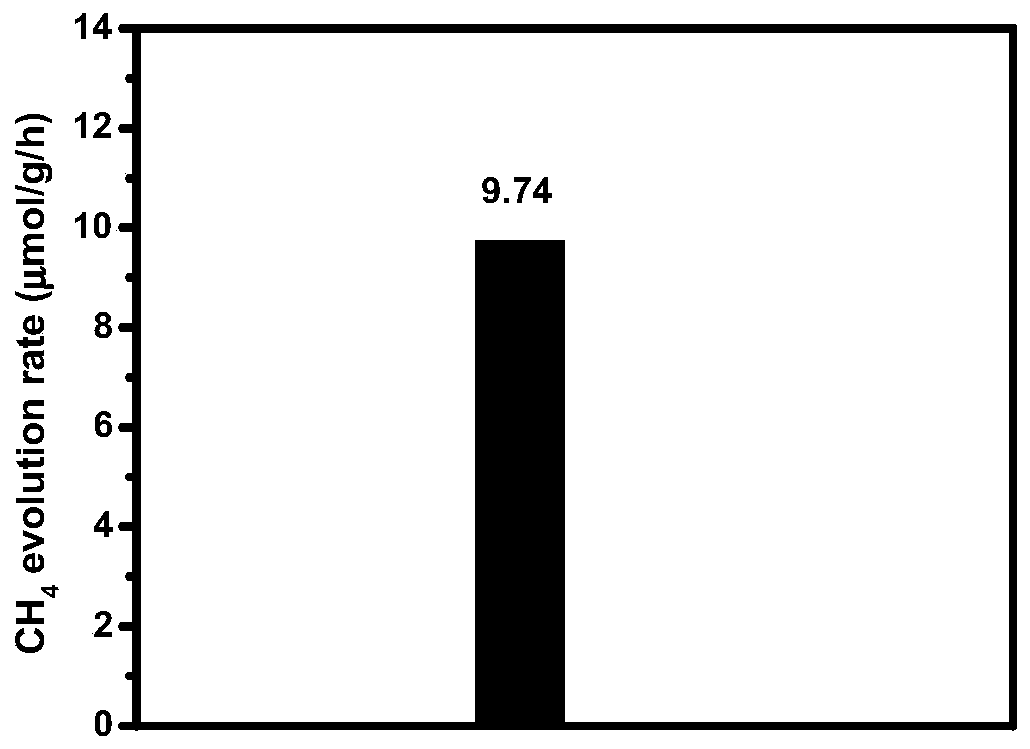

Carbon-coated synergistic carbon-sulfur-codoped SnO2 photocatalyst and preparation method thereof

A photocatalyst and carbon-coated technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of improved utilization, good ductility, and enhanced absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

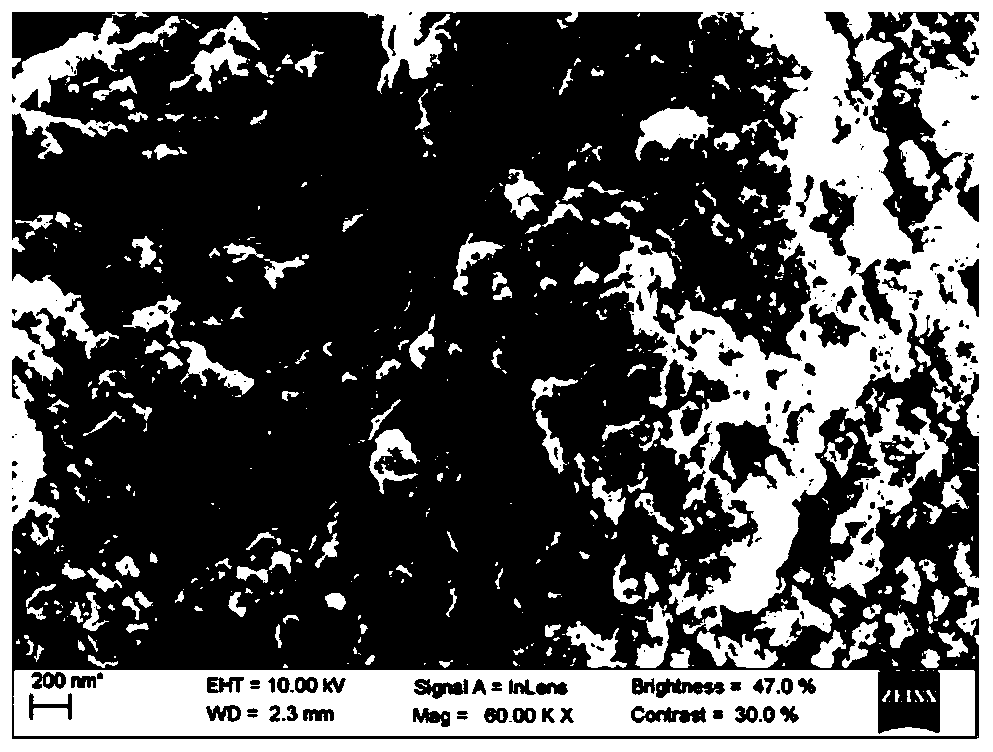

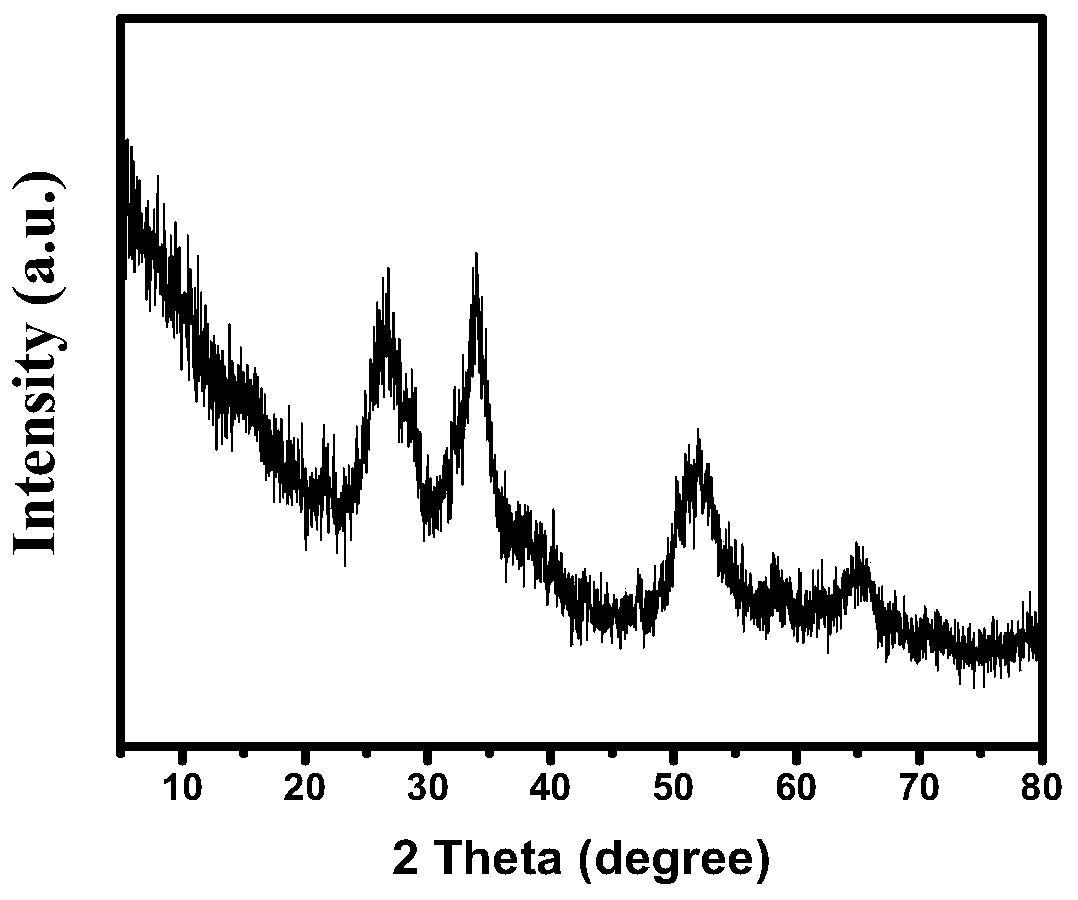

[0029] A carbon-coated synergistic carbon-sulfur co-doped SnO 2 The preparation method of photocatalyst comprises the following steps:

[0030](1) Preparation of MOF material precursor: Add 1mmol tin tetrachloride and 2mmol sulfur powder into deionized water, disperse evenly with an ultrasonic machine, then place the solution on a stirrer and stir, and slowly add 5mL Diethylenetriamine, and then stir the mixed solution for 30min, and finally transfer it to a reaction kettle lined with polytetrafluoroethylene, keep it at 80°C for 4h by solvothermal method, and centrifugally wash the obtained precipitate with deionized water after the reaction Several times, drying, and grinding into a uniform powder to obtain the MOF precursor;

[0031] (2) Carbon-coated synergistic carbon-sulfur co-doped SnO 2 Preparation of photocatalyst: first: put the MOF precursor powder prepared in step (1) into the furnace and raise the temperature to 300°C at a heating rate of 5°C / min and keep it for ...

Embodiment 2

[0033] A carbon-coated synergistic carbon-sulfur co-doped SnO 2 The preparation method of photocatalyst comprises the following steps:

[0034] (1) Preparation of MOF material precursor: Add 1.2mmol tin tetrachloride and 2.3mmol thioacetamide into deionized water, disperse evenly with an ultrasonic machine, then place the solution on a stirrer and stir, during the stirring process , slowly added 8 mL of ethylenediamine, then stirred the mixed solution for 30 min, and finally transferred it to a reaction kettle with a polytetrafluoroethylene liner, and kept it at 140 ° C for 8 h by solvothermal method. After the reaction, the obtained precipitate was deionized The MOF precursor was obtained by centrifugal washing with water and absolute ethanol for several times, drying, and grinding into a uniform powder;

[0035] (2) Carbon-coated synergistic carbon-sulfur co-doped SnO 2 Preparation of photocatalyst: first: put the MOF precursor powder prepared in step (1) into the furnace ...

Embodiment 3

[0037] A carbon-coated synergistic carbon-sulfur co-doped SnO 2 The preparation method of photocatalyst comprises the following steps:

[0038] (1) Preparation of MOF material precursor: Add 1.5mmol tin dichloride and 2mmol thiourea into deionized water, disperse evenly with an ultrasonic machine, then place the solution on a stirrer and stir, and slowly add 10mL of triethylenetetramine, then stirred the mixed solution for 30min, and finally transferred to a reaction kettle lined with polytetrafluoroethylene, kept at 180°C for 8h by solvothermal method, and filtered the obtained precipitate with deionized water after the reaction Wash several times, dry, and grind into a uniform powder to obtain the MOF precursor;

[0039] (2) Carbon-coated synergistic carbon-sulfur co-doped SnO 2 Preparation of photocatalyst: first: put the MOF precursor powder prepared in step (1) into the furnace and raise the temperature to 500°C at a heating rate of 8°C / min and keep it for 30min, then w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com