Gradient discharge, airflow crushing, classification and sorting device and method

A technology of jet crushing and sorting device, which is applied to the separation of solids from solids by airflow, chemical instruments and methods, solid separation, etc. Insufficient separation, low sorting precision and other problems, to achieve the effect of reasonable energy distribution, high sorting precision and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

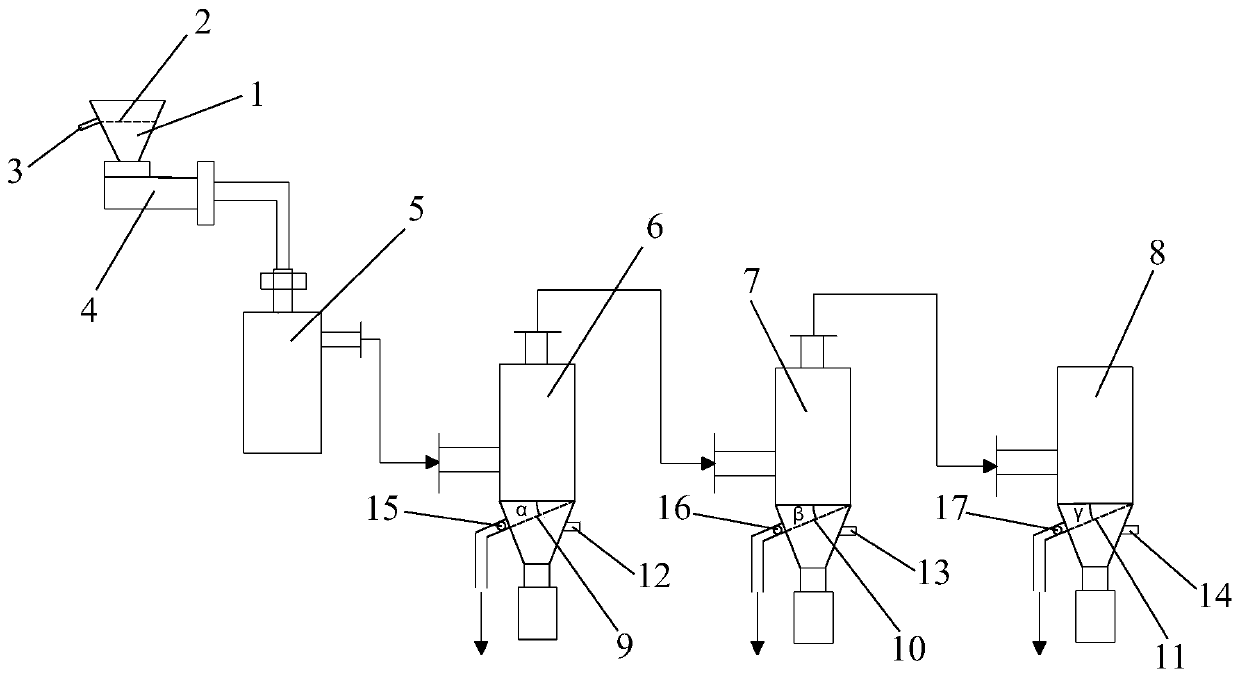

[0038] like figure 1A kind of cascade discharge airflow crushing classification and sorting device shown includes an airflow crushing unit and a cascade discharge unit, and the airflow crushing unit includes a feeding bin 1, a screw feeder 4 and an airflow pulverizer 5. A grading screen 2 is installed in the upper part of the feed bin 1, and the oversize outlet of the feed bin 1 is connected with an oversize discharge pipe 3, and the feed bin 1 is installed at the feed port of the screw feeder 4 , the discharge port of the screw feeder 4 is connected to the feed port of the airflow mill 5, and the airflow mill 5 is located below the screw feeder 4; the step discharge unit includes a primary classifier 6. The secondary classifier 7 and the three-stage classifier 8, the discharge port of the primary classifier 6 is connected with the feed port of the secondary classifier 7, and the discharge port of the secondary classifier 7 is connected to the three-stage classifier. The feed...

Embodiment 2

[0048] combine figure 1 , the present embodiment utilizes the method for classifying and sorting organic microscopic components and minerals in coal by means of the device described in Example 1, comprising the following steps:

[0049] Step 1. Feed the raw coal into the feeding bin 1. After being screened by the grading sieve 2, the oversize material is discharged through the oversize material discharge pipe 3, and the undersize material enters the screw feeder 4 and passes through the screw feeder. 4 is sent to the jet mill 5 for pulverization, and the raw coal particle size after pulverization by the jet mill 5 is ≤500 μm; the feeding speed of the screw feeder 4 is 120 g / min, and the crushing pressure of the jet mill 5 is 0.65 μm. MPa;

[0050] Step 2: The raw coal pulverized by the jet mill 5 enters the primary classifier 6 for the first classification and separation, and the fine coal that can pass through the gap between the classifying wheel blades of the primary class...

Embodiment 3

[0054] combine figure 1 , the present embodiment utilizes the method for classifying and sorting organic microscopic components and minerals in coal by means of the device described in Example 1, comprising the following steps:

[0055] Step 1. Feed the raw coal into the feeding bin 1. After being screened by the grading sieve 2, the oversize material is discharged through the oversize material discharge pipe 3, and the undersize material enters the screw feeder 4 and passes through the screw feeder. 4 is sent to the jet mill 5 for pulverization, and the raw coal particle size after pulverization by the jet mill 5 is ≤500 μm; the feeding speed of the screw feeder 4 is 50 g / min, and the crushing pressure of the jet mill 5 is 0.3 MPa;

[0056] Step 2: The raw coal pulverized by the jet mill 5 enters the primary classifier 6 for the first classification and separation, and the fine coal that can pass through the gap between the classifying wheel blades of the primary classifier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com