Graphene modified polyurethane foam and preparation method thereof

A polyurethane foam and graphene modification technology, which is applied in the field of polyurethane foam, can solve the problems of polyurethane foam and other problems, achieve good mechanical properties and improve the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

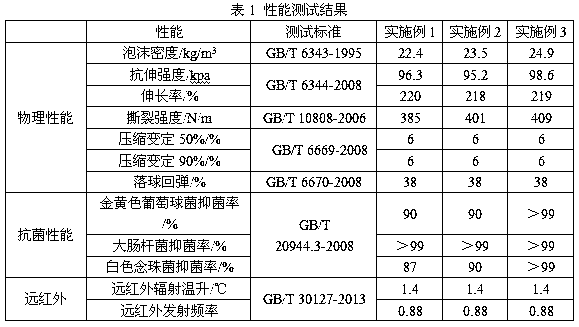

Examples

preparation example Construction

[0026] The preparation method of this graphene-modified polyurethane foam adopts the method of in-situ polymerization, which is different from the method of direct addition such as blending. Specifically: graphene is functionalized graphene with isocyanate groups, and isocyanate-functionalized graphene It is prepared by modifying graphene oxide;

[0027] Graphene-modified polyurethane foam is formed by reacting isocyanate, isocyanate-modified graphene, polyether polyol, chain extender, foaming agent, catalyst, and silicone foam stabilizer under certain conditions;

[0028] The mass of graphene accounts for 0.05%-0.3% of the mass of isocyanate.

[0029] The preparation method of graphene modified polyurethane foam, the concrete steps of this preparation method comprise:

[0030] The first step, preparation of isocyanate functionalized graphene

[0031] Add the graphene powder into the solvent for dispersion;

[0032] Then add TDI, react at a temperature of 80-100°C, and the ...

Embodiment 1

[0049] The first step, preparation of isocyanate functionalized graphene

[0050] Weigh 1g of graphene oxide, add 50g of dehydrated xylene, after ultrasonication for 0.5h, add 10g of TDI, and react at a temperature of 95°C for 6h;

[0051] After the reaction was completed, wash and suction filter three times with dehydrated toluene;

[0052] Then dry in a vacuum oven at 80° C. to obtain gray ultrafine powder of isocyanate-functionalized graphene.

[0053] The second step, the preparation of graphene modified polyurethane foam

[0054] Take 46g of TDI, add 0.1g of isocyanate functionalized graphene, ultrasonic and strong shear dispersion for 0.5h;

[0055] According to the soft foam formula, take 100g of polyether polyol, 0.4g of organotin catalyst, 0.2g of tertiary amine catalyst, 1g of silicone foam stabilizer, 3g of water, and 1g of auxiliary foaming agent. After stirring rapidly, pour it into the mold to obtain polyurethane foam block bubbles.

Embodiment 2

[0057] The first step, preparation of isocyanate functionalized graphene

[0058] Weigh 2g of graphene oxide, add 50g of dehydrated xylene, after ultrasonication for 0.5h, add 5g of TDI, and react at 95°C for 6h;

[0059] After the reaction was completed, wash and suction filter three times with dehydrated toluene;

[0060] Then dry in a vacuum oven at 80°C to obtain gray ultrafine powder of isocyanate-functionalized graphene.

[0061] The second step, the preparation of graphene modified polyurethane foam

[0062] Take 46g of TDI, add 0.3g of isocyanate functionalized graphene, ultrasonic and strong shear dispersion for 0.5h;

[0063]According to the soft foam formula, take 100g of polyether polyol, 0.4g of organotin catalyst, 0.2g of tertiary amine catalyst, 1g of silicone foam stabilizer, 3g of water, and 3g of auxiliary foaming agent. After stirring rapidly, pour it into the mold to obtain polyurethane foam block bubbles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com