Yogurt fermentation method

A fermentation method and yogurt technology, applied to milk preparations, bacteria used in food preparation, and other dairy products, can solve the problems of single type and structure, weak basic research, etc., and achieve the reduction of whey precipitation rate and excellent quality , Improve the effect of nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

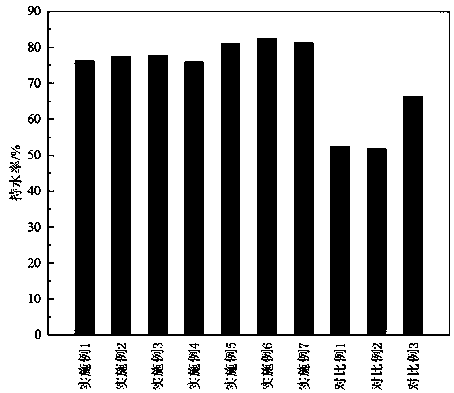

Examples

Embodiment 1

[0017] A method for fermenting yogurt, the steps comprising:

[0018] (1) To prepare the extract of asparagus-Russia japonica-fish bone meal, mix the fresh asparagus japonica and the fruit of asparagus japonica according to the mass ratio of asparagus japonica:Russia japonica fruit=10:1, and then mix them at 100-110°C Dry for 3 hours. After drying, mash asparagus and thorn rose and put them in an airtight container. Fill the container with air until the air pressure in the container reaches 2 standard atmospheric pressure, keep the pressure for 30 minutes, and then quickly evacuate to 0.3 Atmospheric pressure, hold the pressure for 10 minutes, balance the air pressure inside and outside the container after holding the pressure, take out the asparagus and thorn rose; then mix the asparagus, thorn rose and fish bone meal in a mass ratio of 10:1:3 , soak the mixed mixture in an aqueous solution of citric acid with a mass percentage of solute of 2%, incubate at 40±10°C for 1 hour,...

Embodiment 2

[0022] A method for fermenting yogurt, the steps comprising:

[0023] (1) To prepare the extract of asparagus-Russia japonica-fish bone meal, mix the fresh asparagus and japonica japonica fruit according to the mass ratio of asparagus japonica: japonica japonica fruit=10:1.3 and then mix them at 100~110°C Dry for 4 hours. After drying, mash asparagus and thorn rose and put them in a closed container. Fill the container with air until the air pressure in the container reaches 2 standard atmospheric pressure, keep the pressure for 40 minutes, and then quickly evacuate to 0.3 Atmospheric pressure, keep the pressure for 10 minutes, balance the pressure inside and outside the container after the pressure keeping, take out the asparagus and thorn rose; then mix the asparagus, thorn rose and fish bone meal according to the mass ratio of 10:1.3:3.7 , soak the mixed mixture in an aqueous solution of citric acid with a mass percentage of solute of 3%, incubate at 40±10°C for 1 hour, cen...

Embodiment 3

[0027] A method for fermenting yogurt, the steps comprising:

[0028] (1) To prepare the extract of asparagus-Russia japonica-fish bone meal, mix the fresh asparagus and jasmine asparagus fruit according to the mass ratio of asparagus asparagus: asparagus japonica fruit=10:1.7, and then mix them at 100~110°C Dry for 4 hours. After drying, mash asparagus and thorn rose and put them in a closed container. Fill the container with air until the air pressure in the container reaches 2 standard atmospheric pressure, keep the pressure for 50 minutes, and then quickly evacuate to 0.3 Atmospheric pressure, keep the pressure for 20 minutes, balance the pressure inside and outside the container after the pressure keeping, take out the asparagus and thorn rose; then mix the asparagus, thorn rose and fish bone meal according to the mass ratio of 10:1.7:4.2 , soak the mixed mixture in an aqueous solution of citric acid with a solute mass percentage of 3%, heat it at 40±10°C for 2 hours, cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com