Printing ink, and preparation system and preparation method thereof

A printing ink and preparation system technology, applied in the direction of ink, chemical instruments and methods, mixers, etc., can solve the problems of low production efficiency, heavy labor, and long time consumption, and achieve dust elimination, uniform stirring effect, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

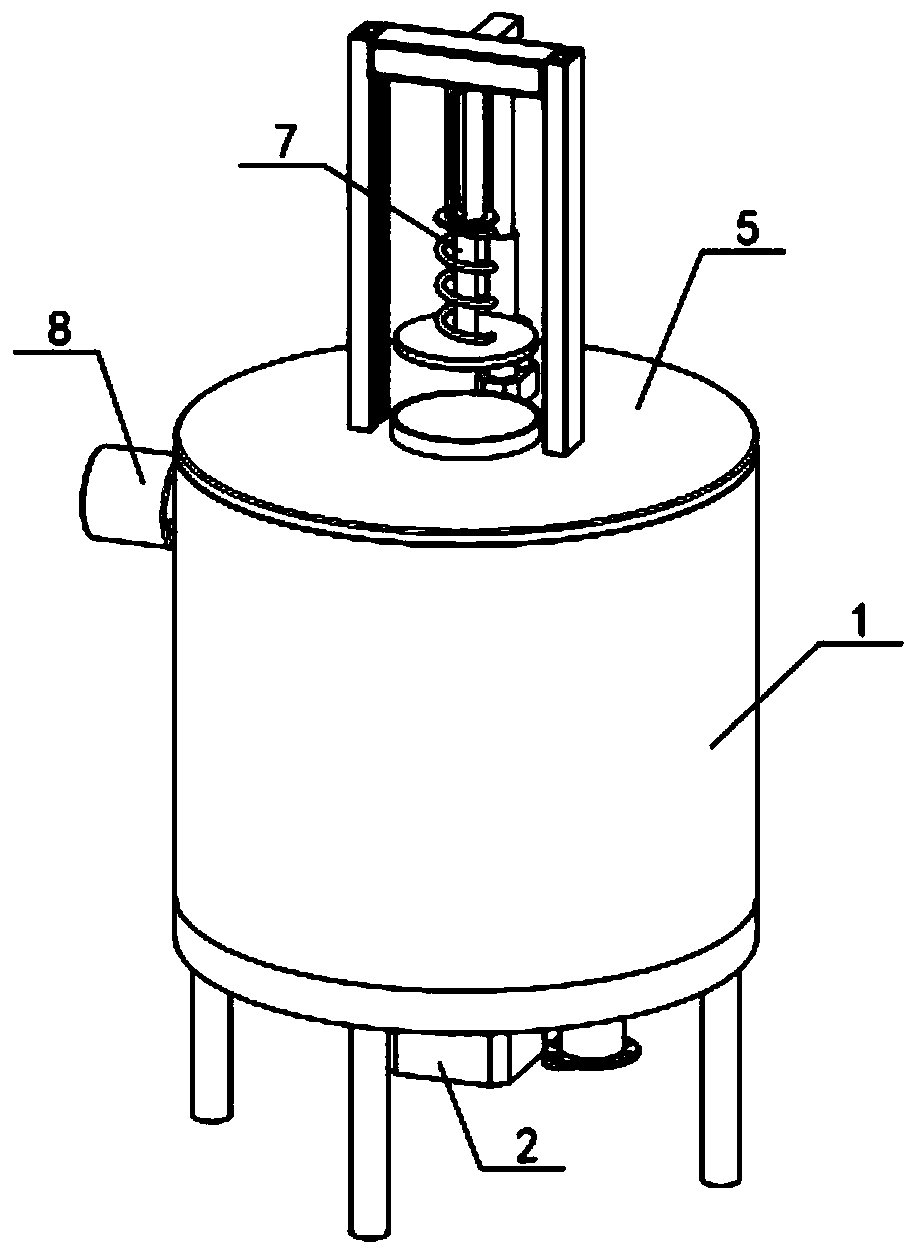

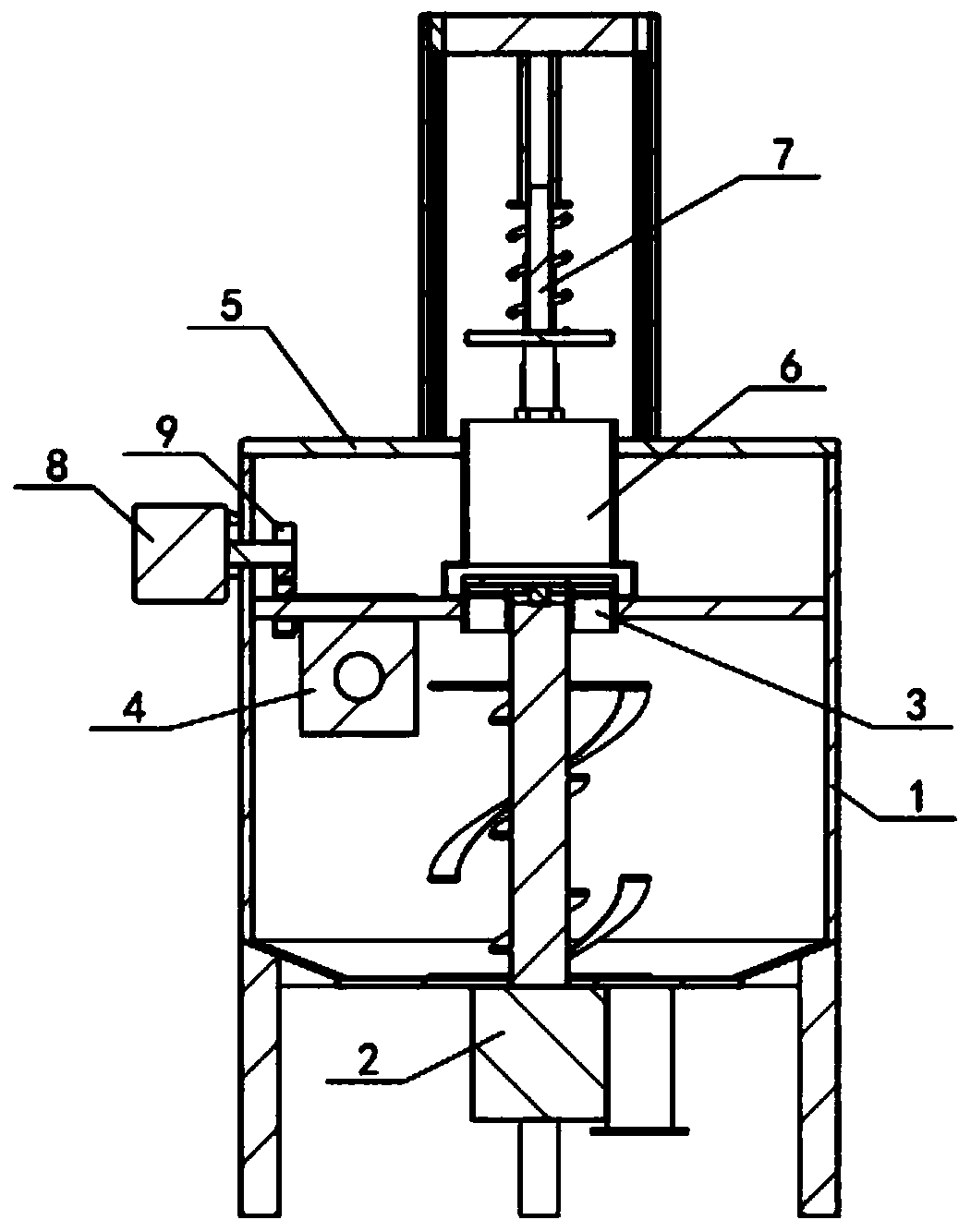

[0036] Such as Figure 1-11 As shown, a printing ink preparation system includes a stirring container 1, a grinding agitator 2, a center frame 3, a filter spoiler pocket 4, a top cover 5, a processing cylinder wall 6, a pressure applicator 7, a second motor 8 and a first Two gears 9, the lower end of the stirring container 1 is connected to the grinding agitator 2, the grinding agitator 2 is connected to the center frame 3 in rotation, the filter spoiler pocket 4 is connected to the stirring container 1 in rotation, and the top cover 5 is connected to the upper end of the stirring container 1 Fixedly connected, the processing cylinder wall 6 is fixedly connected with the middle part of the top cover 5, the pressure applicator 7 is connected with the top cover 5, and the second gear 9 is fixedly connected with the right end of the output shaft of the second motor 8. The raw materials are pre-grinded by the grinding disc 2-4, and the fine raw materials are automatically and even...

specific Embodiment approach 2

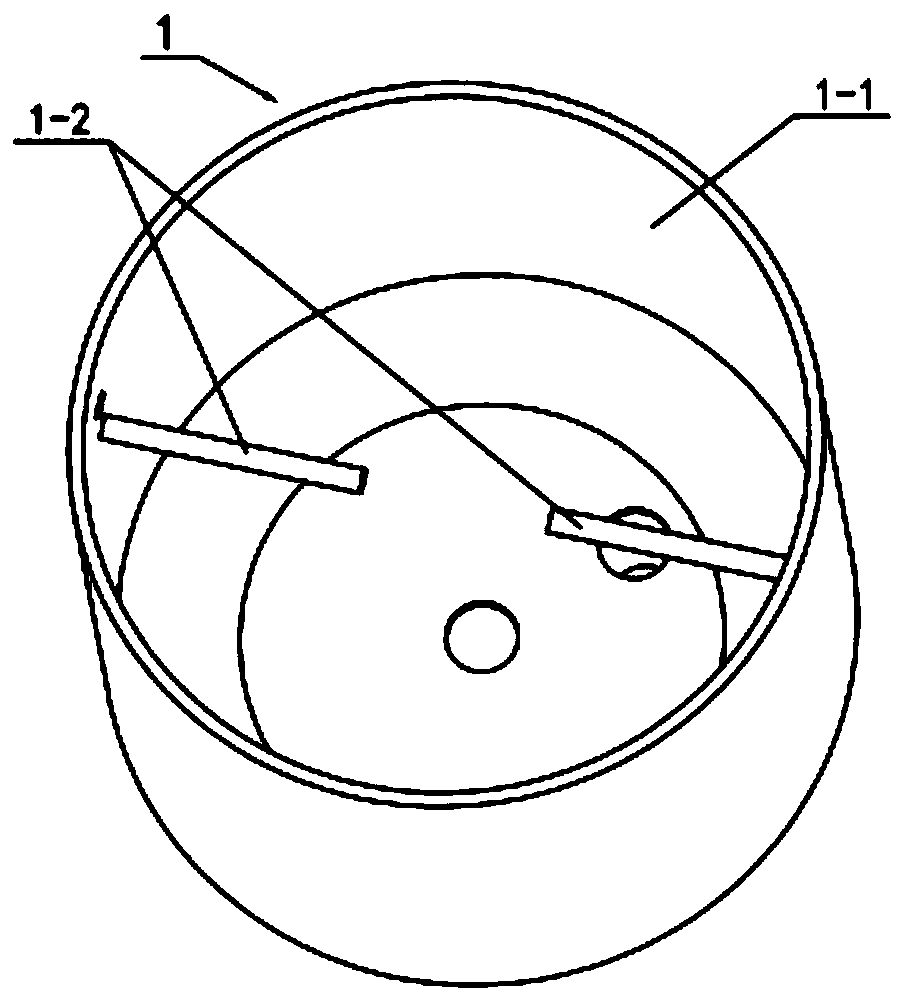

[0038] Such as Figure 1-11 As shown, the stirring container 1 includes a stirring container body 1-1, a fixed connecting rod 1-2 and an ink outlet pipe 1-3, and the left and right ends of the inner end surface of the stirring container body 1-1 are respectively fixedly connected to a fixed connecting rod. The rod 1-2, the ink outlet pipe 1-3 are fixedly connected and connected to the lower end of the stirring container body 1-1, and the ink outlet pipe 1-3 is provided with a valve; the second motor 8 is fixedly connected to the stirring container body 1-1. 1 the upper side of the left end, the left end of the output shaft of the second motor 8 is rotationally connected with the upper side of the stirring container body 1-1 left end. The valve can be a one-way valve, which is used to discharge the prepared printing ink, and the fixed rod 1-2 is used to fix the center frame 3, so that the center frame 3 becomes the installation platform for the upper end of the grinding agitato...

specific Embodiment approach 3

[0040] Such as Figure 1-11As shown, the grinding agitator 2 includes a first motor 2-1, a double helical stirring blade 2-2, a shaft 2-3 and a grinding disc 2-4, and the middle part of the output shaft of the first motor 2-1 is fixedly connected to the double The spiral stirring blade 2-2, the upper end of the output shaft of the first motor 2-1 is fixedly connected to the shaft 2-3, and the upper end of the shaft 2-3 is fixedly connected to the grinding disc 2-4; the first motor 2-1 is fixedly connected to the stirring container At the lower end of the main body 1-1, the output shaft of the first motor 2-1 is rotatably connected with the middle part of the lower end of the stirring vessel main body 1-1. The grinding disc 2-4 is used to grind solid materials such as pigments or fillers. When the first motor 2-1 is started, the output shaft of the first motor 2-1 drives the double helix stirring blade 2-2 to rotate, and the double helix stirring blade 2-2 Stir the raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com