Based on the improved aao sewage nitrogen and phosphorus removal device and process

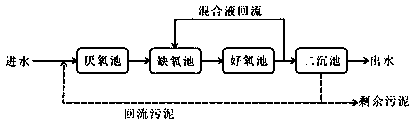

An improved technology for denitrification and phosphorus removal, applied in water/sewage treatment, multi-stage water/sewage treatment, biological water/sewage treatment, etc. It can solve the problems of unstable pH value, poor phosphorus removal, and instability , to achieve a good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

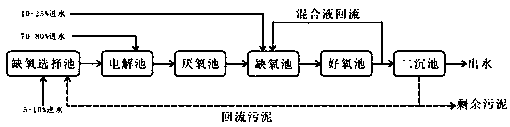

[0033] like figure 2 As shown, this embodiment provides an improved AAO sewage denitrification and phosphorus removal device, including anoxic selective pool, electrolytic pool, anaerobic pool, anoxic pool, aerobic pool and secondary sedimentation pool arranged in sequence along the sewage flow direction. pool, the anoxic selective pool, electrolytic pool, and anoxic pool are respectively connected with the sewage after desanding through pipelines; The outlet of the pool is connected with the anoxic selection pool through the sludge return channel.

[0034] The electrolytic cell is equipped with electrolytic water equipment with nano-diamond electrodes. When purifying and treating sewage, the anode can directly or indirectly generate hydroxyl radicals with strong oxidizing activity through low-voltage electrolytic reaction, because of its extremely high oxidizing capacity. Potential, its oxidizing ability is extremely strong, and it can undergo a rapid chain reaction with mo...

Embodiment 2

[0038] like figure 2 As shown, this example provides an improved AAO sewage nitrogen and phosphorus removal process, using the sewage nitrogen and phosphorus removal device as described in Example 1, the water temperature is controlled at 15°C to 20°C, and the activated sludge age is 15d. The specific process is:

[0039] S1. After desanding, the sewage is divided and sent to the anoxic selective pool, the electrolytic pool and the anoxic pool respectively through pipelines, wherein the water intake of the anoxic selective pool is 5%, and the water intake of the electrolytic pool is 75% , the water intake of the anoxic pool is 20%;

[0040] S2. Part of the activated sludge flows back into the anoxic selection tank through the sludge return channel, and the sludge return ratio is 100%. It is mixed with the desanded sewage directly diverted into the anoxic selection tank for denitrification treatment to eliminate The effect of nitrate in the return sludge on anaerobic phospho...

Embodiment 3

[0047] like figure 2 As shown, this example provides an improved AAO sewage nitrogen and phosphorus removal process, using the sewage nitrogen and phosphorus removal device as described in Example 1, the water temperature is controlled at 15°C to 20°C, and the activated sludge age is 15d. The specific process is:

[0048] S1. After desanding, the sewage is divided and sent to the anoxic selective pool, the electrolytic pool and the anoxic pool respectively through pipelines, wherein the water intake of the anoxic selective pool is 10%, and the water intake of the electrolytic pool is 80% , the water intake of the anoxic pool is 10%;

[0049] S2. Part of the activated sludge flows back into the anoxic selection tank through the sludge return channel, and the sludge return ratio is 90%. It is mixed with the desanded sewage directly diverted into the anoxic selection tank for denitrification treatment to eliminate The effect of nitrate in the return sludge on anaerobic phospho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com