Long-carbon-chain nylon nano composite material and preparation method thereof

A nanocomposite material and nanomaterial technology, applied in the field of long carbon chain nylon nanocomposite materials and its preparation, can solve the problems of polyamide failing to enter the interlayer in time, product performance impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

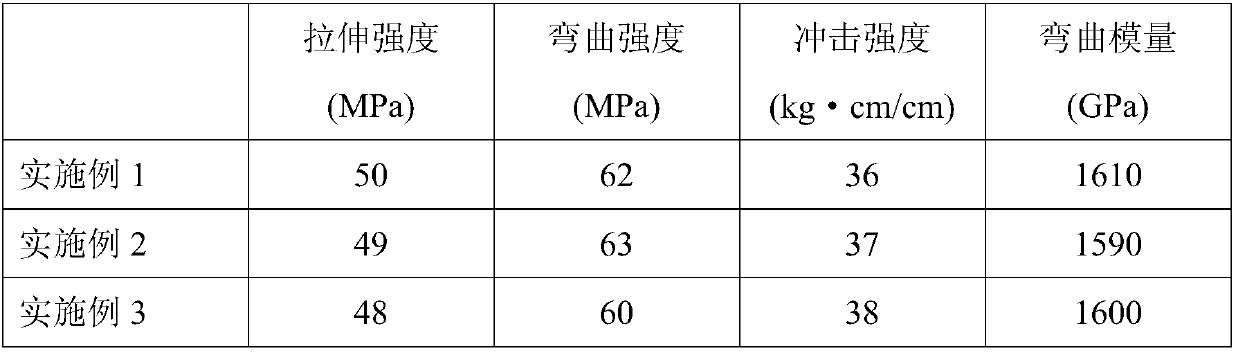

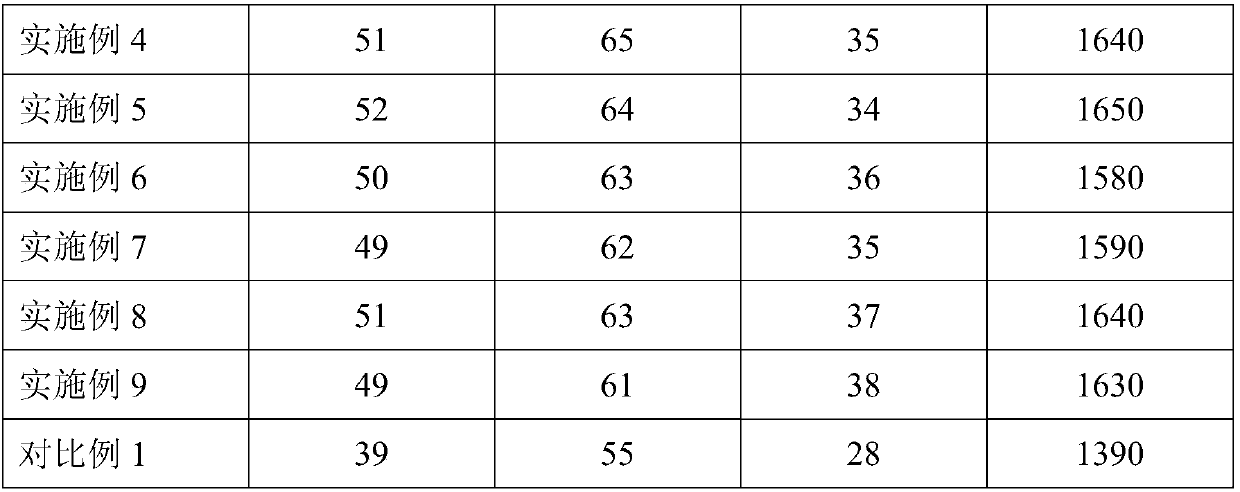

Examples

Embodiment 1

[0087] In this embodiment, the mass ratio of nanomaterials to long carbon chain nylon is 16:100, the long carbon chain nylon is selected from PA1010, the liquid medium used is water, the auxiliary agent used is o-dichlorobenzene, and the nanometer The material is a carbon nanotube, and the nanocomposite material is prepared according to the following method:

[0088] (1) Stir the liquid medium, and at the same time add nanomaterials at a speed of 3g / min for continuous stirring. The dispersion is uniform, and the weight ratio of liquid medium to nanomaterials is 18:1;

[0089] (2) Add additives to the continuous stirring solution of step (1) in batches or once at a speed of 0.1g / min to obtain a paste, the consistency of which is 96mm, and the additives and nanomaterials The weight ratio is 20:1;

[0090] (3) the paste obtained in step (2) is mixed with long carbon chain nylon to obtain a premix;

[0091] (4) The premix of step (3) is fed into the screw extruder from the press...

Embodiment 2

[0095] In the present embodiment, the mass ratio of nanometer material and long carbon chain nylon is 10:100, and described long carbon chain nylon is selected from PA610, and the liquid medium adopted is trimethylpentane and water, trimethylpentane and The mass ratio of water is 3:1, the auxiliary agent that adopts is polyacrylic acid and pectin, and weight ratio is 1:1, and the nanometer material that adopts is nanometer lanthanum oxide, prepares nanocomposite material according to the following method:

[0096] (1) The liquid is stirred, and the nanomaterial is added at a speed of 10g / min to continuously stir and disperse evenly, and the weight ratio of the liquid medium to the nanomaterial is 100:1;

[0097] (2) Add auxiliary agent to the continuous stirring solution of step (1) with the speed of 0.5g / min, obtain paste, the consistency of described paste is 85mm, and the weight ratio of described auxiliary agent and nanometer material is 40:1;

[0098] (3) the paste obtai...

Embodiment 3

[0103] In the present embodiment, the mass ratio of nanometer material and long carbon chain nylon is 0.1:100, and described long carbon chain nylon is selected from PA612, and the liquid medium that adopts is water, and the auxiliary agent that adopts is dicyandiamide formaldehyde resin, adopts The nanomaterials are nano zirconia and nano erbium oxide, the mass ratio is 1:1, and the nanocomposite material is prepared according to the following method:

[0104] (1) The liquid medium is stirred, and the nanomaterial is added at a speed of 0.01g / min to continuously stir and disperse evenly, and the weight ratio of the liquid medium to the nanomaterial is 20:1;

[0105] (2) Add additives to the continuous stirring solution of step (1) at a speed of 10g / min to obtain a paste, the consistency of the paste is 42mm, and the weight ratio of the additives to nanomaterials is 50 :1;

[0106] (3) the paste obtained in step (2) is mixed with long carbon chain nylon to obtain a premix;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Consistency | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com