inorganic support material expanded graphite were evenly mixed, heated at 70°C under ultrasonic vibration After 30 minutes, the mixed material was poured into the mold and cooled naturally at room temperature to obtain an overloaded dibasic fatty acid composite phase change material. Put the overloaded dibasic fatty acid composite phase change material on the 80-mesh screen, and heat it at 70°C for 2 hours, so that the unadsorbed phase change energy storage material flows down the screen, and the composite phase change material on the screen is removed. Cool naturally to room temperature in the mold to prepare the dibasic fatty acid composite shaped phase change material. The prepared dibasic fatty acid composite shape-changing material is poured into the hollow part of the aluminum louver blade and p...

Embodiment 3

[0040] In the embodiment of the present invention, 10.00 kg of dibasic fatty acid phase change materials stearic acid, 10.00 kg of capric acid and 0.10 kg of organic support material expanded graphite were uniformly mixed, heated at 70°C for 30 minutes under ultrasonic vibration, and the mixed material Pour into a mold and cool naturally at room temperature to prepare an overloaded dibasic fatty acid composite phase change material. Put the overloaded dibasic fatty acid composite phase change energy storage material on the 80-mesh screen, heat it at 70°C for 2 hours, let the unadsorbed composite phase change material flow down the screen, and take the composite phase change material on the screen Moved to the mold and naturally cooled to room temperature, the dibasic fatty acid composite shaped phase change material was obtained. The prepared dibasic fatty acid composite shape-changing material is poured into the hollow part of the aluminum louver blade and packaged to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com