A Collinear Mixing Frequency Ultrasonic Detection Method for Mechanical Performance Degradation of Tank Torsion Shaft

A technology of ultrasonic testing and torsion axis, applied in the direction of measuring devices, scientific instruments, strength characteristics, etc., can solve the problems that the fatigue life prediction work of military equipment has not yet been carried out, and achieve the effects of eliminating interference, suppressing nonlinearity, and effectively extracting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

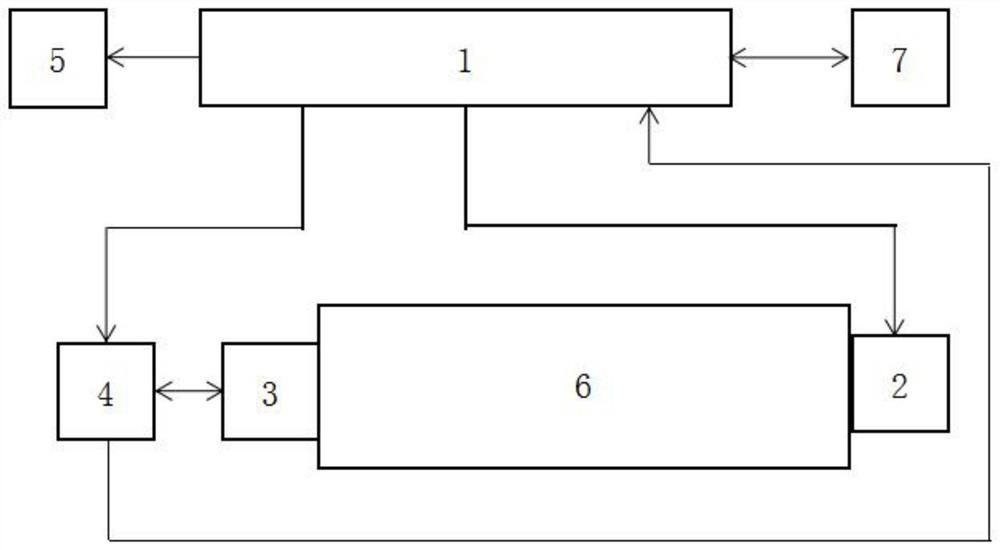

[0046] The following combination figure 1 To illustrate the specific implementation process, a detection system for detecting the degradation of the mechanical properties of the torsion shaft of a tank based on collinear mixed-frequency nonlinear ultrasonic testing, the detection system includes: a nonlinear high-energy ultrasonic system 1, a longitudinal wave ultrasonic transducer 2, a transverse wave ultrasonic transducer Energy device 3, duplexer 4, digital signal oscilloscope 5, torsional fatigue test piece 6, computer 7 and data transmission line. The signal output end of the nonlinear high-energy ultrasonic system 1 is respectively connected to the longitudinal wave ultrasonic transducer 2 and the duplexer 4 through a data transmission line, the duplexer 4 and the transverse wave ultrasonic transducer 3 are connected through a data transmission line, and the longitudinal wave ultrasonic transducer The transducer 2 and the shear wave ultrasonic transducer 3 are vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com