Coarse aggregate concrete ink material for 3D printing and application thereof

A 3D printing and coarse aggregate technology, applied in the direction of additive processing, etc., can solve the problems of easy cracking cost, low flexural strength, easy to break, etc., to improve water retention, increase cementation strength, and reduce pumping resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

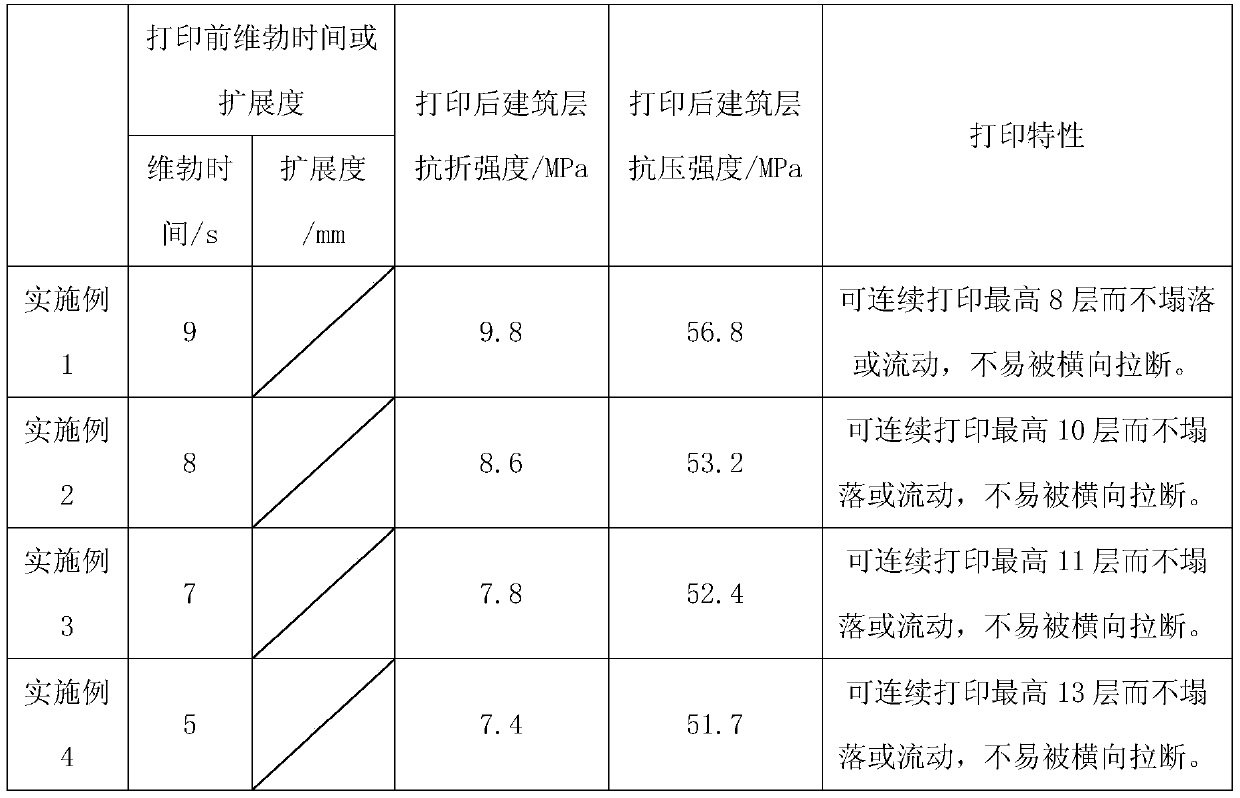

Embodiment 1

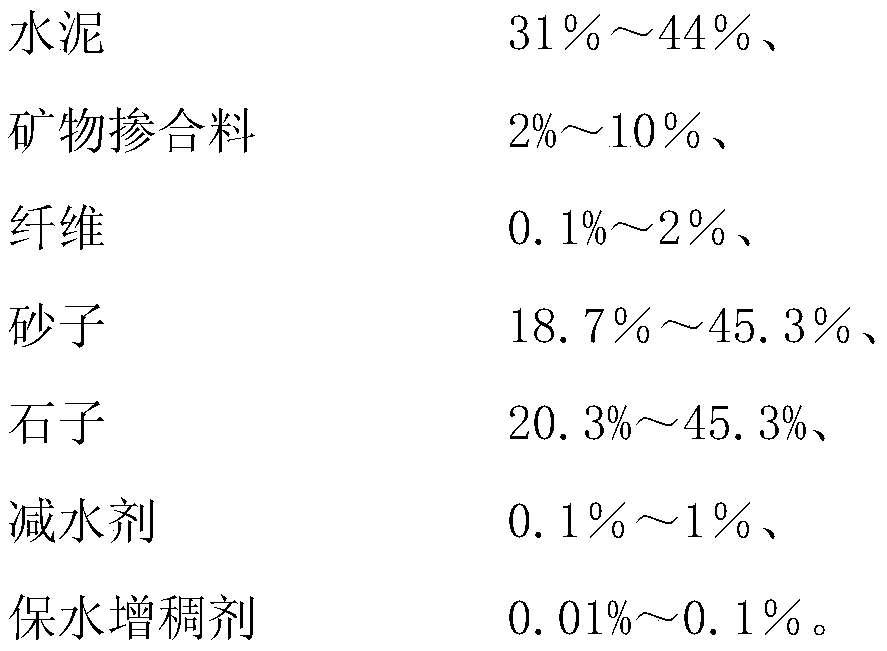

[0026] A coarse aggregate concrete ink material for 3D printing, which comprises the following components by weight percentage: 31% (27.14kg) Portland cement, 2% (1.75kg) silica fume, 2% (1.75kg) Limestone powder, 18.7% (17.86kg continuous grading) sand, 45.3% (39.66kg, continuous grading) 5-20mm particle size stones (continuous grading), 0.5% (0.44kg) PCA (Ⅶ) high performance water reducing Agent, 0.45% (0.39kg) polypropylene fiber, 0.05% (43.8g) water retention thickener propyl methyl cellulose ether.

[0027] in:

[0028] Portland cement has a specific surface area of 355m 2 / kg.

[0029] The specific surface area of silica fume is 20000m 2 / kg, the specific surface area of limestone powder is 330m 2 / kg.

[0030] The particle size of the sand ranges from 0.35 to 0.5 mm.

[0031] The particle size of the stones ranges from 5 to 20 mm.

[0032] The water reducer is PCA (Ⅶ) high-performance polycarboxylate water reducer with a solid content of 30% to 40%.

[003...

Embodiment 2

[0039] A coarse aggregate concrete ink material for 3D printing, the material includes the following components according to weight percentage: 33.5% (29.33kg) Portland cement, 5% (4.38kg) silica fume, 5% (4.38kg) Limestone powder, 18.7% (16.37kg continuous grading) sand, 36.7% (32.13kg, continuous grading) 5-20mm particle size stones (continuous grading), 0.5% (0.44kg) PCA (Ⅶ) high performance water reducing Agent, 0.59% (0.52kg) polypropylene fiber, 0.01% (8.8g) water retention thickener propyl methyl cellulose ether.

[0040] in:

[0041] Portland cement has a specific surface area of 355m 2 / kg.

[0042] The specific surface area of silica fume is 20000m 2 / kg, the specific surface area of limestone powder is 330m 2 / kg.

[0043] The particle size of the sand ranges from 0.35 to 0.5mm.

[0044] The particle size of the stones ranges from 5 to 20mm.

[0045] The water reducer is PCA (Ⅶ) high-performance polycarboxylate water reducer with a solid content of 30% ...

Embodiment 3

[0052] A coarse aggregate concrete ink material for 3D printing, which comprises the following components by weight percentage: 44% (38.5kg) Portland cement, 2% (1.75kg) silica fume, 2% (1.75kg) Limestone powder, 24.4% (21.36kg continuous grading) sand, 26.4% (23.11kg, continuous grading) 5-20mm particle size stones (continuous grading), 1% (0.88kg) PCA (Ⅶ) high performance water reducing Agent, 0.1% (87.5g) polypropylene fiber, 0.1% (87.6g) water retention thickener propyl methyl cellulose ether.

[0053] in:

[0054] Portland cement has a specific surface area of 355m 2 / kg.

[0055] The specific surface area of silica fume is 20000m 2 / kg, the specific surface area of limestone powder is 330m 2 / kg.

[0056] The particle size of the sand ranges from 0.35 to 0.5mm.

[0057] The particle size of the stones ranges from 5 to 20mm.

[0058] The water reducer is PCA (Ⅶ) high-performance polycarboxylate water reducer with a solid content of 30% to 40%.

[0059] The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com