Method for observing blast furnace coal injection condition

A technology of blast furnace coal injection and blast furnace, applied in blast furnace, blast furnace details, furnace, etc., can solve problems such as limited use value, unfavorable installation and use of active cameras, and large interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention is described in further detail:

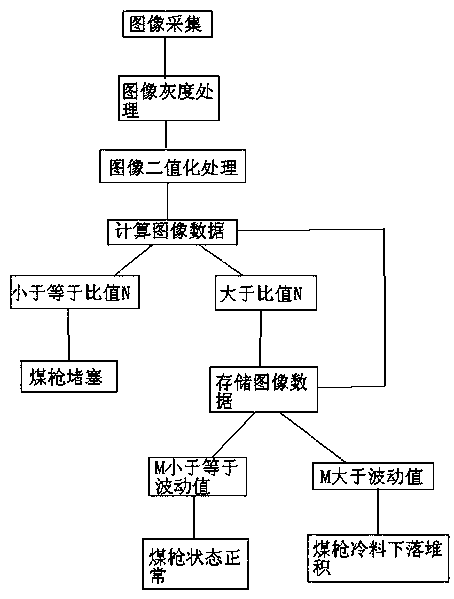

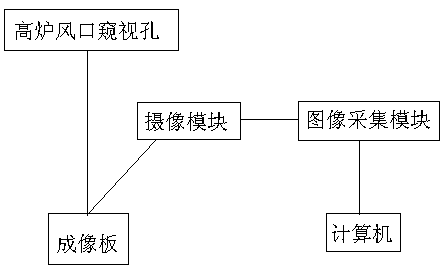

[0015] Such as figure 1 and figure 2 Shown, a kind of method of observing blast furnace coal injection situation, described method comprises:

[0016] In step a, an imaging plate facing the peephole of the tuyere of the blast furnace is set up outside the peephole of the tuyere of the blast furnace;

[0017] In step b, the camera module and the imaging board are arranged at an angle between the peep hole of the blast furnace tuyere and the imaging board, and the camera module records the image on the imaging board, and transmits the image to the image acquisition module; in step c, the image acquisition module converts the image is a grayscale image; step d converts the grayscale image into a coal injection image by binarizing the grayscale image, the coal mass in the coal injection image is represented by black, and the rest is represented by white; step e calculates the rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com