Metal material and metal material surface in-situ dissolution modification method

A metal material modification technology, applied in metal material coating technology, metal processing equipment, chemical instruments and methods, etc., can solve problems such as metal material surface modification, achieve improved catalytic performance, wide application range, and commercialization significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An embodiment of the metal material described in the present invention, the metal material described in this embodiment is prepared by the following method:

[0036] Weigh 287.5g metallic Ni powder as the base metal powder, weigh 25g metallic Ag powder as the modified metal powder, and the mass fraction of the modified metal powder is 8%. Move the weighed powder into the V-shaped mixer, and in 10r min -1 Mix for 24 hours under the condition of the speed of rotation, make it fully mixed, and use it as a raw material powder. The above-mentioned raw material powders will be used to prepare coated catalysts using atmospheric plasma spraying equipment (APS). Prepare the coating catalyst in 20ml min -1 Under the protection of hydrogen, the temperature was raised to 800°C and held for 4 hours and 8 hours respectively. After the sintering procedure was completed, the quartz tube was opened to take out the sample, and the in-situ eluted modified metal material was obtained.

...

Embodiment 2

[0039] An embodiment of the metal material described in the present invention, the metal material described in this embodiment is prepared by the following method:

[0040] Take by weighing 475g metal Ni powder as base metal powder, take by weighing 25g metal Ag powder as modified metal powder, the modified metal powder mass fraction is 5%; 400r min -1 Mix for 6 hours under the condition of a certain speed, make it fully mixed, and then dry it in an oven as a raw material powder for use; use the above raw material powder to prepare a coating catalyst by using a cold spraying equipment (CS); seal the prepared coating catalyst into a quartz tube evacuated at room temperature and backfilled with 300mbar of argon; the sealed quartz tube was heated to 800°C in a muffle furnace and kept warm for 4h and 8h respectively. Dissolution of modified metal materials.

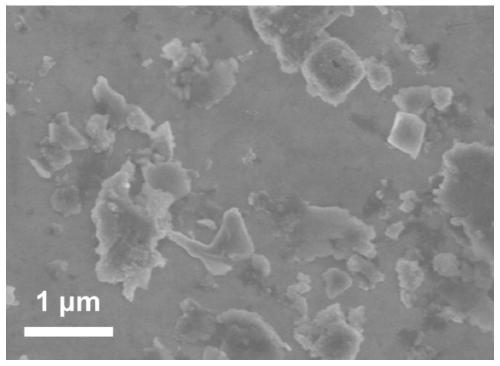

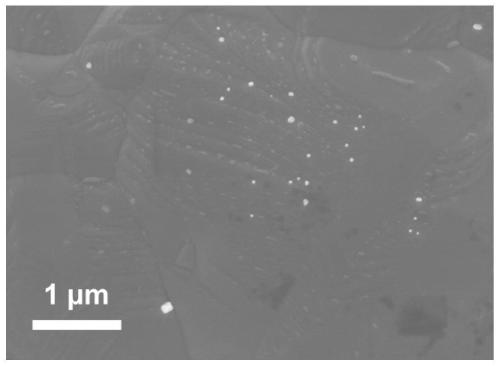

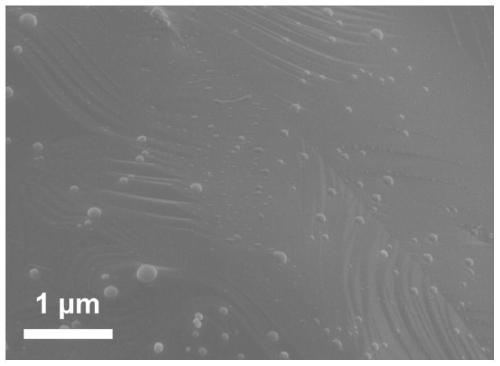

[0041] During the preparation process, SEM tests were carried out on the surfaces of the original coated catalyst without h...

Embodiment 3

[0043] An embodiment of the metal material described in the present invention, the metal material described in this embodiment is prepared by the following method:

[0044] Weigh 499.5g metal Fe powder as the base metal powder, weigh 0.5g metal Au powder as the modified metal powder, and the mass fraction of the modified metal powder is 0.1%; move the weighed powder into a ball mill jar, and use water as a dispersant , at 400rmin -1 Mix for 6 hours under the condition of the rotating speed of 6h to make it fully mixed, and then dry it in the oven as a raw material powder for use; the above raw material powder will be prepared by atmospheric plasma spraying to prepare a coating catalyst; the prepared coating catalyst will be sealed in a quartz tube, room temperature Pump down to vacuum and backfill with 300mbar argon; heat the sealed quartz tube to 500°C in a muffle furnace and keep it warm for 8h and 12h respectively. After the sintering process, open the quartz tube and take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com