Electronically controlled hydraulic slottingblocking-removing reservoir modification tool

A technology of reservoir stimulation and electronically controlled hydraulic pressure, which is applied in the direction of cleaning equipment, liquid/gas jet drilling, wellbore/well components, etc., can solve the problems of perforation compaction zone pollution, insufficient perforation depth, etc. Controllable, reduced bursting pressure, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

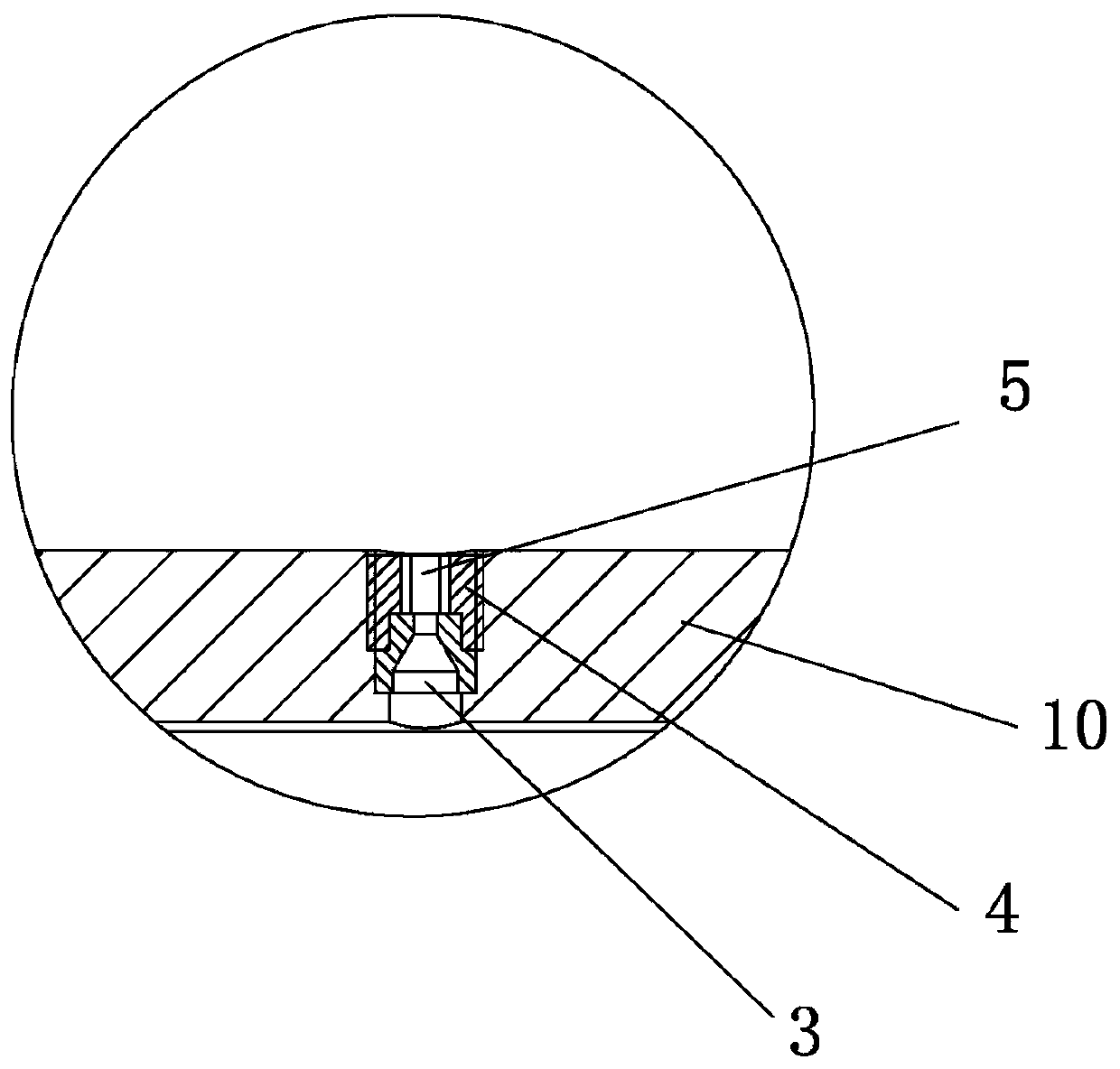

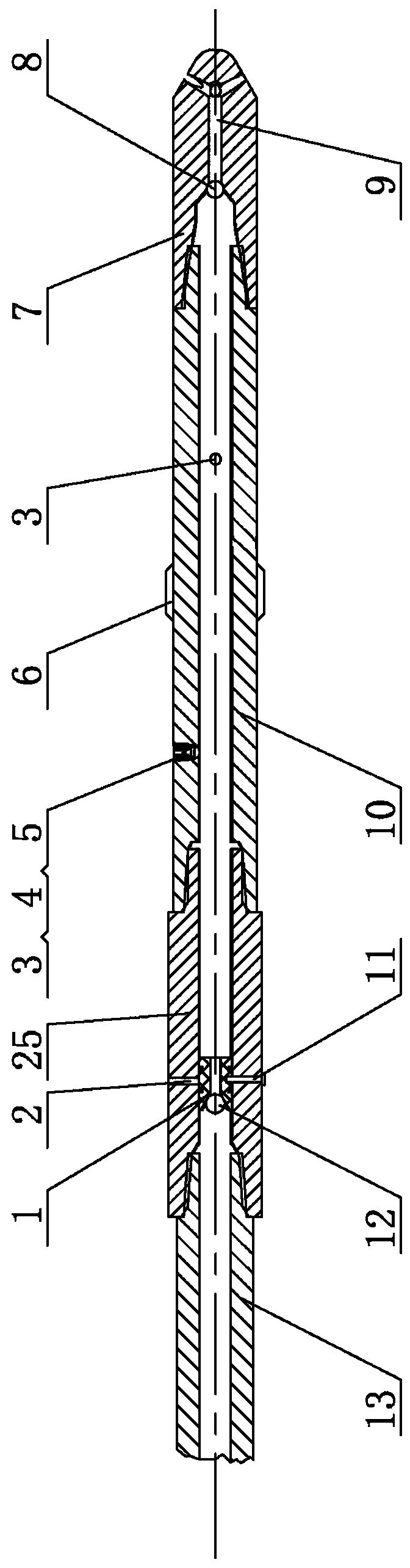

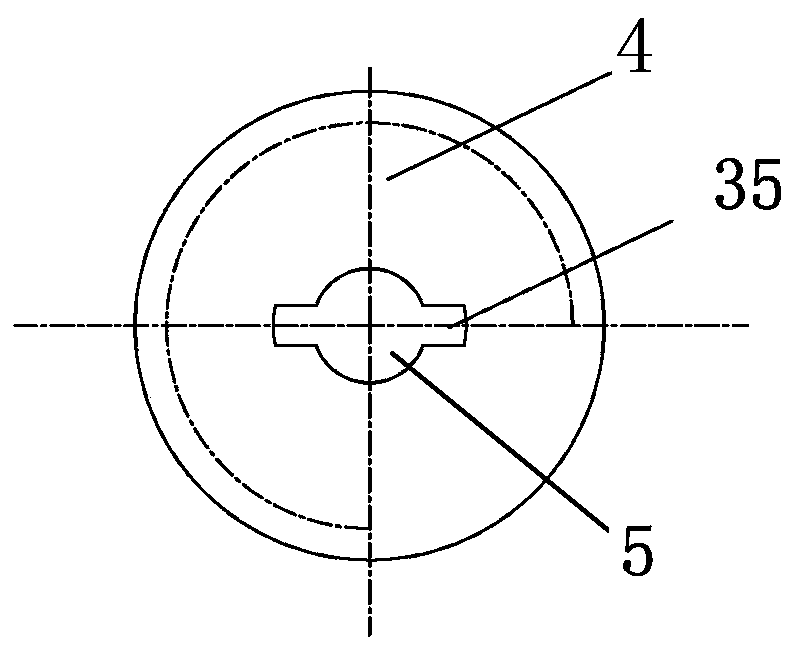

[0020] An electronically controlled hydraulic slotting and plugging removal reservoir reconstruction tool, such as figure 1 , figure 2 , image 3 As shown, it includes a reservoir stimulation valve connected to the oil pipe 13. The reservoir stimulation valve includes a casing valve seat 25, and the center hole of the casing valve seat 25 is fixedly set by a shear nail 11 perpendicular to the casing valve seat. Along with a sliding sleeve 1, the pressure relief hole 2 arranged coaxially with the shear nail is located in the pipe wall on the other side of the central hole of the sleeve valve seat, and the center of the sliding sleeve has a central through hole arranged coaxially with the central hole of the sleeve valve seat , the outer end surface of the sliding sleeve near the oil pipe is recessed and a bakelite ball 12 is housed, and the diameter of the bakelite ball 12 is greater than the aperture of the central through hole.

[0021] The lower end of the casing valve se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com