Intelligent source reduction complete technology method for high-lead anode mud heavy metal pollutants

A technology for anode slime and pollutants, applied in electrodes, electrolytic processes, electrolytic components, etc., can solve the problem of rising lead content in products, the inability to accurately identify the thickness of lead-based film and anode slime and the change of lead elements, anode slime Increase and other issues, to achieve the effect of improving the economic benefits of the enterprise, inhibiting the dissolution of lead, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

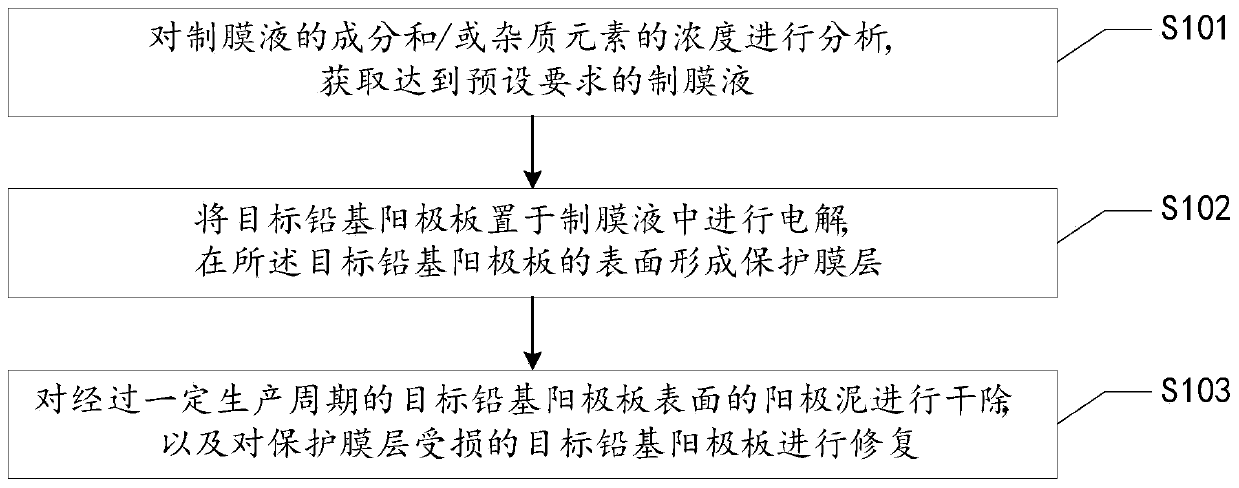

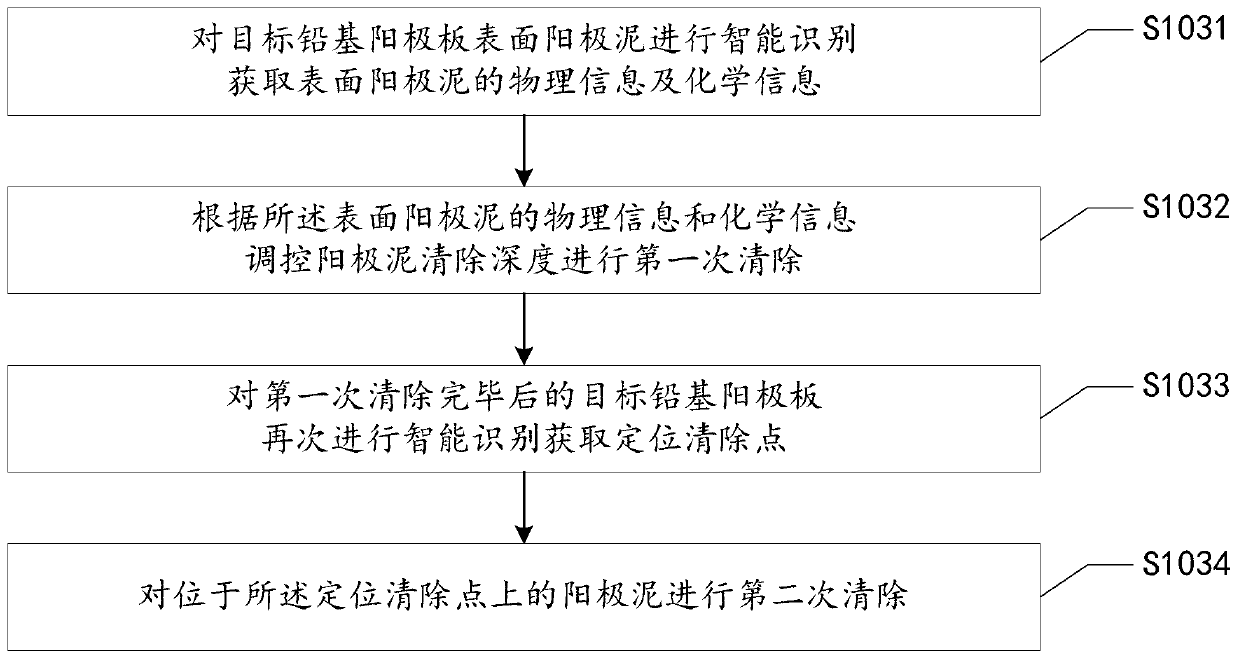

[0056] Such as figure 1 and figure 2 As shown, this embodiment proposes a complete set of technical methods for intelligent source reduction of heavy metal pollutants in high-lead anode sludge, and the method includes:

[0057] S101. Analyzing the composition of the film-forming solution and / or the concentration of impurity elements to obtain a film-forming solution that meets preset requirements.

[0058] Specifically, in this embodiment, the film-forming solution is firstly analyzed using optical principles. The content of the analysis may include the composition of the film-forming solution and the concentration of impurity elements, etc., so as to timely grasp the concentration of acid, manganese, lead, etc. in the film-forming solution. information. The analysis results are obtained after analyzing the film-making liquid, and then the analysis results are compared with the production indicators to make a film-making liquid that meets the production requirements.

[00...

Embodiment 2

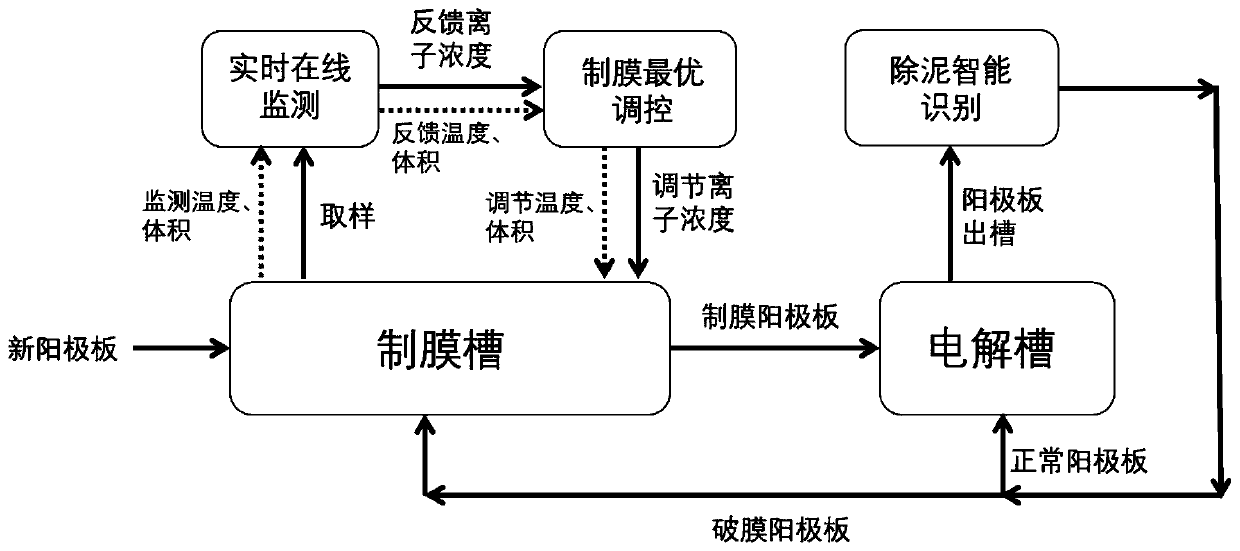

[0078] Such as Figure 4 As shown, this embodiment proposes a complete set of technical methods for intelligent source reduction of heavy metal pollutants in high-lead anode slime. The implementation of the complete set of technical methods includes a real-time online monitoring device 6, an optimal control device for film production, and intelligent non-destructive deslagging device 10;

[0079] The real-time online monitoring device 6 is used to analyze the composition of the film-forming liquid and / or the concentration of impurity elements to obtain the film-forming liquid that meets the preset requirements; and place the target lead-based anode plate in the film-forming liquid Carry out electrolysis, while forming a protective film layer on the surface of the target lead-based anode plate, analyze the composition and / or concentration of impurity elements of the film-forming solution, and control the composition and / or impurities of the film-forming solution The concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com