Yellowing-resistant and flame-retardant polyamide composition and preparation method thereof

A polyamide composition, flame retardant technology, applied in the field of anti-yellowing flame retardant polyamide composition and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

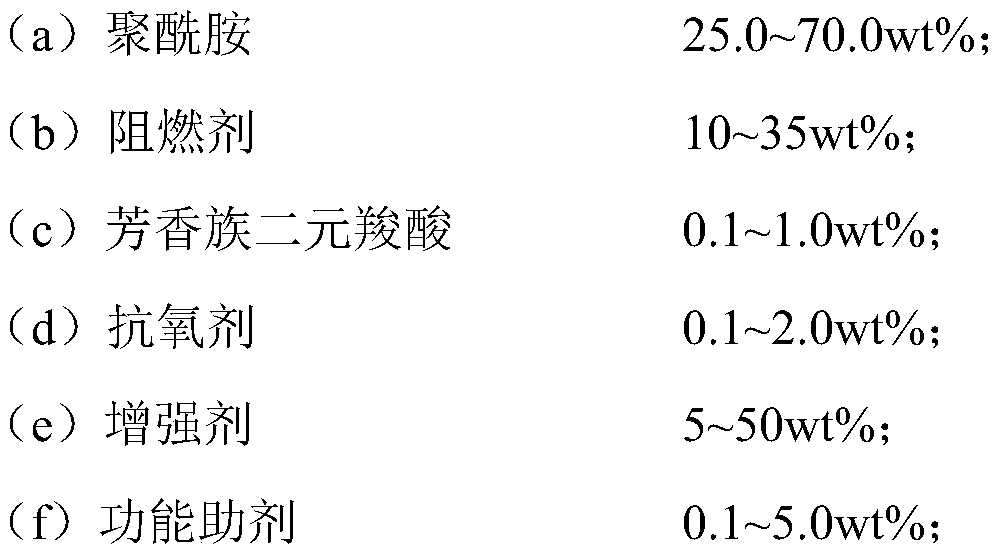

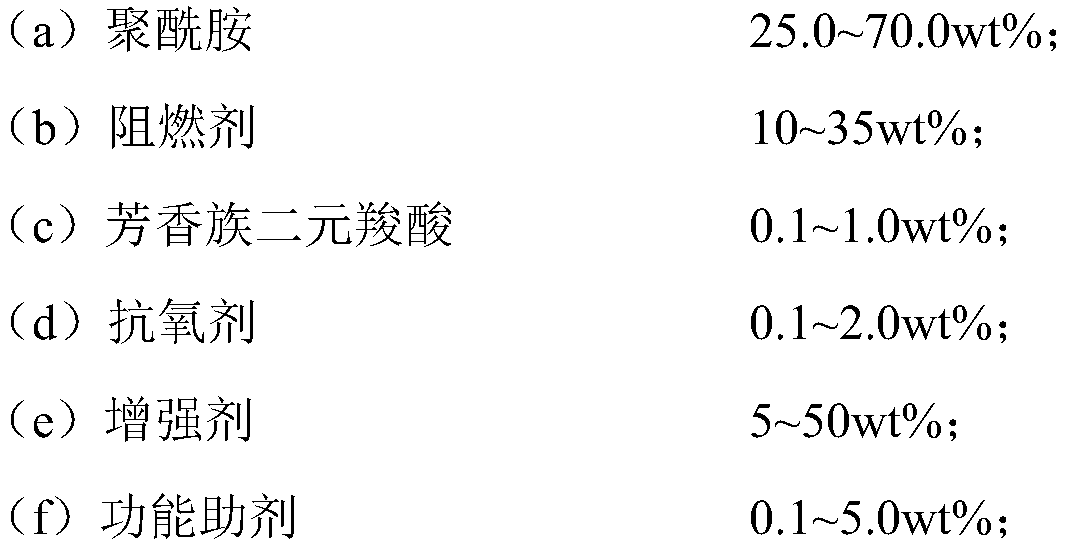

Method used

Image

Examples

Embodiment 1

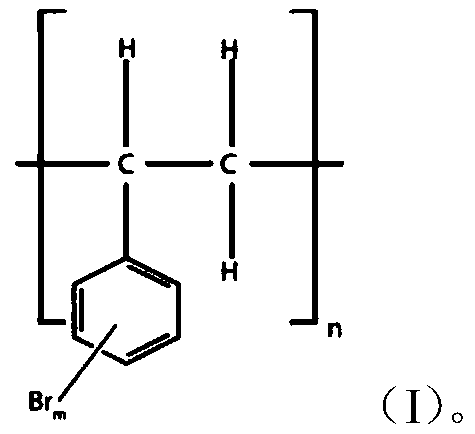

[0073] Example 1 and Comparative Example 1, it can be seen that the bromination (polystyrene) of the anionic PS substrate and the bromination (polystyrene) of the free radical PS substrate perform in terms of thermal yellowing resistance, and the bromination (polystyrene) of the anionic PS substrate Chemical (polystyrene) is obviously better than free radical PS matrix bromide (polystyrene), and it also shows that the heat stability of the flame-retardant polyamide composition is more difficult due to the flame-retardant component, and a suitable flame-retardant Agent selection is a necessary prerequisite.

[0074] In Examples 2 to 3 and Comparative Examples 2 to 3, it can be seen that the effect of aromatic dicarboxylic acid (2,6-naphthalene dicarboxylic acid) on stabilizing the polyamide composition, adding 2,6-naphthalene dicarboxylic acid The examples 2-3 of the examples 2-3 are significantly improved compared with the non-added comparative examples 2-3 regardless of short...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com