Novel intelligent linkage type part fetching machine for die casting machine

An intelligent linkage, die-casting machine technology, applied in the field of die-casting machine auxiliary appliances, can solve the problems of wasting time, workers cannot directly contact the workpiece, and low die-casting efficiency, and achieves good effects, accelerates heat absorption rate, and improves work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

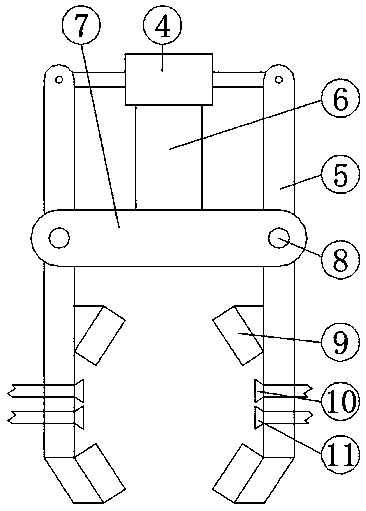

[0030] see Figure 1-4 , according to an embodiment of the present invention, a novel intelligent linkage pick-up machine for a die-casting machine includes a support plate 1, a translation device, a clamp device, an air pump 14, a water pump 15 and a PLC controller 13, and the four supports of the support plate 1 Support columns 2 are fixed under the corners, a translation device is provided under the support plate 1, a hydraulic cylinder 3 is fixed under the slider 24 of the translation device, and a clamp is fixed under the piston rod of the hydraulic cylinder 3. device, the clamp device includes a jaw cylinder 4, the jaw cylinder 4 is fixed under the piston rod of the hydraulic cylinder 3, and the telescopic rods at both ends of the jaw cylinder 4 are movable through a pin 8 and are provided with a connecting rod 5 , the jaw cylinder 4 is fixedly provided with a fixed rod 6, and the fixed rod 6 is fixedly provided with a connecting plate 7, and the two ends of the connecti...

Embodiment 2

[0033] see figure 1 with 4 , for the support column 2, the base 18 is fixed under the support column 2, and the four corners of the base 18 are provided with mounting holes 19; for the translation device, the translation device includes a slide rail 20, between the two ends of the slide rail 20, a screw rod 22 and a limit slide rod 23 are movable through bearings 21, and the outer wall of the screw rod 22 and the limit slide rod 23 are matched with a slider 24 and the The slider 24 is threadedly connected with the screw mandrel 22, the outer wall of one end of the slide rail 20 is fixedly provided with a motor 25, the rotating shaft of the motor 25 is fixedly connected with the screw mandrel 22, and the motor 25 is connected with the PLC control The device 13 is electrically connected; for the water spray head 10, the water spray head 10 is an atomizing spray head.

[0034] Through the above scheme of the present invention, the base 18 and the mounting hole 19 can facilitate...

Embodiment 3

[0036] see figure 1 with 3 , for the air pipe 16, the air pipe 16 and the water pipe 17 are flexible pipes; In other words, the water tank 12 is provided with a water inlet 27; for the water inlet 27, a water pipe 28 is connected to the water inlet 27, and an electromagnetic valve 29 is installed in the middle of the water pipe 28, and the water tank 12 A float-type liquid level gauge 30 is installed inside, and the electromagnetic valve 29 and the float-type liquid level gauge 30 are both electrically connected to the PLC controller 13 .

[0037]Through the above scheme of the present invention, the automatic tube retractor 26 can automatically rewind the water pipe 17 and the air pipe 16, prevent the water pipe 17 and the air pipe 16 from being entangled together, and can automatically detect the water level in the water tank 12 by using the float type liquid level gauge 30 , and the water level information is sent to the PLC controller 13, when the water level is low, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com