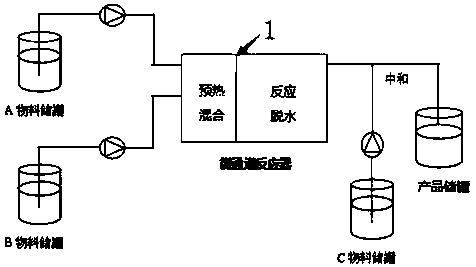

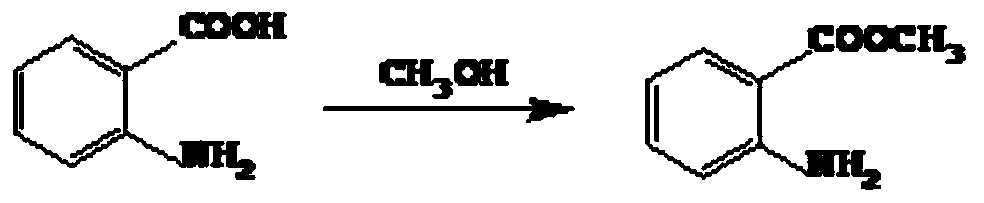

Method for continuously preparing methyl anthranilate

A technology for methyl anthranilate and anthranilic acid, which is applied in the field of organic compound preparation technology, can solve the problems of low purity and yield of methyl anthranilate, environmental pollution, etc., and achieve high product synthesis efficiency and improved Effect of Purity and Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

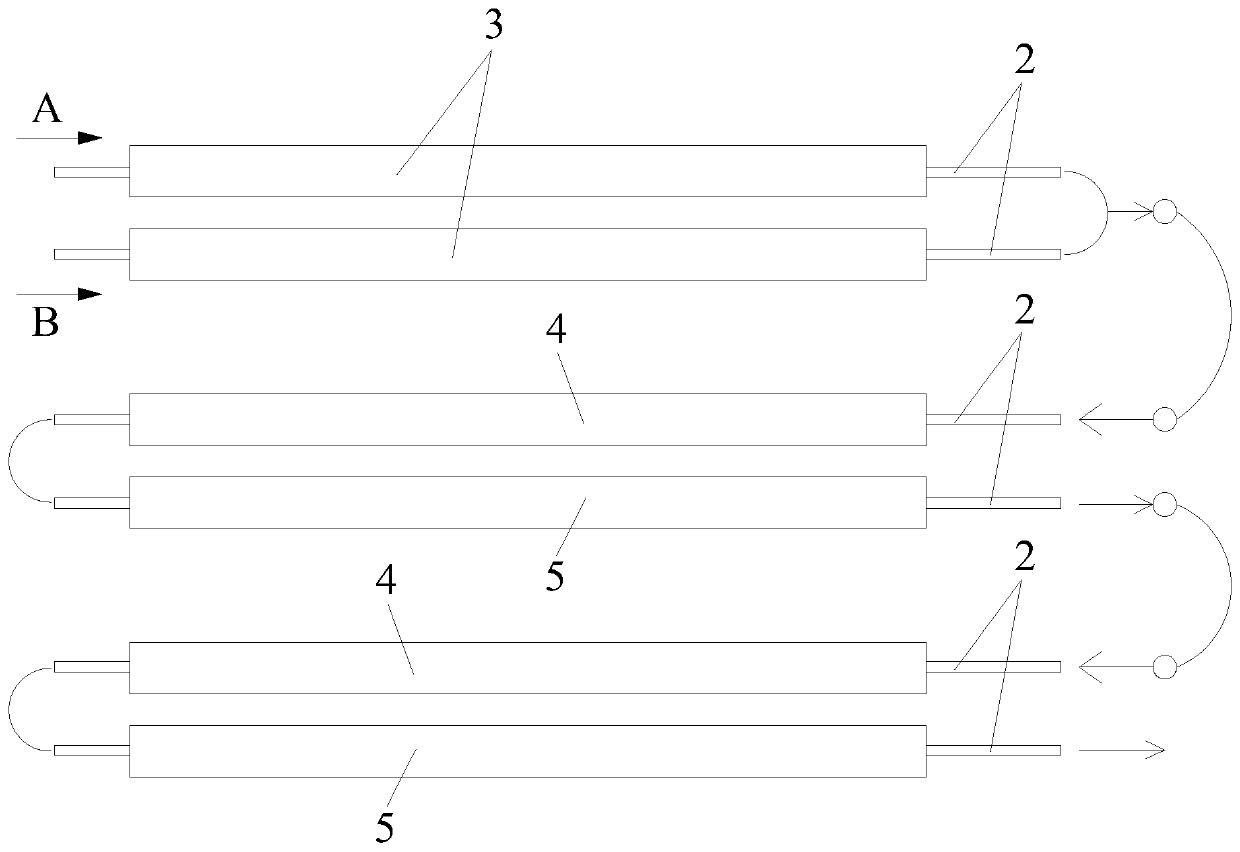

[0043] Pour the methanol solution of anthranilic acid and the concentrated sulfuric acid solution into the microchannel reactor respectively, and the two solutions are preheated by the preheating tube 3 and then mixed and then flow into the reaction tube 4 for reaction, and the reaction in the reaction tube 4 is set. The temperature is 65° C., the residence time of the methanol solution of anthranilic acid and the concentrated sulfuric acid solution in the microchannel reactor is 1 min, and the conversion rate of the methyl anthranilate flowing out from the mixed reaction chamber 1 is 90%.

Embodiment 2

[0045] Pour the methanol solution of anthranilic acid and the concentrated sulfuric acid solution into the microchannel reactor respectively, and the two solutions are preheated by the preheating tube 3 and then mixed and then flow into the reaction tube 4 for reaction, and the reaction in the reaction tube 4 is set. The temperature is 75° C., the residence time of the methanol solution of anthranilic acid and the concentrated sulfuric acid solution in the microchannel reactor is 1 min, and the conversion rate of the methyl anthranilate flowing out from the mixed reaction chamber 1 is 98%.

Embodiment 3

[0047] Pour the methanol solution of anthranilic acid and the concentrated sulfuric acid solution into the microchannel reactor respectively, and the two solutions are preheated by the preheating tube 3 and then mixed and then flow into the reaction tube 4 for reaction, and the reaction in the reaction tube 4 is set. The temperature is 85° C., the residence time of the methanol solution of anthranilic acid and the concentrated sulfuric acid solution in the microchannel reactor is 1 min, and the conversion rate of the methyl anthranilate flowing out from the mixing reaction chamber 1 is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com