Fluorescent silicone sealant for glass decoration and preparation method of fluorescent silicone sealant

A silicone sealant, fluorescent technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor transparency, the inability of silicone sealants to meet the requirements, and the inability to meet the requirements for glass decoration purposes. , to achieve the effect of good water resistance, high adhesion and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

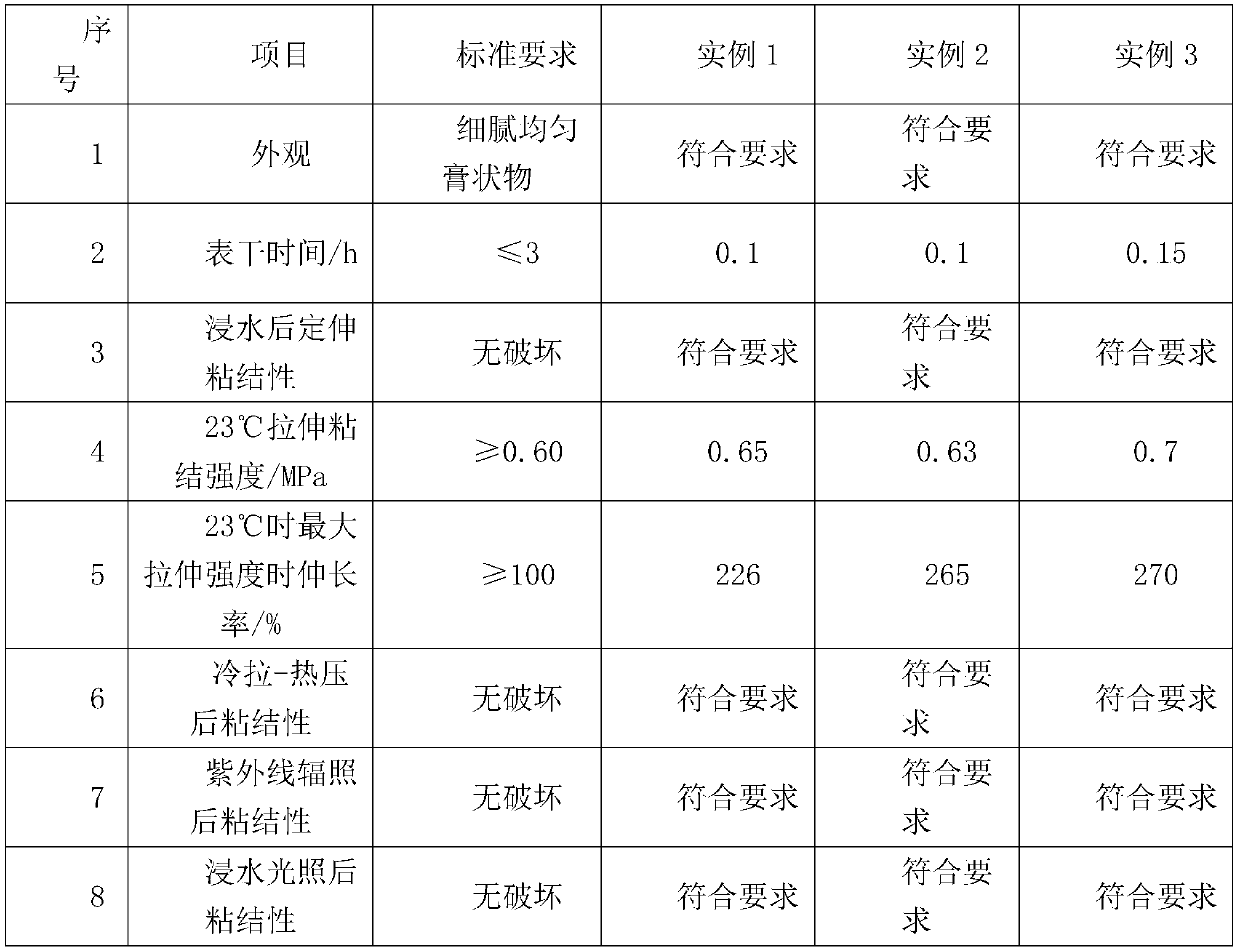

Embodiment 1

[0026] In the embodiment of the present invention, a fluorescent silicone sealant for glass decoration, with a transparency of 80% after bonding, includes the following raw materials in parts by weight: 90 parts of hydroxyl-terminated dimethylsiloxane, and 20 parts of plasticizer , 15 parts of silicon dioxide, 1 part of fluorescent powder, 8 parts of crosslinking agent, and 0.06 parts of catalyst.

[0027] The hydroxyl-terminated dimethylsiloxane is a mixture of 20 parts of hydroxyl-terminated dimethylsiloxane with a viscosity of 20000 Mpa.s and 70 parts of hydroxyl-terminated dimethylsiloxane with a viscosity of 80000 Mpa.s.

[0028] Described plasticizer is simethicone.

[0029] The silicon dioxide described above is silicon dioxide prepared by the gas phase method or silicon dioxide that has been activated during the gas phase method, and has a surface area of 80-220㎡ / g.

[0030] The fluorescent powder is a rare earth three primary color fluorescent powder.

[0031] The...

Embodiment 2

[0041] In the embodiment of the present invention, a fluorescent silicone sealant for glass decoration has a transparency of 79% after bonding, and includes the following raw materials in parts by weight: 90 parts of hydroxyl-terminated dimethylsiloxane, and 20 parts of plasticizer , 15 parts of silicon dioxide, 1 part of fluorescent powder, 8 parts of crosslinking agent, and 0.06 parts of catalyst.

[0042] The hydroxyl-terminated dimethylsiloxane is a mixture of 20 parts of hydroxyl-terminated dimethylsiloxane with a viscosity of 20000 Mpa.s and 70 parts of hydroxyl-terminated dimethylsiloxane with a viscosity of 80000 Mpa.s.

[0043] Described plasticizer is simethicone.

[0044] The silicon dioxide described above is silicon dioxide prepared by the gas phase method or silicon dioxide that has been activated during the gas phase method, and has a surface area of 80-220㎡ / g.

[0045] The fluorescent powder is a rare earth three primary color fluorescent powder.

[0046] T...

Embodiment 3

[0057] A fluorescent silicone sealant for glass decoration, characterized in that its transparency reaches 75%, including the following raw materials in parts by weight: hydroxy-terminated dimethylsiloxane: 109 parts, plasticizer: 23 parts; Silicon oxide: 22 parts; fluorescent powder: 1.5 parts; crosslinking agent: 7 parts; catalyst: 0.02 parts.

[0058] The viscosity of the hydroxyl-terminated dimethylsiloxane is 60000 Mpa.s.

[0059] The plasticizer is a mixture of white mineral oil and simethicone oil.

[0060] The silicon dioxide described above is silicon dioxide prepared by the gas phase method or silicon dioxide that has been activated during the gas phase method, and has a surface area of 200 m2 / g.

[0061] The fluorescent powder is a mixture of rare earth three-color fluorescent powder.

[0062] The crosslinking agent is a mixture of ethyl triacetoxysilane and propyl triacetoxysilane.

[0063] Described catalyzer is dibutyl tin diacetate.

[0064] The preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com