A kind of preparation method of filling gel material

A cementing material and dry method technology, which is applied to the preparation of filling cementitious materials from lime sulfur residue and desulfurization ash. Using steel slag and slag, it can solve the problems that have not been applied on a large scale, and achieve good social and economic benefits. High waste slag content, the effect of improving the strength of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

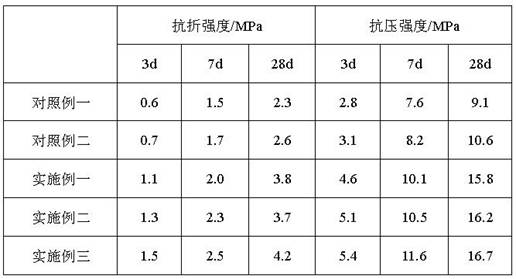

Embodiment 1

[0016]According to weight, 50% of the stone sulfur residue and 50% dry method, semi-dry deionium mix, calcination at 300 ° C for 50 min to obtain modified slag; steel slag, slag, modified slag, 26: 68: 6 ratio Grinding to a specific surface area 412m2 / kg gave gel material; the strength test was performed in accordance with GB / T17671-1999 "Cement Sand Intensity Test Method (ISO)".

Embodiment 2

[0018]According to the weight, 60% of the stone sulfur residue and 40% dry method, semi-dry detholar mixture, calcined at 450 ° C for 10 min to obtain modified slag; steel slag, slag, modified slag, 43: 55: 2 ratio Grinding to a specific surface area 496m2 / kg gave gel material; the strength test was performed in accordance with GB / T17671-1999 "Cement Sand Intensity Test Method (ISO)".

Embodiment 3

[0020]According to the weight, 70% of the stone sulfur residue and 30% dry method, semi-dry detholar mixture, calcined at 380 ° C for 30 min to obtain modified slag; steel slag, slag, modified slag Press 50:40:10 ratio Grinding to a specific surface area 539m2 / kg gave gel material; the strength test was performed in accordance with GB / T17671-1999 "Cement Sand Intensity Test Method (ISO)".

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com