Method for resuming production and unsealing of sealed gas wells

A technology for unblocking and gas wells, which is applied in earthwork drilling, flushing wellbore, wellbore/well components, etc. It can solve problems such as low pressure coefficient of low-pressure gas wells, poor plugging removal effect, and inability to remove viscous materials, etc., to achieve improvement Reservoir seepage conditions, improving production capacity, and preventing gas wells from blowing out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

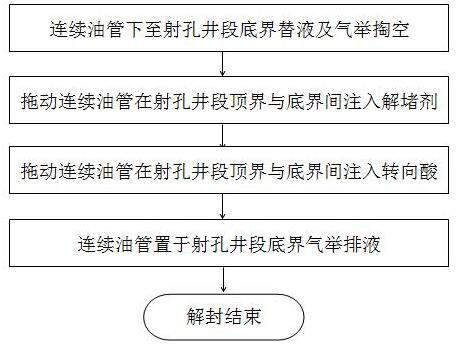

[0035] The invention discloses a method for resuming production and unsealing a sealed gas well, which comprises the following steps:

[0036] Step 1. Coiled tubing hollowing out for liquid and gas lift

[0037] Lower the coiled tubing to the bottom boundary of the perforated well section, pump cleaning fluid into the coiled tubing to clean the coiled tubing and replace the killing fluid out of the wellhead. The cleaning fluid is preferably diesel oil; then inject nitrogen to clean the cleaning fluid in the wellbore. Empty, the depth of hollowing out until the pressure generated by the remaining liquid column in the wellbore is 10% higher than the formation pressure.

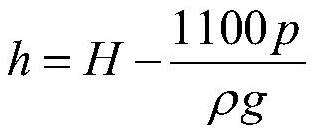

[0038] In this step, the calculation method of hollowing depth is:

[0039]

[0040] In the formula: h - hollowing out depth, refers to the height between the wellhead and the liquid level in the wellbore, in m;

[0041] H—well depth in the middle of the reservoir, unit m;

[0042] p—formation pressure, un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com