Lithium-aluminosilicate glass, lithium-aluminosilicate chemically strengthened glass and preparation method and application thereof

A lithium-aluminum-silicon and glass technology, applied in the field of glass products, can solve the problems that the compressive stress cannot be effectively balanced, and the strength and anti-drop performance are neglected, so as to achieve good ion exchange characteristics, excellent strength and anti-drop performance, improve Yang The effect of the modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

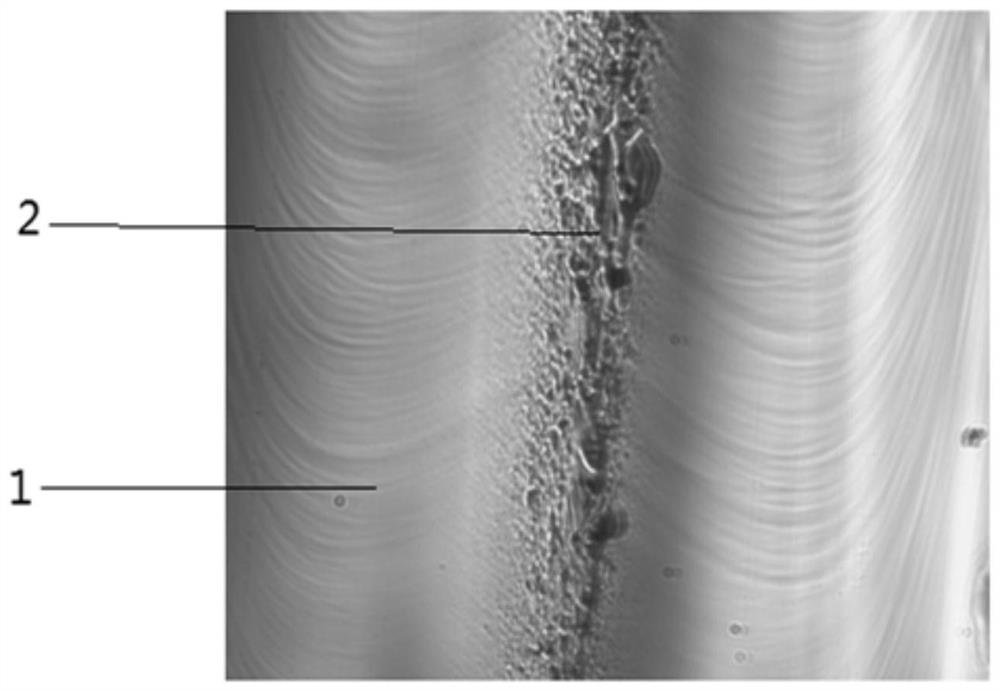

Image

Examples

preparation example Construction

[0090] Meanwhile, based on the lithium aluminum silicon glass described above, the embodiment of the present invention also provides a preparation method of the above lithium aluminum silicon chemically strengthened glass. The preparation method of the lithium aluminum silicon chemically strengthened glass comprises the following steps:

[0091] The plain glass to be chemically strengthened is subjected to multi-step binary ion exchange or single-step binary ion exchange treatment in a monovalent metal nitrate bath.

[0092] Wherein, the plain glass to be chemically strengthened is the above-mentioned lithium aluminum silicate glass. Since the lithium-aluminosilicate glass, that is, the plain glass contains high silicon and aluminum and high magnesium content, specifically, the components contained in the plain glass to be chemically strengthened and each component are preferably as described above Plain glass, in order to save space, the components and contents of the above-...

Embodiment 11-16

[0112] Embodiments 11-16 respectively provide a lithium aluminum silicate glass. Based on the total amount of components contained in the lithium-aluminosilicate glass as 100 mol%, the components contained in the lithium-aluminosilicate glass in each example are shown in Table 1 below.

[0113] The lithium-aluminosilicate glasses provided in Examples 11-16 were mixed according to the recipes in Table 1, and the mixed materials were put into platinum crucibles, and melted at 1650° C. for 5 hours in a high-temperature lifting furnace, and then Pouring in a preheated stainless steel mold, then putting it into an annealing furnace, and performing a long-term gradient annealing around the annealing point to eliminate the internal stress of the lithium-aluminosilicate glass. After the annealing is completed, the lithium-aluminosilicate glass bricks are cut on the six sides to obtain lithium-aluminosilicate glass bricks of appropriate size, which are then cut, flat-ground, and swept by...

Embodiment 21-26

[0122] Examples 21-26 respectively provide a lithium aluminum silicon chemically strengthened glass and a preparation method thereof. The relevant properties of each of the lithium aluminum silicon chemically strengthened glasses and the chemical strengthening treatment steps and relevant process parameters of the preparation method are described in Table 2 below.

[0123] The relevant mechanical properties of the chemically strengthened glass provided by each example are also shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com